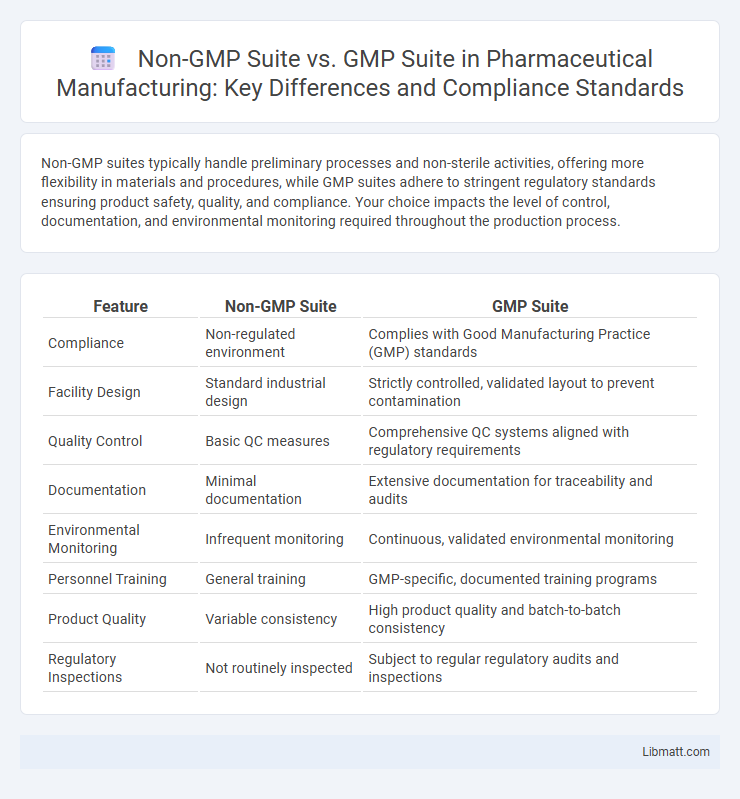

Non-GMP suites typically handle preliminary processes and non-sterile activities, offering more flexibility in materials and procedures, while GMP suites adhere to stringent regulatory standards ensuring product safety, quality, and compliance. Your choice impacts the level of control, documentation, and environmental monitoring required throughout the production process.

Table of Comparison

| Feature | Non-GMP Suite | GMP Suite |

|---|---|---|

| Compliance | Non-regulated environment | Complies with Good Manufacturing Practice (GMP) standards |

| Facility Design | Standard industrial design | Strictly controlled, validated layout to prevent contamination |

| Quality Control | Basic QC measures | Comprehensive QC systems aligned with regulatory requirements |

| Documentation | Minimal documentation | Extensive documentation for traceability and audits |

| Environmental Monitoring | Infrequent monitoring | Continuous, validated environmental monitoring |

| Personnel Training | General training | GMP-specific, documented training programs |

| Product Quality | Variable consistency | High product quality and batch-to-batch consistency |

| Regulatory Inspections | Not routinely inspected | Subject to regular regulatory audits and inspections |

Understanding GMP and Non-GMP Suites

GMP suites comply with Good Manufacturing Practices regulations essential for producing pharmaceutical and medical products, ensuring product safety and quality through stringent environmental controls and documentation. Non-GMP suites operate without these regulatory requirements, typically used for research, development, or non-sterile processes where compliance is not mandatory. The key differences lie in validation standards, cleanliness levels, and regulatory oversight, which directly impact production environments and product approval pathways.

Key Differences Between GMP and Non-GMP Suites

GMP suites follow strict regulatory guidelines such as FDA and EMA standards to ensure product quality, safety, and traceability, making them essential for pharmaceutical manufacturing. Non-GMP suites have more flexible protocols with less stringent documentation and environmental control requirements, suitable for research, development, or early-stage production. Your choice between a GMP and non-GMP suite depends on the intended application, regulatory obligations, and quality assurance needs.

