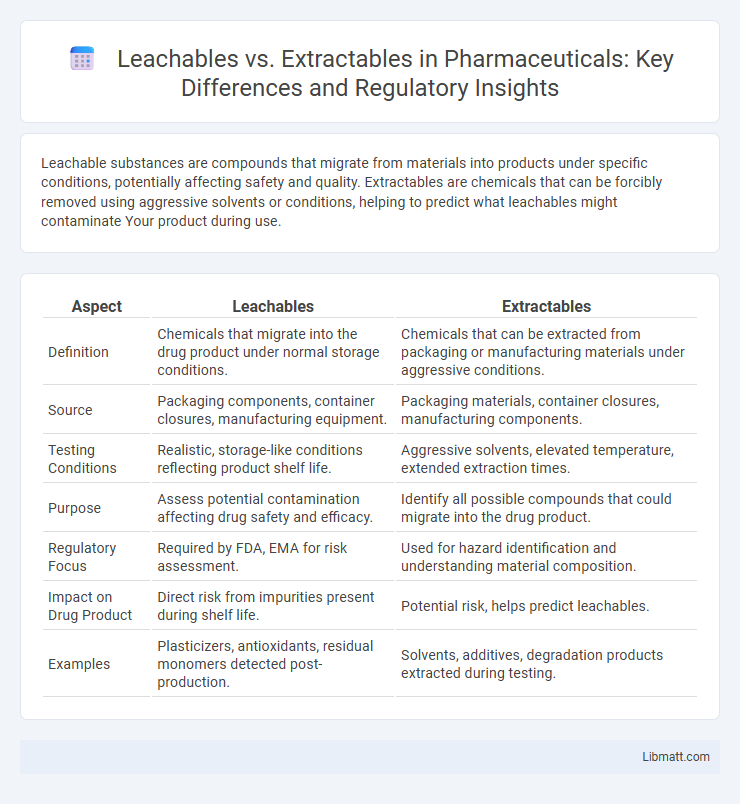

Leachable substances are compounds that migrate from materials into products under specific conditions, potentially affecting safety and quality. Extractables are chemicals that can be forcibly removed using aggressive solvents or conditions, helping to predict what leachables might contaminate Your product during use.

Table of Comparison

| Aspect | Leachables | Extractables |

|---|---|---|

| Definition | Chemicals that migrate into the drug product under normal storage conditions. | Chemicals that can be extracted from packaging or manufacturing materials under aggressive conditions. |

| Source | Packaging components, container closures, manufacturing equipment. | Packaging materials, container closures, manufacturing components. |

| Testing Conditions | Realistic, storage-like conditions reflecting product shelf life. | Aggressive solvents, elevated temperature, extended extraction times. |

| Purpose | Assess potential contamination affecting drug safety and efficacy. | Identify all possible compounds that could migrate into the drug product. |

| Regulatory Focus | Required by FDA, EMA for risk assessment. | Used for hazard identification and understanding material composition. |

| Impact on Drug Product | Direct risk from impurities present during shelf life. | Potential risk, helps predict leachables. |

| Examples | Plasticizers, antioxidants, residual monomers detected post-production. | Solvents, additives, degradation products extracted during testing. |

Introduction to Leachables and Extractables

Leachables are chemical substances that migrate into a product under normal conditions, while extractables are compounds obtained from materials using aggressive solvents or conditions in a lab setting. Understanding the difference between leachables and extractables is crucial for assessing potential contamination and ensuring product safety. Your quality control process benefits from identifying extractables first, which helps predict possible leachables during product use.

Definitions: What Are Leachables and Extractables?

Leachables are chemical compounds that migrate from packaging materials or device components into a drug product during storage or use, potentially impacting safety and efficacy. Extractables are substances that can be forcibly removed from materials using solvents under controlled laboratory conditions, representing the worst-case scenario of possible contaminants. Understanding the distinction between leachables and extractables is essential for your pharmaceutical product's quality control and regulatory compliance.

