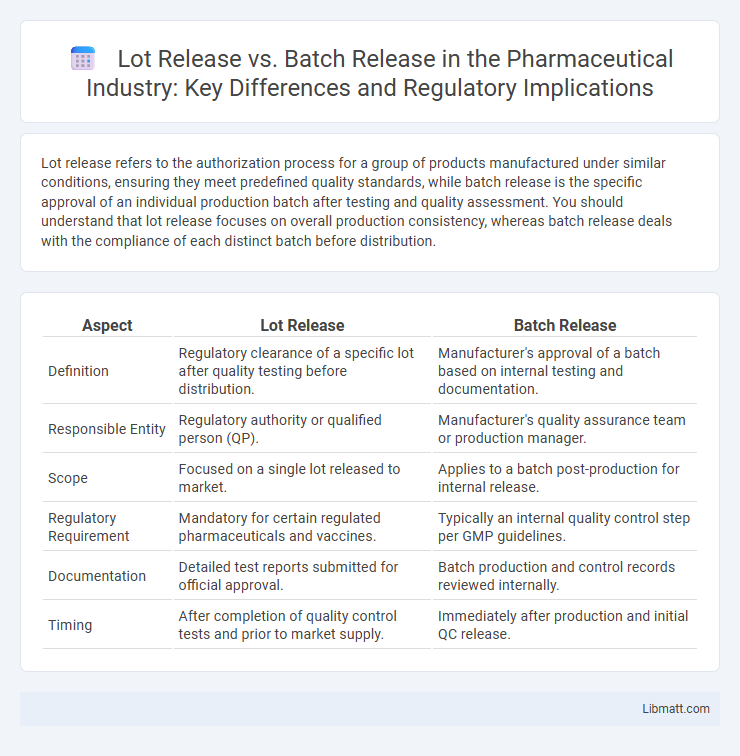

Lot release refers to the authorization process for a group of products manufactured under similar conditions, ensuring they meet predefined quality standards, while batch release is the specific approval of an individual production batch after testing and quality assessment. You should understand that lot release focuses on overall production consistency, whereas batch release deals with the compliance of each distinct batch before distribution.

Table of Comparison

| Aspect | Lot Release | Batch Release |

|---|---|---|

| Definition | Regulatory clearance of a specific lot after quality testing before distribution. | Manufacturer's approval of a batch based on internal testing and documentation. |

| Responsible Entity | Regulatory authority or qualified person (QP). | Manufacturer's quality assurance team or production manager. |

| Scope | Focused on a single lot released to market. | Applies to a batch post-production for internal release. |

| Regulatory Requirement | Mandatory for certain regulated pharmaceuticals and vaccines. | Typically an internal quality control step per GMP guidelines. |

| Documentation | Detailed test reports submitted for official approval. | Batch production and control records reviewed internally. |

| Timing | After completion of quality control tests and prior to market supply. | Immediately after production and initial QC release. |

Introduction to Lot Release and Batch Release

Lot release and batch release are quality control processes used in pharmaceutical and manufacturing industries to ensure product safety and compliance before distribution. Lot release involves a formal procedure, often regulated by health authorities, to evaluate and approve a specific lot of products by reviewing test results and documentation. Batch release refers to the internal verification performed by manufacturers to confirm that each batch meets predefined specifications and quality standards before it reaches you.

Key Definitions: Lot Release vs Batch Release

Lot release refers to the formal evaluation and approval process conducted by regulatory authorities to assess the quality and compliance of a specific manufactured lot before it is distributed to the market. Batch release involves the manufacturer's internal quality control procedures to verify that a production batch meets predefined specifications and regulatory standards prior to release. Both processes ensure product safety and efficacy, with lot release typically representing an external regulatory checkpoint beyond the manufacturer's batch release.

Regulatory Framework for Lot and Batch Release

Lot release and batch release processes are governed by stringent regulatory frameworks set by agencies such as the FDA, EMA, and WHO to ensure product quality, safety, and efficacy before market distribution. Lot release involves a comprehensive evaluation and official authorization of each manufactured unit or lot, often requiring detailed documentation and laboratory testing according to pharmacopeial standards. Batch release typically refers to the manufacturer's internal quality control steps to verify compliance with predefined specifications, supported by validated analytical methods and regulatory guidelines like GMP and ICH Q7.

Main Objectives of Lot and Batch Release

Lot release aims to ensure that a specific quantity of pharmaceutical products meets predefined quality, safety, and efficacy criteria before distribution, focusing on thorough evaluation of each individual lot. Batch release also verifies compliance with regulatory standards but emphasizes confirming consistent production processes across multiple batches to maintain overall product uniformity. Both processes are critical for safeguarding public health by preventing substandard or contaminated products from reaching the market.

Lot Release Process: Steps and Criteria

The lot release process involves a series of rigorous quality control steps, including sampling, testing for potency, purity, and safety, followed by documentation review to ensure compliance with regulatory standards. Batch release criteria focus on meeting predefined specifications for critical quality attributes such as identity, strength, and microbial limits to confirm the product's consistency and reliability. Your role in the lot release process ensures that only batches meeting all regulatory and quality benchmarks are authorized for distribution and use.

Batch Release Workflow: Procedures and Requirements

Batch release workflow involves a systematic series of procedures and requirements ensuring product quality and compliance before distribution. It includes thorough documentation review, quality control testing, and approval by authorized personnel to verify that each batch meets predefined specifications. Your role in overseeing traceability and adherence to regulatory standards is critical for a successful and compliant batch release process.

Critical Differences Between Lot and Batch Release

Lot release and batch release differ primarily in scope and traceability, with lot release referring to the approval of a specific quantity of product produced under uniform conditions, while batch release pertains to a subset within the lot, often used in pharmaceuticals or manufacturing for quality control. Critical differences include the level of documentation and testing required, where lot release demands comprehensive evaluation of the entire production run, whereas batch release may focus on smaller sample testing to ensure consistency. Understanding these distinctions ensures your quality assurance processes align with regulatory standards and operational requirements.

Quality Assurance in Lot and Batch Release

Quality assurance in lot release involves verifying the entire quantity of a product manufactured under uniform conditions, ensuring consistent compliance with predefined quality standards before distribution. Batch release focuses on quality control of specific production units, with detailed testing and documentation for each batch to guarantee product safety and efficacy. Your manufacturing process benefits from rigorous QA protocols in both lot and batch releases, minimizing risks of defects and regulatory non-compliance.

Common Challenges in Lot and Batch Release

Common challenges in lot release and batch release processes include ensuring consistent quality control, managing complex regulatory compliance, and maintaining accurate documentation. Variability in raw materials and production conditions can lead to delays or rejections during release, impacting your product's market availability. Efficient coordination between quality assurance teams and regulatory bodies is essential to mitigate risks and streamline the release workflow.

Best Practices for Effective Lot and Batch Release

Best practices for effective lot and batch release involve rigorous quality control measures, including thorough documentation and adherence to regulatory standards such as FDA and EMA guidelines. Implementing automated tracking systems and real-time data analytics enhances traceability and reduces errors during the release process. Your manufacturing operations benefit from cross-functional team reviews to ensure consistency, compliance, and timely release of products.

Lot release vs Batch release Infographic

libmatt.com

libmatt.com