Regulatory Requirements: GMP vs Non-GMP

GMP suites adhere to strict regulatory requirements ensuring product quality, safety, and consistency as mandated by agencies like the FDA and EMA, including validated processes and comprehensive documentation. Non-GMP suites operate with fewer regulatory constraints, allowing more flexibility for research and development activities but are not designed for manufacturing products intended for human use or commercial distribution. Your choice between GMP and Non-GMP suites depends on whether compliance with these rigorous standards is necessary for regulatory approval or commercial production.

Facility Design and Infrastructure

Non-GMP suites feature flexible facility design with basic infrastructure focused on research and development, allowing more adaptable layouts and less stringent environmental controls. GMP suites require highly controlled, validated environments with strict adherence to regulatory standards, including precise HVAC systems, cleanroom classifications, and contamination control measures. Your choice between these depends on the need for compliance with Good Manufacturing Practice regulations, impacting the complexity and cost of the infrastructure.

Quality Assurance and Documentation

Non-GMP suites follow basic quality assurance protocols with flexible documentation standards primarily suited for research and development phases, allowing modification and experimentation without stringent regulatory oversight. In contrast, GMP suites enforce rigorous quality assurance systems, including validated processes, standardized operating procedures, and comprehensive, traceable documentation to ensure product safety, efficacy, and compliance with regulatory agencies such as the FDA or EMA. The documentation in GMP suites is meticulously maintained, including batch records, equipment logs, and deviation reports, which are critical for audits and regulatory inspections.

Production Processes in GMP vs Non-GMP Suites

Production processes in GMP suites adhere strictly to validated protocols, comprehensive documentation, and rigorous quality control standards to ensure product safety and regulatory compliance. Non-GMP suites allow for more flexible workflows and experimentation without the same level of documentation or quality assurance requirements. This distinction ensures GMP suites are essential for manufacturing pharmaceuticals, biologics, and other regulated products, while Non-GMP suites support research, development, and pilot-scale activities.

Cost Implications of GMP and Non-GMP Suites

GMP suites require stringent regulatory compliance, specialized equipment, and validation processes, significantly increasing operational and maintenance costs compared to non-GMP suites. Non-GMP suites offer a cost-effective alternative by allowing more flexibility in facility standards and reduced documentation requirements, making them suitable for early-stage development or non-clinical work. Your choice between GMP and non-GMP suites directly impacts budget allocation, with GMP environments demanding higher initial and ongoing investments to ensure product quality and regulatory adherence.

Use Cases: When to Choose Non-GMP or GMP

Non-GMP suites are ideal for early-stage research, product development, and process optimization where regulatory compliance is not mandatory, enabling flexibility and cost-efficiency. GMP suites are essential for manufacturing commercial pharmaceutical products, ensuring strict quality control, traceability, and adherence to regulatory standards required by agencies like the FDA or EMA. Choosing between the two depends on the production stage, regulatory requirements, and the intended use of the final product.

Challenges and Risks of Each Suite Type

Non-GMP suites face challenges related to contamination control due to less stringent environmental and procedural regulations, increasing the risk of cross-contamination and batch variability. GMP suites require rigorous compliance with regulatory standards, demanding extensive documentation, validation, and high operational costs, which can slow down production flexibility. Both suite types carry risks: non-GMP suites may compromise product quality and safety, while GMP suites pose challenges in maintaining strict cleanliness and regulatory adherence, potentially leading to costly compliance failures.

Future Trends in GMP and Non-GMP Facilities

Future trends in GMP and Non-GMP facilities emphasize increasing automation through AI-driven quality control systems and real-time data analytics to enhance manufacturing precision and compliance. Integration of modular cleanroom designs enables rapid scaling and flexibility, addressing evolving regulatory landscapes and production demands. The convergence of digital twin technology and continuous manufacturing processes will further streamline validation and reduce downtime in both GMP and Non-GMP suites.

Non-GMP suite vs GMP suite Infographic

libmatt.com

libmatt.com