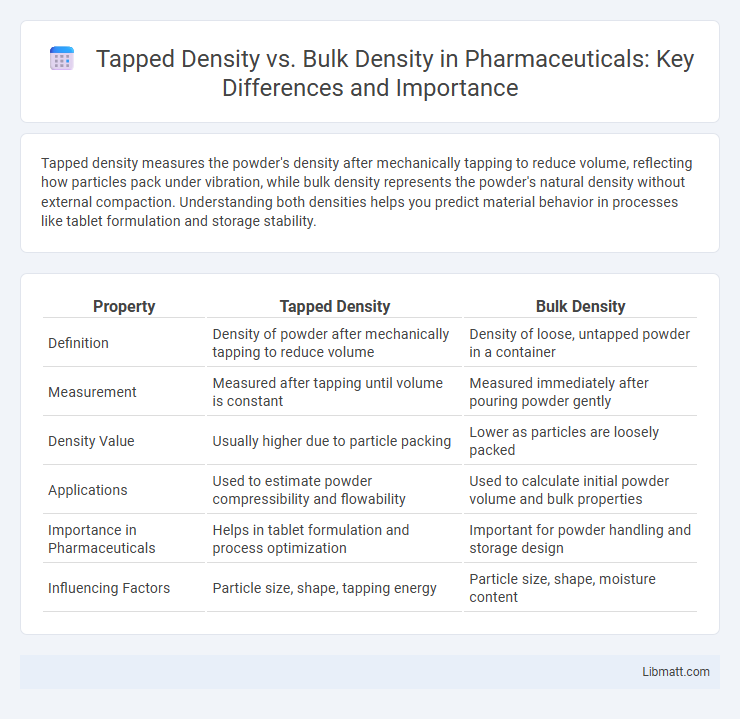

Tapped density measures the powder's density after mechanically tapping to reduce volume, reflecting how particles pack under vibration, while bulk density represents the powder's natural density without external compaction. Understanding both densities helps you predict material behavior in processes like tablet formulation and storage stability.

Table of Comparison

| Property | Tapped Density | Bulk Density |

|---|---|---|

| Definition | Density of powder after mechanically tapping to reduce volume | Density of loose, untapped powder in a container |

| Measurement | Measured after tapping until volume is constant | Measured immediately after pouring powder gently |

| Density Value | Usually higher due to particle packing | Lower as particles are loosely packed |

| Applications | Used to estimate powder compressibility and flowability | Used to calculate initial powder volume and bulk properties |

| Importance in Pharmaceuticals | Helps in tablet formulation and process optimization | Important for powder handling and storage design |

| Influencing Factors | Particle size, shape, tapping energy | Particle size, shape, moisture content |

Introduction to Tapped Density and Bulk Density

Tapped density measures the density of a powder after it has been compacted by tapping or vibration, reflecting how particles settle into a more tightly packed state. Bulk density represents the mass of powder per unit volume, including the spaces between particles when loosely packed. Understanding these densities helps you optimize material handling, packaging, and formulation processes in industries like pharmaceuticals and materials engineering.

Definition of Bulk Density

Bulk density is the mass of a powder or granulated material divided by the total volume it occupies, including the spaces between particles. This measurement reflects how a material settles naturally without compaction, providing insight into its storage and handling characteristics. Understanding bulk density helps you predict the material's flowability and packing efficiency in various industrial applications.

Definition of Tapped Density

Tapped density is the measure of a powder's density after it has been compacted or settled by tapping or vibration, reflecting how particles pack under external forces. It differs from bulk density, which represents the powder's volume without any external compression, including the void spaces between particles. Understanding your material's tapped density helps optimize packing, storage, and processing efficiency in various industrial applications.

Key Differences Between Tapped and Bulk Density

Tapped density measures the mass of powder settled into a volume after mechanical tapping, reflecting particle packing efficiency, whereas bulk density calculates the mass of powder in its loose, untapped state, indicating initial volume occupancy. Tapped density is typically higher than bulk density due to reduced void spaces, critical for applications in powder flowability and compaction processes. The difference between tapped and bulk density aids in determining the powder's compressibility index and Hausner ratio, essential parameters in pharmaceutical and material sciences for quality control and formulation development.

Importance in Pharmaceutical and Powder Industries

Tapped density and bulk density are critical parameters in the pharmaceutical and powder industries for assessing powder quality, flowability, and compaction characteristics. Tapped density measures the powder's volume after mechanical tapping, reflecting particle packing efficiency, while bulk density represents the powder volume in a loose state. Accurate determination of these densities ensures optimal formulation, enhances tablet uniformity, and improves processing efficiency in manufacturing.

Methods for Measuring Bulk Density

Bulk density is typically measured by gently pouring a powder into a graduated cylinder and recording the volume before calculating density as mass divided by volume. A more precise method involves using a tapped density tester, where the cylinder is mechanically tapped to compact the powder and reduce void spaces, providing the tapped density value. Understanding these measurement methods helps you accurately characterize material properties critical in industries like pharmaceuticals and materials science.

Methods for Measuring Tapped Density

Tapped density is measured by placing a powder sample in a graduated cylinder and mechanically tapping it a specified number of times, often between 500 to 1250 taps, to compact the particles and reduce the volume. You determine the tapped density by dividing the powder's mass by the volume after tapping, which is achieved using standardized tapping apparatus such as a tapped density tester or a mechanical tapping machine. This method provides crucial data for understanding powder flow properties, compaction, and packaging requirements.

Factors Influencing Density Measurements

Tapped density and bulk density measurements are influenced by factors such as particle size, shape, and moisture content, which affect powder packing and flow characteristics. The compaction method, including the intensity and number of taps or shakes during measurement, significantly alters tapped density by reducing inter-particle voids. Environmental conditions like humidity and temperature can also impact density values by causing particle agglomeration or expansion.

Applications of Density Data in Formulation

Tapped density and bulk density are critical parameters in pharmaceutical formulation, affecting tablet compressibility and flowability during manufacturing. Accurate density measurements guide formulation scientists in optimizing excipient selection and powder blending to ensure uniformity and stability of your final product. These density data enable predictions of packing behavior and aerosol performance, especially in dry powder inhalers and compressed tablet formulations.

Conclusion: Choosing Between Tapped and Bulk Density

Tapped density measures the powder's density after compaction through tapping, reflecting how particles settle and pack tightly. Bulk density represents the loose powder's mass per unit volume, including void spaces between particles. Your choice between tapped and bulk density depends on the application: use bulk density for handling and storage considerations, while tapped density is better for processes requiring powder flowability and compaction characteristics.

Tapped density vs bulk density Infographic

libmatt.com

libmatt.com