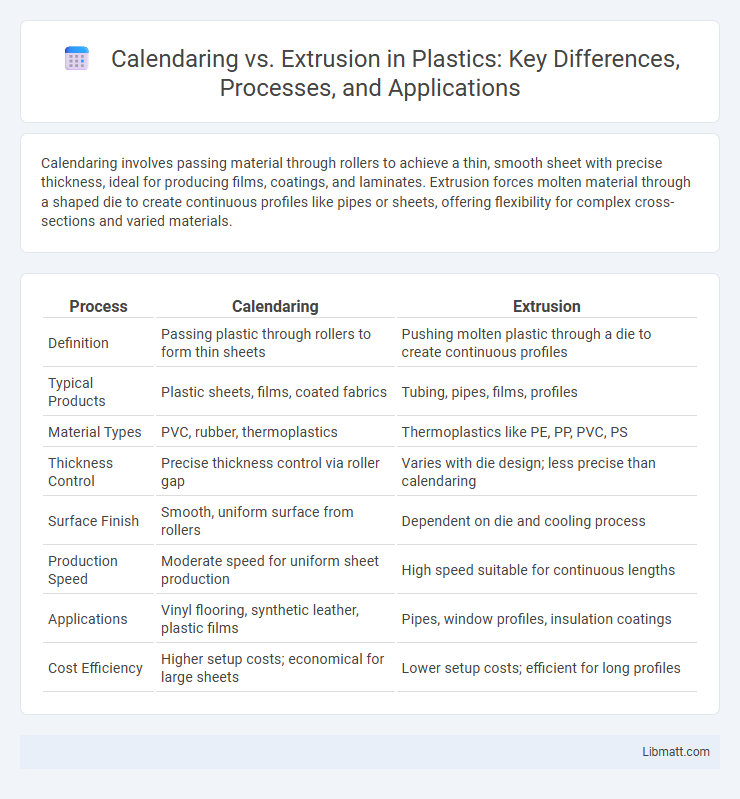

Calendaring involves passing material through rollers to achieve a thin, smooth sheet with precise thickness, ideal for producing films, coatings, and laminates. Extrusion forces molten material through a shaped die to create continuous profiles like pipes or sheets, offering flexibility for complex cross-sections and varied materials.

Table of Comparison

| Process | Calendaring | Extrusion |

|---|---|---|

| Definition | Passing plastic through rollers to form thin sheets | Pushing molten plastic through a die to create continuous profiles |

| Typical Products | Plastic sheets, films, coated fabrics | Tubing, pipes, films, profiles |

| Material Types | PVC, rubber, thermoplastics | Thermoplastics like PE, PP, PVC, PS |

| Thickness Control | Precise thickness control via roller gap | Varies with die design; less precise than calendaring |

| Surface Finish | Smooth, uniform surface from rollers | Dependent on die and cooling process |

| Production Speed | Moderate speed for uniform sheet production | High speed suitable for continuous lengths |

| Applications | Vinyl flooring, synthetic leather, plastic films | Pipes, window profiles, insulation coatings |

| Cost Efficiency | Higher setup costs; economical for large sheets | Lower setup costs; efficient for long profiles |

Introduction to Calendaring and Extrusion

Calendaring is a manufacturing process where material is passed through rollers to achieve a uniform thickness and smooth surface, commonly used in the production of rubber, plastics, and textiles. Extrusion involves forcing material through a shaped die to create continuous profiles with a fixed cross-section, widely utilized for producing pipes, sheets, and films. Both techniques are essential in polymer processing, with calendaring emphasizing surface finish and thickness control, while extrusion focuses on shaping complex geometries.

Understanding the Calendaring Process

The calendaring process involves passing material, such as rubber or plastic, through a series of rollers to create sheets of uniform thickness and smooth surface texture. This technique allows precise control over the material's thickness and finish, making it ideal for producing films, coatings, and laminates. Understanding calendaring helps you optimize production efficiency and achieve consistent product quality compared to extrusion, which involves shaping material by forcing it through a die.

Key Steps in Extrusion Technology

Extrusion technology involves key steps such as feeding raw plastic pellets into the hopper, melting and homogenizing the material within the heated barrel, and forcing the molten polymer through a shaped die to form continuous profiles. Cooling the extruded product using water baths or air is crucial to solidify and maintain dimensional stability. You can optimize production efficiency by carefully controlling processing parameters like temperature, screw speed, and die design.

Materials Suitable for Calendaring

Materials suitable for calendaring include thermoplastics such as polyvinyl chloride (PVC), rubber compounds, and certain types of polyethylene and polyurethane. These materials must have appropriate viscosity and elasticity to withstand the pressure and shear forces during the calendaring process while achieving uniform thickness and smooth surface finish. Your choice of material significantly impacts the quality and performance of the final calendared product compared to extrusion.

Materials Compatible with Extrusion

Extrusion is compatible with a wide range of materials including thermoplastics like polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC), as well as thermosetting plastics and some metal alloys. The process allows for continuous shaping of materials with specific thermal and flow properties, which must withstand high temperatures and pressures without degradation. Unlike calendaring, which typically handles softer, more flexible polymers such as PVC and rubber, extrusion is suitable for materials requiring precise control over thickness and cross-sectional profiles.

Comparative Advantages: Calendaring vs Extrusion

Calendaring offers superior surface finish and precise thickness control, making it ideal for producing thin, uniform sheets used in applications like laminates and plastic films. Extrusion excels in creating complex continuous profiles and hollow shapes with high production rates, suitable for pipe manufacturing and insulation materials. Your choice depends on whether you prioritize surface quality and dimensional accuracy (calendaring) or versatile shaping and efficient material flow (extrusion).

Applications and End-Uses of Calendared Products

Calendared products find extensive applications in industries such as automotive interiors, packaging films, wallpapers, and synthetic leather due to their smooth, glossy surfaces and precise thickness control. These materials are valued for decorative laminates, conveyor belts, and floor coverings, where uniformity and aesthetic appeal are critical. Unlike extrusion, calendaring excels in producing thin, continuous sheets ideal for high-quality surface finishes and specialized end-uses in textiles and coated fabrics.

Common Applications of Extruded Products

Extruded products are widely used in automotive manufacturing for components like bumpers and moldings, providing lightweight strength and design flexibility. In construction, extrusions serve as window frames, door profiles, and structural supports, enhancing durability and thermal efficiency. Consumer goods such as furniture and sports equipment also rely on extrusion for customized shapes and improved material performance.

Quality Control in Calendaring and Extrusion

Quality control in calendaring ensures consistent thickness, surface finish, and material density by precisely controlling nip pressure, temperature, and roll speed, minimizing defects and waviness in sheets or films. Extrusion quality control concentrates on uniform melt flow, temperature regulation, and die design to prevent issues like die lines, bubbles, and thickness variations in tubes, pipes, or profiles. Understanding how each process manages critical parameters helps you optimize product performance and reduce material waste.

Choosing Between Calendaring and Extrusion

Selecting between calendaring and extrusion depends on the desired material properties and product application; calendaring produces smooth, thin sheets with precise thickness control ideal for films and coatings, while extrusion creates complex cross-sectional shapes and solid profiles suitable for pipes, tubes, and structural components. Extrusion offers continuous production and versatility in shaping thermoplastics, whereas calendaring excels in surface finish and uniformity for flexible materials like PVC and rubber. Consider processing speed, material compatibility, and final product requirements to determine the most efficient and cost-effective method.

Calendaring vs extrusion Infographic

libmatt.com

libmatt.com