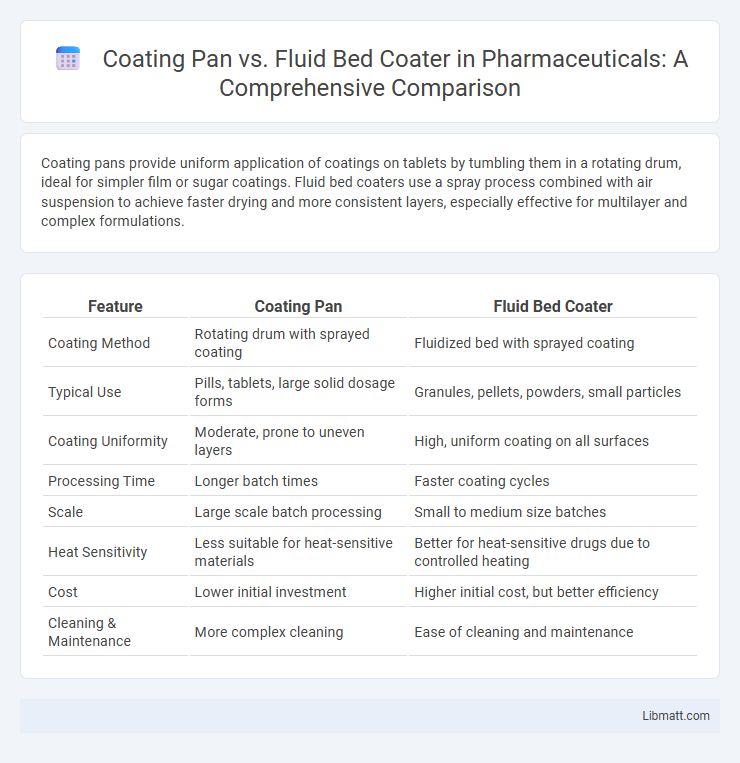

Coating pans provide uniform application of coatings on tablets by tumbling them in a rotating drum, ideal for simpler film or sugar coatings. Fluid bed coaters use a spray process combined with air suspension to achieve faster drying and more consistent layers, especially effective for multilayer and complex formulations.

Table of Comparison

| Feature | Coating Pan | Fluid Bed Coater |

|---|---|---|

| Coating Method | Rotating drum with sprayed coating | Fluidized bed with sprayed coating |

| Typical Use | Pills, tablets, large solid dosage forms | Granules, pellets, powders, small particles |

| Coating Uniformity | Moderate, prone to uneven layers | High, uniform coating on all surfaces |

| Processing Time | Longer batch times | Faster coating cycles |

| Scale | Large scale batch processing | Small to medium size batches |

| Heat Sensitivity | Less suitable for heat-sensitive materials | Better for heat-sensitive drugs due to controlled heating |

| Cost | Lower initial investment | Higher initial cost, but better efficiency |

| Cleaning & Maintenance | More complex cleaning | Ease of cleaning and maintenance |

Introduction to Pharmaceutical Coating Technologies

Coating pan and fluid bed coater are essential pharmaceutical coating technologies used to enhance drug stability, control release, and mask taste. Coating pans utilize a rotating drum to apply thin liquid films uniformly on tablets, while fluid bed coaters suspend particles in a fast-moving air stream, enabling more efficient and even coating. Your choice depends on factors like coating material, tablet size, and desired production speed, ensuring optimal drug performance and patient compliance.

What is a Coating Pan?

A coating pan is a traditional pharmaceutical equipment used for applying uniform film or sugar coatings to tablets by rotating them in a tilted, circular drum. This process enhances tablet appearance, masks taste, and controls drug release through controlled layering. Your choice between a coating pan and fluid bed coater depends on desired coating uniformity, batch size, and moisture sensitivity of the material.

What is a Fluid Bed Coater?

A Fluid Bed Coater is a pharmaceutical equipment designed for coating particles, granules, or tablets by suspending them in a stream of air and applying coating material evenly on their surface. This process enhances drug stability, taste masking, and controlled release properties. Compared to a Coating Pan, the Fluid Bed Coater offers better uniformity and faster drying times, making it ideal for precision coating in pharmaceutical manufacturing.

Key Differences Between Coating Pan and Fluid Bed Coater

Coating pans use a rotating drum to apply liquid or powder coatings onto tablets, offering uniform layering ideal for large-scale production. Fluid bed coaters suspend tablets in an upward air stream, allowing for efficient drying and coating of irregularly shaped or heat-sensitive products. Key differences include the coating mechanism--rotating drum versus airborne suspension--and their suitability for different tablet characteristics and production scales.

Advantages of Using Coating Pan

Coating pans offer significant advantages such as uniform film application and high production capacity, making them ideal for large-scale pharmaceutical manufacturing. Their ability to handle a wide variety of tablet sizes and shapes with consistent quality improves efficiency and reduces material waste. Moreover, coating pans provide cost-effective operation and simple maintenance compared to more complex fluid bed coaters.

Benefits of Fluid Bed Coater Technology

Fluid bed coater technology offers superior uniformity in coating thickness and enhanced control over particle drying and cooling processes, resulting in higher product quality compared to traditional coating pans. This technology improves efficiency by reducing coating time and minimizing solvent use, making it an environmentally friendly and cost-effective choice. Your production can achieve better scalability and consistent batch-to-batch results with the advanced fluid bed coater system.

Limitations and Challenges: Coating Pan vs Fluid Bed Coater

Coating pans often face challenges with uniformity and batch size limitations, making consistent layer thickness difficult to achieve, especially for highly sensitive or irregularly shaped tablets. Fluid bed coaters offer better control over coating uniformity and efficiency but can be limited by higher operational costs and complexity in processing fine particles due to fluidization issues. Understanding these limitations helps you choose the optimal coating technology tailored to your formulation and production scale.

Application Areas for Each Coating Method

Coating pans are commonly used in pharmaceutical tablets, confectionery, and nuts to apply sugar or film coatings, suitable for larger batches with simpler coating requirements. Fluid bed coaters excel in uniform application of coatings on granules, pellets, and powders, widely utilized in pharmaceuticals for controlled-release formulations and in food industries for flavor encapsulation. Your choice depends on the product type and desired coating characteristics, with coating pans favoring solid tablet surfaces and fluid bed coaters providing consistent layers on particulate materials.

Factors to Consider When Choosing Between Coating Pan and Fluid Bed Coater

When choosing between a coating pan and a fluid bed coater, factors such as product type, batch size, and coating uniformity requirements play critical roles in decision-making. Coating pans are ideal for tablets needing thicker, uniform film coatings and handle larger batch sizes efficiently, while fluid bed coaters excel in coating particles and granules with superior drying and uniformity control. Consideration of processing time, scalability, and equipment cost is essential to optimize manufacturing efficiency and product quality.

Future Trends in Pharmaceutical Coating Technologies

Emerging pharmaceutical coating technologies emphasize automation, real-time monitoring, and precision in drug delivery, with coating pans evolving to integrate advanced process analytical technology (PAT) for enhanced film uniformity and efficiency. Fluid bed coaters are incorporating continuous processing and nanoparticle coatings to improve bioavailability and reduce production time. Both technologies are poised to adopt environmentally sustainable practices, including solvent-free and low-energy coating methods, aligning with regulatory trends and industry demands for greener manufacturing.

Coating Pan vs Fluid Bed Coater Infographic

libmatt.com

libmatt.com