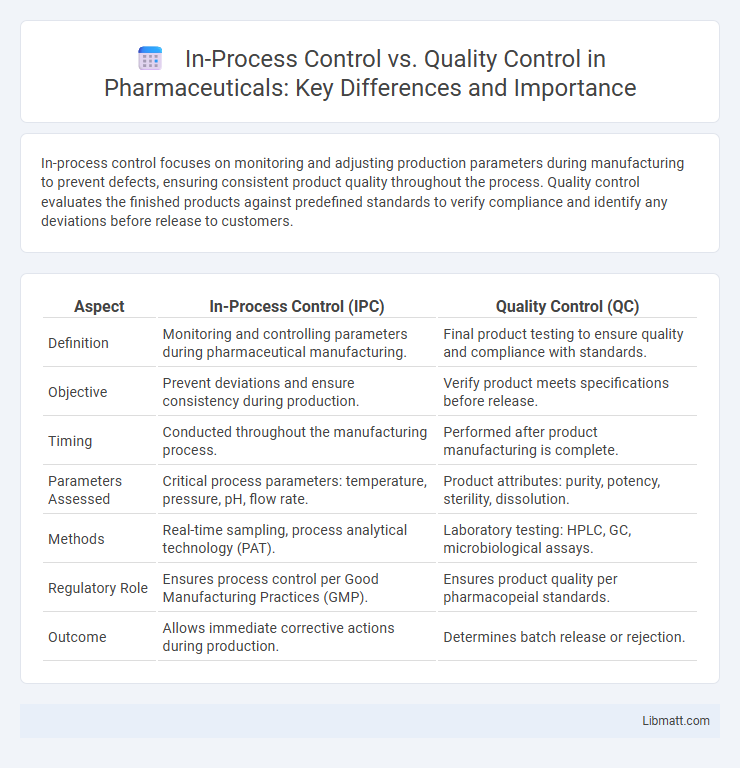

In-process control focuses on monitoring and adjusting production parameters during manufacturing to prevent defects, ensuring consistent product quality throughout the process. Quality control evaluates the finished products against predefined standards to verify compliance and identify any deviations before release to customers.

Table of Comparison

| Aspect | In-Process Control (IPC) | Quality Control (QC) |

|---|---|---|

| Definition | Monitoring and controlling parameters during pharmaceutical manufacturing. | Final product testing to ensure quality and compliance with standards. |

| Objective | Prevent deviations and ensure consistency during production. | Verify product meets specifications before release. |

| Timing | Conducted throughout the manufacturing process. | Performed after product manufacturing is complete. |

| Parameters Assessed | Critical process parameters: temperature, pressure, pH, flow rate. | Product attributes: purity, potency, sterility, dissolution. |

| Methods | Real-time sampling, process analytical technology (PAT). | Laboratory testing: HPLC, GC, microbiological assays. |

| Regulatory Role | Ensures process control per Good Manufacturing Practices (GMP). | Ensures product quality per pharmacopeial standards. |

| Outcome | Allows immediate corrective actions during production. | Determines batch release or rejection. |

Introduction to In-Process Control and Quality Control

In-Process Control (IPC) involves real-time monitoring and adjustment during manufacturing to ensure each production step meets predefined specifications, reducing defects and enhancing efficiency. Quality Control (QC) focuses on the inspection and testing of final products to verify compliance with quality standards before delivery. Your understanding of IPC and QC helps optimize production processes and maintain high product quality.

Defining In-Process Control (IPC)

In-Process Control (IPC) involves continuous monitoring and testing during the manufacturing process to ensure product quality and detect deviations early. IPC focuses on measuring critical parameters such as temperature, pressure, and dimensions in real time to maintain consistency and prevent defects. This proactive approach contrasts with Quality Control, which typically involves final product inspection and testing after production is completed.

What is Quality Control (QC)?

Quality Control (QC) is a systematic process that ensures products meet predefined standards by inspecting and testing finished goods for defects and deviations. It involves procedures such as sampling, measurement, and visual inspections to verify compliance with quality specifications. QC helps prevent defective products from reaching customers, maintaining brand reputation and regulatory compliance.

Key Differences Between IPC and QC

In-Process Control (IPC) involves monitoring and controlling manufacturing processes in real-time to ensure product specifications are met, focusing on preventing defects during production. Quality Control (QC) emphasizes the inspection and testing of finished goods to identify and eliminate defects prior to shipment. IPC plays a proactive role in maintaining process stability, while QC serves as a reactive measure to verify product quality after production.

Purpose and Importance of In-Process Control

In-Process Control (IPC) serves as a critical mechanism to monitor and regulate manufacturing processes in real-time, ensuring product quality and consistency during production. Its purpose is to detect deviations early, allowing immediate corrective actions and minimizing defects, waste, and rework. This proactive approach is vital for maintaining compliance with industry standards such as GMP and ISO, ultimately safeguarding consumer safety and optimizing production efficiency.

Role of Quality Control in Product Assurance

Quality Control (QC) plays a critical role in product assurance by systematically verifying that products meet specified standards and regulatory requirements before they reach customers. QC involves rigorous testing, inspection, and validation processes to detect defects and ensure consistency in product quality throughout manufacturing. This proactive monitoring helps prevent faulty products from advancing in the production line, thereby safeguarding consumer safety and maintaining brand reputation.

Methods and Tools for In-Process Control

In-Process Control utilizes real-time monitoring methods such as Statistical Process Control (SPC), control charts, and automated sensor technologies to detect deviations during manufacturing. Tools like inline inspection systems, vision inspection machines, and process analyzers enable immediate adjustments to maintain product specifications. This proactive approach contrasts with post-production Quality Control, which focuses on final product inspection and defect identification.

Techniques and Standards in Quality Control

In quality control, techniques such as Statistical Process Control (SPC), Six Sigma, and ISO 9001 standards ensure consistent product quality by monitoring production variables and minimizing defects. In-process control incorporates real-time inspections and automated sensors to detect deviations during manufacturing, enabling immediate adjustments to maintain compliance with set quality criteria. Adherence to established standards like ISO 9001 and industry-specific regulations guarantees that quality control processes meet rigorous benchmarks for reliability and safety.

Impact of IPC and QC on Manufacturing Outcomes

In-Process Control (IPC) and Quality Control (QC) both play critical roles in enhancing manufacturing outcomes by ensuring product consistency and reducing defects. IPC monitors and adjusts processes in real-time to prevent errors, leading to improved efficiency and lower production costs. QC verifies the final products meet specifications, ensuring customer satisfaction and regulatory compliance.

Best Practices for Integrating IPC and QC

Integrating In-Process Control (IPC) and Quality Control (QC) optimizes manufacturing efficiency by ensuring continuous monitoring and verification throughout production stages. Best practices emphasize real-time data sharing between IPC and QC systems, enabling early detection of deviations and minimizing waste. Your quality management improves significantly when predictive analytics link IPC measurements to QC standards, fostering proactive adjustments and compliance.

In-Process Control vs Quality Control Infographic

libmatt.com

libmatt.com