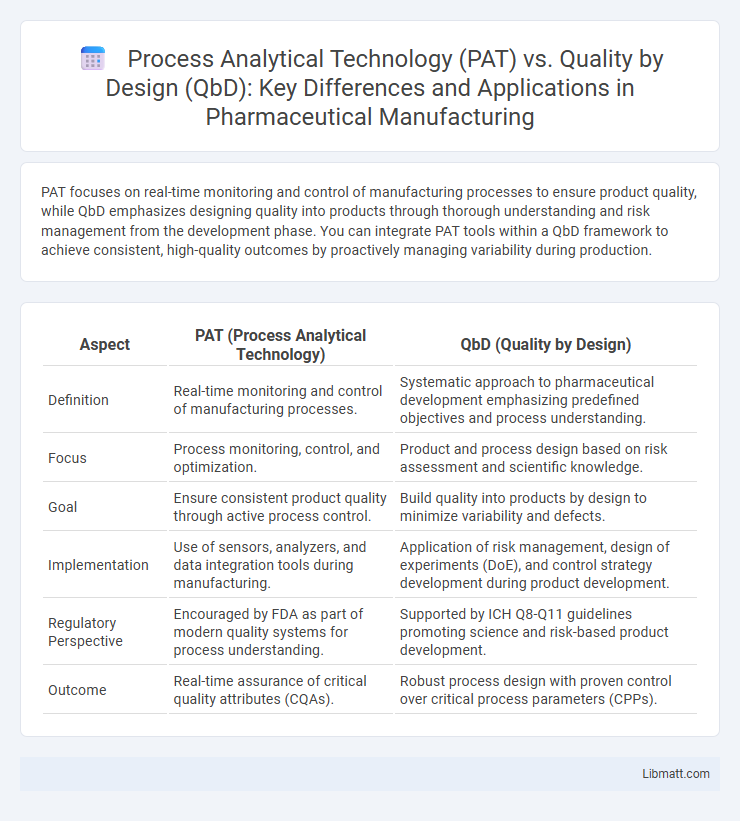

PAT focuses on real-time monitoring and control of manufacturing processes to ensure product quality, while QbD emphasizes designing quality into products through thorough understanding and risk management from the development phase. You can integrate PAT tools within a QbD framework to achieve consistent, high-quality outcomes by proactively managing variability during production.

Table of Comparison

| Aspect | PAT (Process Analytical Technology) | QbD (Quality by Design) |

|---|---|---|

| Definition | Real-time monitoring and control of manufacturing processes. | Systematic approach to pharmaceutical development emphasizing predefined objectives and process understanding. |

| Focus | Process monitoring, control, and optimization. | Product and process design based on risk assessment and scientific knowledge. |

| Goal | Ensure consistent product quality through active process control. | Build quality into products by design to minimize variability and defects. |

| Implementation | Use of sensors, analyzers, and data integration tools during manufacturing. | Application of risk management, design of experiments (DoE), and control strategy development during product development. |

| Regulatory Perspective | Encouraged by FDA as part of modern quality systems for process understanding. | Supported by ICH Q8-Q11 guidelines promoting science and risk-based product development. |

| Outcome | Real-time assurance of critical quality attributes (CQAs). | Robust process design with proven control over critical process parameters (CPPs). |

Understanding PAT: Definition and Core Principles

Process Analytical Technology (PAT) is a system for designing, analyzing, and controlling manufacturing processes through real-time measurements of critical quality and performance attributes. Core principles of PAT emphasize the use of advanced analytical tools, process analyzers, and feedback control mechanisms to ensure consistent product quality and optimize process efficiency. By enabling continuous monitoring and data-driven decision-making, PAT supports proactive quality assurance within pharmaceutical manufacturing.

QbD Explained: Key Concepts and Objectives

Quality by Design (QbD) is a systematic approach to pharmaceutical development that emphasizes understanding product and process variability to ensure quality. It involves defining a target product profile, identifying critical quality attributes (CQAs), and establishing control strategies to consistently meet desired quality standards. The primary objective of QbD is to build quality into the product from the outset, reducing reliance on end-product testing and enhancing regulatory compliance.

