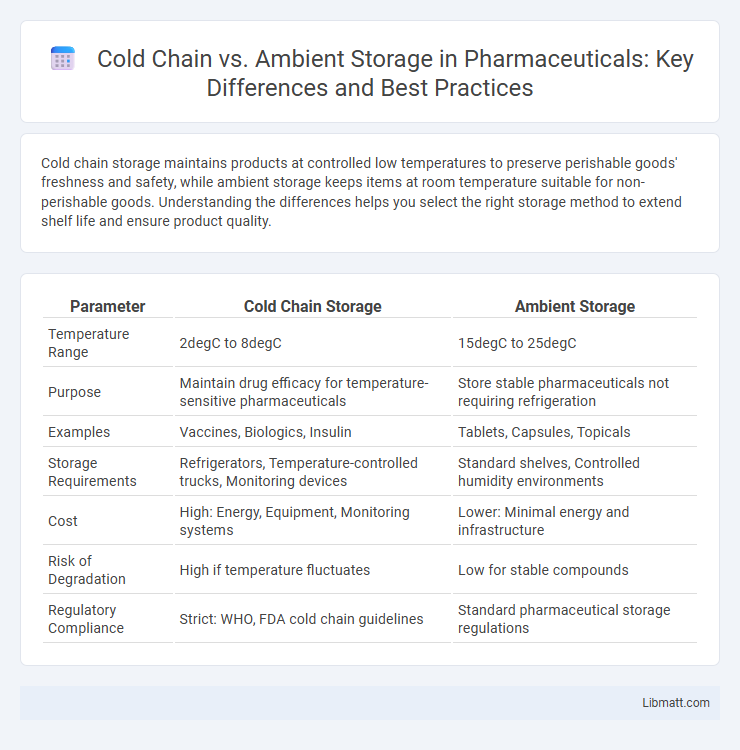

Cold chain storage maintains products at controlled low temperatures to preserve perishable goods' freshness and safety, while ambient storage keeps items at room temperature suitable for non-perishable goods. Understanding the differences helps you select the right storage method to extend shelf life and ensure product quality.

Table of Comparison

| Parameter | Cold Chain Storage | Ambient Storage |

|---|---|---|

| Temperature Range | 2degC to 8degC | 15degC to 25degC |

| Purpose | Maintain drug efficacy for temperature-sensitive pharmaceuticals | Store stable pharmaceuticals not requiring refrigeration |

| Examples | Vaccines, Biologics, Insulin | Tablets, Capsules, Topicals |

| Storage Requirements | Refrigerators, Temperature-controlled trucks, Monitoring devices | Standard shelves, Controlled humidity environments |

| Cost | High: Energy, Equipment, Monitoring systems | Lower: Minimal energy and infrastructure |

| Risk of Degradation | High if temperature fluctuates | Low for stable compounds |

| Regulatory Compliance | Strict: WHO, FDA cold chain guidelines | Standard pharmaceutical storage regulations |

Introduction to Cold Chain and Ambient Storage

Cold chain storage involves maintaining products at controlled low temperatures, typically between 2degC and 8degC, to preserve the quality and safety of temperature-sensitive items like vaccines, pharmaceuticals, and perishable foods. Ambient storage, by contrast, keeps products at room temperature, usually between 15degC and 25degC, suitable for goods that do not require refrigeration such as canned foods and certain dry goods. Understanding the differences between cold chain and ambient storage helps optimize your storage solutions based on product requirements and shelf-life needs.

Understanding Cold Chain Logistics

Cold chain logistics involves maintaining a temperature-controlled supply chain to preserve the quality and safety of perishable goods such as pharmaceuticals, food, and chemicals. Ambient storage keeps products at stable, non-refrigerated temperatures, ideal for items that do not require chilling or freezing. Effective cold chain management minimizes spoilage, extends shelf life, and ensures compliance with regulatory standards for temperature-sensitive shipments.

What Is Ambient Storage?

Ambient storage refers to storing products at room temperature, typically between 20degC and 25degC, without the need for refrigeration or freezing. It is ideal for items that remain stable and safe under standard environmental conditions, such as canned foods, dry goods, and certain pharmaceuticals. You must consider the specific temperature, humidity, and light requirements of your products to ensure optimal quality and shelf life in ambient storage.

Key Differences Between Cold Chain and Ambient Storage

Cold chain storage maintains products at controlled low temperatures, typically between 2degC and 8degC, essential for perishable goods like vaccines, pharmaceuticals, and fresh food to preserve efficacy and safety. Ambient storage keeps goods at room temperature, generally ranging from 15degC to 25degC, suitable for non-perishable items such as grains, canned foods, and some chemicals. Key differences lie in temperature control requirements, cost implications, and the type of products each method can effectively preserve.

Temperature Requirements and Control

Cold chain storage demands strict temperature control, generally ranging from 2degC to 8degC for refrigerated products and -20degC or lower for frozen goods, ensuring the preservation of perishable items such as pharmaceuticals and food. Ambient storage maintains temperatures typically between 15degC and 25degC, suitable for products stable at room temperature without significant risk of degradation. Advanced monitoring systems and insulated packaging are critical in cold chain logistics to prevent temperature fluctuations that can compromise product integrity.

Product Types Suited for Each Storage Method

Cold chain storage is essential for perishable products like vaccines, dairy, pharmaceuticals, and fresh produce that require consistent low temperatures to maintain potency and freshness. Ambient storage suits shelf-stable items such as canned goods, grains, spices, and dry snacks that can withstand fluctuating temperatures without spoiling. Your choice between cold chain and ambient storage depends on the specific product type and its temperature sensitivity to ensure quality and safety.

Cost Comparison: Cold Chain vs Ambient Storage

Cold chain storage incurs higher costs due to energy-intensive refrigeration, specialized equipment, and continuous temperature monitoring requirements. Ambient storage offers a cost-effective alternative with lower operational expenses, as it relies on room temperature conditions and minimal infrastructure. However, the choice depends on product sensitivity, as cold chain ensures quality for perishable goods despite the increased financial investment.

Impact on Shelf Life and Product Quality

Cold chain storage significantly extends shelf life by maintaining consistent low temperatures that inhibit microbial growth and enzymatic activity, preserving product freshness and quality. Ambient storage, subject to fluctuating temperatures, accelerates spoilage processes and reduces shelf life, especially for perishable goods like pharmaceuticals, food, and biologics. Maintaining an optimal cold chain environment ensures product integrity and efficacy, crucial for regulatory compliance and consumer safety.

Regulatory Compliance and Safety Standards

Cold chain storage strictly adheres to regulatory compliance standards such as FDA's Current Good Manufacturing Practices (cGMP) and WHO guidelines to ensure temperature-sensitive products like vaccines and biologics maintain efficacy and safety. Ambient storage follows less stringent protocols but must comply with general safety standards, including ISO 9001 certification and local health regulations, to prevent contamination and preserve product integrity. Both methods require documented monitoring systems and validated procedures to meet regulatory inspections and ensure consumer safety.

Choosing the Right Storage Solution for Your Business

Selecting the appropriate storage solution depends on the specific temperature requirements of your products, with cold chain storage maintaining temperatures typically between 2degC to 8degC to preserve perishable goods like pharmaceuticals and food items. Ambient storage suits non-perishable products that remain stable at room temperature, generally between 15degC to 25degC, reducing energy costs and simplifying logistics. Your decision should consider product sensitivity, regulatory compliance, and cost-efficiency to optimize supply chain reliability and quality assurance.

Cold Chain vs Ambient Storage Infographic

libmatt.com

libmatt.com