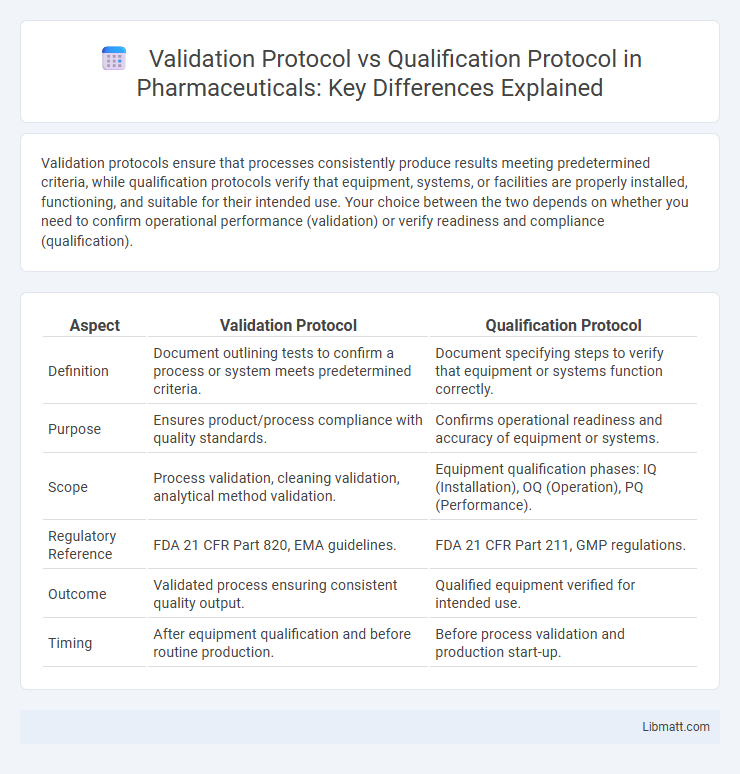

Validation protocols ensure that processes consistently produce results meeting predetermined criteria, while qualification protocols verify that equipment, systems, or facilities are properly installed, functioning, and suitable for their intended use. Your choice between the two depends on whether you need to confirm operational performance (validation) or verify readiness and compliance (qualification).

Table of Comparison

| Aspect | Validation Protocol | Qualification Protocol |

|---|---|---|

| Definition | Document outlining tests to confirm a process or system meets predetermined criteria. | Document specifying steps to verify that equipment or systems function correctly. |

| Purpose | Ensures product/process compliance with quality standards. | Confirms operational readiness and accuracy of equipment or systems. |

| Scope | Process validation, cleaning validation, analytical method validation. | Equipment qualification phases: IQ (Installation), OQ (Operation), PQ (Performance). |

| Regulatory Reference | FDA 21 CFR Part 820, EMA guidelines. | FDA 21 CFR Part 211, GMP regulations. |

| Outcome | Validated process ensuring consistent quality output. | Qualified equipment verified for intended use. |

| Timing | After equipment qualification and before routine production. | Before process validation and production start-up. |

Introduction to Validation and Qualification Protocols

Validation protocols establish systematic procedures to confirm that a process, system, or equipment meets predetermined specifications and consistently produces desired results. Qualification protocols focus specifically on verifying and documenting that equipment or systems are installed, operated, and perform according to established criteria. Your understanding of both ensures compliance with regulatory standards and enhances quality assurance in manufacturing or laboratory environments.

Definitions: Validation Protocol vs Qualification Protocol

A Validation Protocol is a detailed plan that outlines the procedures, acceptance criteria, and responsibilities for confirming that a process, system, or equipment consistently produces results meeting predetermined specifications. A Qualification Protocol specifically focuses on verifying that individual pieces of equipment or systems meet their design and installation requirements before being used in production. Your understanding of these protocols ensures compliance with regulatory standards and supports effective quality management in manufacturing environments.

Purpose and Objectives of Each Protocol

Validation protocols ensure that systems and processes consistently produce results meeting predetermined specifications, focusing on demonstrating overall compliance and reliability. Qualification protocols target specific equipment or components, verifying their proper installation, operation, and performance according to predefined criteria. Both protocols aim to maintain quality and regulatory adherence, with validation addressing system-level assurance and qualification emphasizing individual elements.

Key Components of a Validation Protocol

Key components of a validation protocol include a detailed scope, objectives, and acceptance criteria that ensure processes meet regulatory standards. It outlines specific test procedures, responsibilities, and documentation requirements to verify system functionality and performance. Your validation protocol establishes a clear framework to confirm that equipment or software consistently produces reliable and compliant results.

Key Components of a Qualification Protocol

Key components of a qualification protocol include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to ensure equipment and systems meet pre-defined criteria. Documentation of acceptance criteria, test procedures, and detailed protocols provides evidence of compliance and system readiness. Your quality assurance depends on thoroughly executing each phase to validate consistent and reliable performance.

Similarities Between Validation and Qualification Protocols

Validation and qualification protocols both serve to ensure systems and equipment meet predetermined criteria through systematic testing and documentation. Each protocol emphasizes reproducibility, accuracy, and compliance with industry standards to guarantee consistent performance. They require detailed test plans, acceptance criteria, and traceability to regulatory guidelines such as FDA 21 CFR Part 11 or ISO 9001.

Differences Between Validation and Qualification Protocols

Validation protocols define the systematic process of demonstrating that a system or process consistently produces results meeting predetermined criteria, while qualification protocols specifically verify and document that equipment or components operate according to specified requirements. Differences between validation and qualification protocols lie in their scope and purpose; validation covers overall system performance and product quality, whereas qualification focuses on proving that individual equipment or systems are installed, operate, and perform as intended. Validation protocols typically include IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification), while qualification protocols concentrate primarily on IQ and OQ stages.

Regulatory Guidelines and Industry Standards

Validation protocols align with regulatory guidelines such as FDA's 21 CFR Part 11 and EMA's GxP standards, ensuring processes meet predefined acceptance criteria to guarantee product quality and compliance. Qualification protocols focus on equipment and facility qualification as per industry standards like ISPE's Good Practice Guides and USP <1058>, confirming that systems consistently operate within specified limits. Both protocols are critical components of a compliant quality management system, supporting regulatory submissions and audits.

Common Challenges in Implementing Protocols

Validation protocols and qualification protocols often face challenges such as unclear acceptance criteria, insufficient documentation, and lack of stakeholder alignment, which can lead to execution delays and non-compliance risks. Incomplete risk assessments and inadequate training on protocol requirements further complicate adherence and accuracy in test results. Addressing these issues requires rigorous planning, continuous communication, and thorough review processes to ensure regulatory standards and operational efficiency are met.

Best Practices for Protocol Development and Execution

Validation protocols establish standardized procedures to ensure a system or process meets predetermined requirements, while qualification protocols verify specific equipment or components perform correctly within defined limits. Best practices for protocol development include clear objectives, detailed acceptance criteria, comprehensive test plans, and thorough documentation to provide traceability and reproducibility. Execution requires adherence to predefined steps, real-time data recording, deviation management, and formal review to guarantee reliability and regulatory compliance.

Validation protocol vs Qualification protocol Infographic

libmatt.com

libmatt.com