PAT vs QbD: Fundamental Differences

PAT (Process Analytical Technology) centers on real-time monitoring and control of manufacturing processes using advanced analytical tools, whereas QbD (Quality by Design) is a proactive framework that emphasizes designing quality into the product from the outset through systematic understanding and risk management. PAT acts as an enabling technology within the broader QbD approach, providing data and insights essential for maintaining consistent product quality. Your ability to integrate PAT into QbD strategies enhances process efficiency and ensures robust regulatory compliance.

Historical Development of PAT and QbD

Process Analytical Technology (PAT) emerged in the early 2000s as an FDA initiative to enhance pharmaceutical manufacturing through real-time monitoring and control of critical quality attributes, driven by advances in sensor and analytical technologies. Quality by Design (QbD), formalized by the FDA around the same period, originated from risk management and product design principles aiming to build quality into products from the earliest stages via a deep understanding of formulation and process variables. Both frameworks evolved synergistically, with QbD providing the systematic design foundation and PAT serving as the technological enabler for continuous process verification and improved regulatory compliance.

Regulatory Perspectives on PAT and QbD

Regulatory perspectives on Process Analytical Technology (PAT) and Quality by Design (QbD) emphasize their roles in enhancing pharmaceutical manufacturing quality and efficiency. PAT enables real-time monitoring and control of critical process parameters, aligning with regulatory expectations for continuous process verification and improved product consistency. QbD frameworks support regulatory submissions by providing structured risk assessments and design spaces, facilitating more flexible regulatory processes and post-approval changes.

Integrating PAT into QbD Frameworks

Integrating Process Analytical Technology (PAT) into Quality by Design (QbD) frameworks enhances real-time monitoring and control of manufacturing processes, ensuring consistent product quality and process understanding. PAT tools enable dynamic data collection and analysis, which supports critical quality attribute (CQA) identification and risk assessment central to QbD principles. Your pharmaceutical development benefits from this synergy by facilitating proactive decision-making and reducing variability throughout the product lifecycle.

Benefits of PAT in Pharmaceutical Manufacturing

Process Analytical Technology (PAT) enhances pharmaceutical manufacturing by enabling real-time monitoring and control of critical process parameters, leading to improved product quality and consistency. PAT reduces batch variability and shortens production times through continuous data collection and analysis, ensuring regulatory compliance and minimizing waste. Your manufacturing process benefits from increased efficiency, cost savings, and faster time-to-market by implementing PAT alongside Quality by Design principles.

QbD’s Impact on Product Consistency and Quality

Quality by Design (QbD) significantly enhances product consistency and quality by embedding risk management and robust control strategies throughout the pharmaceutical development process. Integrating QbD principles enables systematic identification of critical quality attributes (CQAs) and critical process parameters (CPPs), fostering improved process understanding and control. This structured approach ensures that variability is minimized, leading to reliable production of safe and efficacious products.

Challenges in Implementing PAT and QbD

Implementing Process Analytical Technology (PAT) and Quality by Design (QbD) presents notable challenges such as high initial costs, complexity of integrating real-time monitoring systems, and the need for extensive training and cultural change within organizations. Regulatory expectations require robust validation and continuous data analysis, increasing the demand for skilled personnel and advanced data management tools. Your success depends on overcoming resistance to change and investing in cross-functional collaboration to fully realize the benefits of PAT and QbD frameworks.

Future Trends: Harmonizing PAT and QbD in Pharma

Emerging trends in pharmaceutical manufacturing emphasize the integration of Process Analytical Technology (PAT) and Quality by Design (QbD) to achieve real-time quality assurance and enhanced process control. Leveraging advanced analytics, machine learning, and IoT-enabled sensors, this harmonization fosters continuous monitoring, reduces batch variability, and accelerates regulatory approval processes. Collaborative frameworks between regulators and industry stakeholders are driving standardized PAT-QbD implementations, ultimately supporting more robust, efficient, and patient-centric drug development pipelines.

PAT (Process Analytical Technology) vs QbD (Quality by Design) Infographic

libmatt.com

libmatt.com