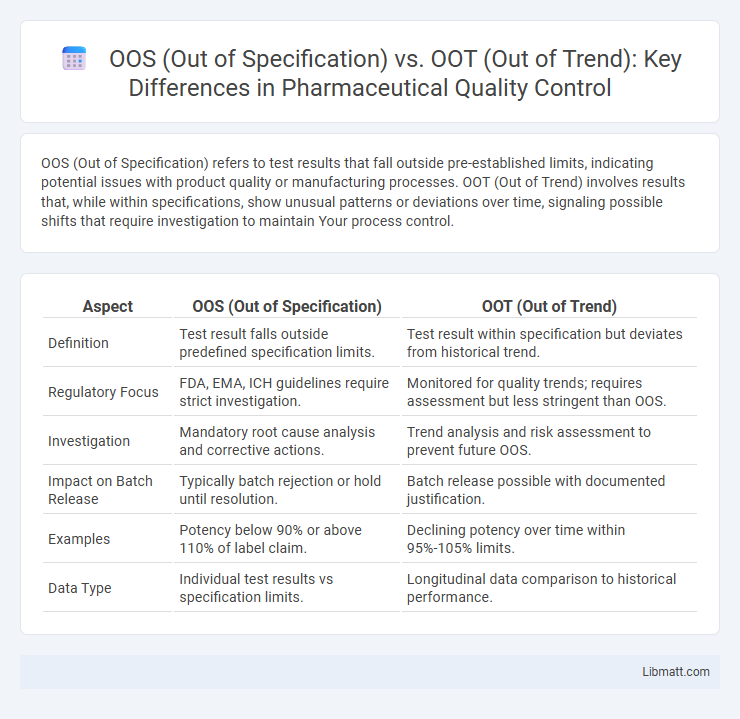

OOS (Out of Specification) refers to test results that fall outside pre-established limits, indicating potential issues with product quality or manufacturing processes. OOT (Out of Trend) involves results that, while within specifications, show unusual patterns or deviations over time, signaling possible shifts that require investigation to maintain Your process control.

Table of Comparison

| Aspect | OOS (Out of Specification) | OOT (Out of Trend) |

|---|---|---|

| Definition | Test result falls outside predefined specification limits. | Test result within specification but deviates from historical trend. |

| Regulatory Focus | FDA, EMA, ICH guidelines require strict investigation. | Monitored for quality trends; requires assessment but less stringent than OOS. |

| Investigation | Mandatory root cause analysis and corrective actions. | Trend analysis and risk assessment to prevent future OOS. |

| Impact on Batch Release | Typically batch rejection or hold until resolution. | Batch release possible with documented justification. |

| Examples | Potency below 90% or above 110% of label claim. | Declining potency over time within 95%-105% limits. |

| Data Type | Individual test results vs specification limits. | Longitudinal data comparison to historical performance. |

Understanding OOS (Out of Specification)

OOS (Out of Specification) refers to test results that fall outside the established acceptance criteria or regulatory limits, indicating a potential quality issue with the product or process. Understanding OOS involves identifying the root cause through thorough investigation, such as reviewing raw data, equipment calibration, and analyst performance to determine if the deviation is due to an error or an actual product failure. Your ability to accurately manage OOS results ensures compliance with regulatory standards and maintains product safety and efficacy.

Defining OOT (Out of Trend)

OOT (Out of Trend) refers to data points or results that deviate from an established historical trend or pattern within a defined timeframe, indicating potential process shifts or emerging issues that are not immediately out of specification. Unlike OOS (Out of Specification), which involves values outside predefined acceptance criteria, OOT highlights anomalies in data behavior while still remaining within specification limits. Identifying OOT helps in early detection of trends that might lead to future OOS events, enabling proactive quality control and process optimization.

