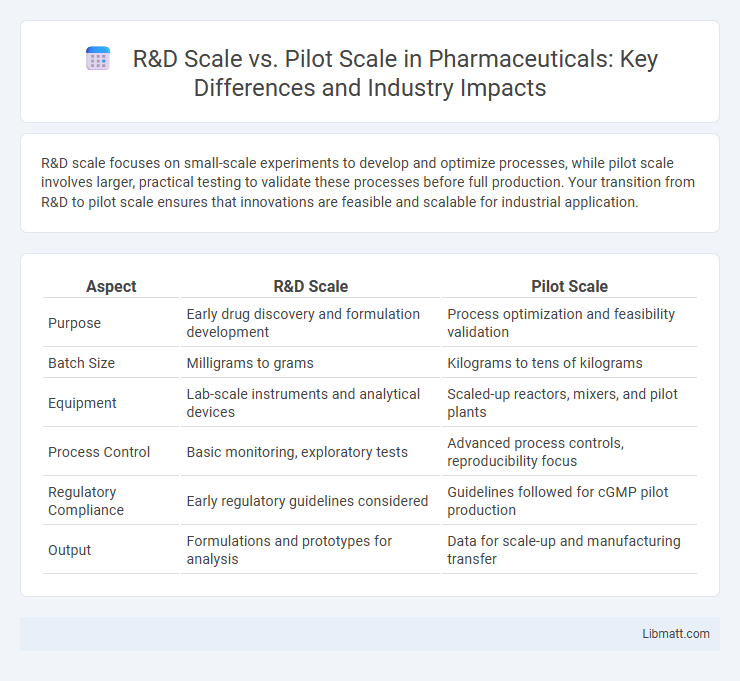

R&D scale focuses on small-scale experiments to develop and optimize processes, while pilot scale involves larger, practical testing to validate these processes before full production. Your transition from R&D to pilot scale ensures that innovations are feasible and scalable for industrial application.

Table of Comparison

| Aspect | R&D Scale | Pilot Scale |

|---|---|---|

| Purpose | Early drug discovery and formulation development | Process optimization and feasibility validation |

| Batch Size | Milligrams to grams | Kilograms to tens of kilograms |

| Equipment | Lab-scale instruments and analytical devices | Scaled-up reactors, mixers, and pilot plants |

| Process Control | Basic monitoring, exploratory tests | Advanced process controls, reproducibility focus |

| Regulatory Compliance | Early regulatory guidelines considered | Guidelines followed for cGMP pilot production |

| Output | Formulations and prototypes for analysis | Data for scale-up and manufacturing transfer |

Understanding R&D Scale and Pilot Scale

R&D Scale refers to experimental and developmental activities conducted to innovate or improve products, typically involving small quantities and controlled conditions. Pilot Scale involves scaling up the R&D findings to a semi-industrial level, enabling evaluation of production feasibility and process optimization before full-scale manufacturing. Your understanding of the differences between R&D Scale and Pilot Scale is crucial for effectively transitioning from concept to commercialization.

Key Differences Between R&D and Pilot Scales

R&D scale primarily focuses on small batch experiments to develop and optimize processes or products, using limited raw materials and flexible methodologies. Pilot scale bridges the gap between lab research and full-scale production, involving larger quantities and semi-industrial equipment to validate process scalability and identify potential operational challenges. Understanding these key differences helps you design efficient workflows that minimize risk before commercial manufacturing.

Purpose and Objectives of R&D Scale

R&D scale focuses on developing and testing new concepts, materials, or processes under controlled laboratory conditions to validate feasibility and identify potential issues early. Its primary objective is to generate data and insights that guide process optimization and scale-up decisions, minimizing risks before moving to pilot scale. Your innovations rely on precise R&D scale experiments to ensure reliable and efficient transition toward larger-scale production.

Goals and Functions of Pilot Scale

Pilot scale bridges the gap between R&D scale and full-scale production by validating processes under conditions that closely mimic industrial operations. Its primary goals include assessing feasibility, optimizing parameters for scalability, and identifying potential issues before commercialization. Your investment in pilot scale ensures reliable process data and risk mitigation, paving the way for successful large-scale manufacturing.

Equipment and Infrastructure Requirements

R&D scale operations typically involve smaller, more flexible equipment designed for experimentation and process development, requiring minimal infrastructure and adaptability for frequent changes. Pilot scale demands larger, semi-continuous equipment that closely mimics production conditions, necessitating more robust infrastructure like controlled environments and utilities to support extended runs. Your choice in scale impacts the complexity, cost, and scalability of equipment and infrastructure needed for successful process transition.

Process Optimization: R&D vs Pilot Scale

Process optimization in R&D scale focuses on identifying optimal reaction conditions and formulations using small batch experiments, allowing rapid iteration and data collection. Pilot scale expands these conditions to larger volumes, emphasizing reproducibility, scalability, and process control to ensure consistency and feasibility for commercial production. Your ability to translate R&D findings into robust pilot-scale operations directly impacts successful scale-up and product commercialization.

Challenges Faced in Scaling Up

Scaling up from R&D scale to pilot scale presents challenges such as ensuring reproducibility of results, maintaining product quality, and managing increased operational complexity. Variability in raw materials and process conditions can impact consistency and yield during scale-up. Your team must address equipment limitations and optimize parameters to successfully transition processes without compromising efficiency or safety.

Cost Implications: R&D Scale vs Pilot Scale

R&D scale operations typically incur lower costs due to smaller batch sizes and limited resource consumption, making them ideal for initial experiments and feasibility studies. Pilot scale processes involve higher expenses as they require larger volumes, advanced equipment, and more comprehensive safety and quality controls to simulate full-scale production. Your budgeting should account for these cost implications, balancing the need for detailed process data with the financial investment required at each stage.

Regulatory Considerations at Different Scales

Regulatory considerations differ significantly between R&D scale and pilot scale, with pilot scale requiring more stringent compliance to Good Manufacturing Practices (GMP) and adherence to regulatory filings such as Investigational New Drug (IND) applications. R&D scale activities often focus on preliminary safety and efficacy data under less stringent oversight, while pilot scale involves scaled-up production processes subject to rigorous validation protocols and quality control measures. Understanding these distinctions is critical for meeting FDA, EMA, and other global regulatory agency requirements during drug development and technology transfer stages.

Transitioning from R&D to Pilot Scale

Transitioning from R&D scale to pilot scale involves scaling up processes from laboratory experiments to small-scale production units, ensuring reproducibility and process stability. Critical parameters such as equipment configuration, material flow rates, and quality control measures must be optimized to reflect industrial conditions accurately. Successful scale-up minimizes risks by validating process scalability and identifying potential operational challenges before full-scale manufacturing.

R&D Scale vs Pilot Scale Infographic

libmatt.com

libmatt.com