Key Differences Between Leachables and Extractables

Leachables are chemical compounds that migrate into drug products during storage or use, posing a potential risk to safety and efficacy, while extractables are substances released from container closure systems under aggressive laboratory conditions. Extractables are identified through controlled extraction studies, providing a profile of potential contaminants, whereas leachables are detected during real-time stability or usage studies reflecting actual exposure. Understanding the key differences between leachables and extractables is essential for ensuring Your pharmaceutical product's safety and regulatory compliance.

Importance in Pharmaceutical and Medical Device Industries

Leachables and extractables are critical for ensuring safety and compliance in pharmaceutical and medical device industries, as they represent chemical compounds that can migrate from materials into drug products or bodily fluids. Monitoring these substances helps prevent contamination, adverse reactions, and ensures product integrity by meeting regulatory guidelines such as FDA and EMA standards. Effective control of leachables and extractables supports risk assessment, biocompatibility, and quality assurance throughout the product lifecycle.

Sources of Leachables and Extractables

Leachables originate from materials such as plastic containers, tubing, and packaging components that come into direct contact with pharmaceuticals or food products. Extractables are chemical compounds that can be forced out from these materials under aggressive laboratory conditions, often involving solvents, heat, or extended exposure times. Understanding sources of leachables and extractables is critical for ensuring product safety, particularly in the pharmaceutical and medical device industries, where packaging and device materials may impact product purity.

Analytical Methods for Detection and Quantification

Analytical methods for detecting and quantifying leachables and extractables include gas chromatography-mass spectrometry (GC-MS), liquid chromatography-mass spectrometry (LC-MS), and nuclear magnetic resonance (NMR) spectroscopy, which provide detailed compositional and quantitative information. Techniques like headspace GC-MS are especially useful for volatile compounds, while LC-MS excels in identifying non-volatile, polar substances. Your choice of method depends on the chemical nature of potential contaminants and regulatory requirements for sensitivity and specificity.

Regulatory Guidelines and Compliance Standards

Regulatory guidelines for leachables and extractables are defined by agencies such as the FDA, EMA, and USP, emphasizing the identification and quantification of chemical compounds migrating from packaging or manufacturing materials into drug products. Compliance standards require thorough risk assessments, analytical method validation, and adherence to threshold limits outlined in ICH Q3E and USP <1663> for extractables and USP <1664> for leachables. Meeting these regulatory frameworks ensures patient safety and product efficacy by controlling potential contaminants in pharmaceutical formulations.

Risk Assessment and Impact on Product Safety

Leachables and extractables are chemical compounds that can migrate from packaging materials into drug products, presenting potential safety risks. Comprehensive risk assessment involves identifying and quantifying these compounds to evaluate their toxicological impact and ensure patient safety. Understanding the nature and concentration of leachables versus extractables is critical to developing effective control strategies that maintain product integrity and regulatory compliance.

Case Studies: Managing Leachables and Extractables

Effective management of leachables and extractables in pharmaceuticals hinges on thorough case studies that analyze material compatibility and identify potential contaminants. Implementing targeted analytical techniques, such as mass spectrometry and chromatographic profiling, allows you to detect and quantify harmful compounds originating from packaging, processing equipment, or formulation components. Case studies demonstrate risk mitigation strategies, ensuring product safety and regulatory compliance by addressing specific leachable and extractable challenges encountered in drug development and manufacturing.

Best Practices for Mitigation and Quality Assurance

Leachable and extractable compounds require stringent control to ensure product safety and quality, emphasizing robust material selection and comprehensive analytical testing. Implementing standardized protocols for extraction studies, simulating worst-case conditions, helps identify potential contaminants early in the development process. Your quality assurance strategy should include regular monitoring, risk assessment, and validation of cleaning procedures to mitigate leachables and extractables effectively.

Leachable vs extractable Infographic

libmatt.com

libmatt.com