Key Differences Between OOS and OOT

OOS (Out of Specification) refers to test results that fall outside predefined acceptance criteria, indicating a potential quality or compliance issue requiring investigation. OOT (Out of Trend) involves data points that deviate from established historical patterns or trends but still fall within specifications, signaling potential process shifts or emerging problems. The key differences lie in OOS triggering immediate corrective actions due to regulatory limits, while OOT focuses on monitoring and trend analysis to prevent future OOS occurrences.

Regulatory Requirements for OOS and OOT

Regulatory requirements for OOS (Out of Specification) results mandate immediate investigation and documented justification to ensure product quality and compliance with pharmacopeial standards such as those from the FDA, EMA, and ICH guidelines. OOT (Out of Trend) results require trend analysis over time, with regulatory bodies demanding robust procedures for monitoring, investigating, and addressing deviations that may indicate process variability or shift before product quality is compromised. Both OOS and OOT investigations must adhere to detailed protocols for root cause analysis, CAPA (Corrective and Preventive Actions), and comprehensive documentation to satisfy regulatory inspections and audits.

Causes and Impact of OOS Results

OOS (Out of Specification) results occur when a product fails to meet predefined quality criteria, often caused by manufacturing errors, equipment malfunction, or analytical method issues, leading to potential batch rejection and increased production costs. OOT (Out of Trend) results signal deviations from established data patterns without breaching specifications, typically due to subtle process variations or raw material inconsistencies, which may indicate a risk of future OOS events if unaddressed. Both OOS and OOT results impact product quality assurance, regulatory compliance, and corrective action strategies critical for maintaining pharmaceutical manufacturing integrity.

Identifying and Interpreting OOT Data

OOT (Out of Trend) data identifies results that deviate from established historical patterns without necessarily breaching defined specification limits, while OOS (Out of Specification) indicates test results falling outside predetermined acceptance criteria. Interpreting OOT involves statistical trend analysis and root cause investigation to determine if the variation signifies a potential quality issue requiring corrective action. Your analytical approach to OOT data ensures early detection of process shifts before yielding OOS outcomes, safeguarding product consistency and compliance.

Investigation Procedures for OOS Events

Investigation procedures for Out of Specification (OOS) events require immediate sample retesting and a thorough review of all test methods, equipment, and environmental conditions to identify potential errors or deviations. Out of Trend (OOT) investigations focus on analyzing historical data trends to detect gradual shifts in process performance, often involving statistical analysis and process history review rather than retesting. Your OOS investigations prioritize confirming result validity, while OOT procedures emphasize early detection of process inconsistencies to maintain product quality.

OOT Trending Analysis and Evaluation

OOT (Out of Trend) trending analysis involves monitoring data patterns over time to detect deviations from established trends even when individual results remain within specification limits. This evaluation uses statistical tools like control charts, regression analysis, and moving averages to identify subtle shifts in process performance or product quality. Proper OOT analysis enables early detection of process drifts, preventing potential failures before they lead to OOS (Out of Specification) results.

Preventive Measures for OOS and OOT

Preventive measures for OOS (Out of Specification) include stringent process controls, routine calibration of equipment, and thorough employee training to maintain product quality within defined specifications. For OOT (Out of Trend), continuous monitoring of data trends, trend analysis tools, and early detection systems help identify deviations before they impact product quality. Implementing these measures ensures Your production processes remain consistent and compliant with regulatory standards.

Best Practices for Managing OOS and OOT in Quality Systems

Effective management of OOS (Out of Specification) and OOT (Out of Trend) results in quality systems involves robust investigation protocols and thorough root cause analysis to ensure product compliance and process consistency. Integrating real-time monitoring with statistical process control (SPC) enhances early detection and differentiation between random variations and true deviations requiring corrective actions. Documentation and training aligned with regulatory guidelines such as FDA 21 CFR Part 211 support transparent reporting and continuous improvement in pharmaceutical quality management.

OOS (Out of Specification) vs OOT (Out of Trend) Infographic

libmatt.com

libmatt.com