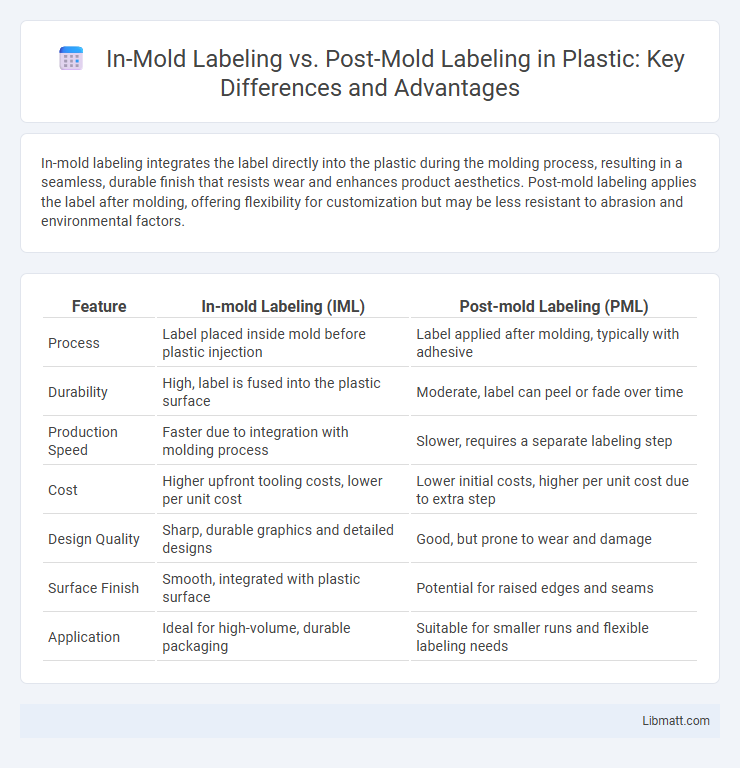

In-mold labeling integrates the label directly into the plastic during the molding process, resulting in a seamless, durable finish that resists wear and enhances product aesthetics. Post-mold labeling applies the label after molding, offering flexibility for customization but may be less resistant to abrasion and environmental factors.

Table of Comparison

| Feature | In-mold Labeling (IML) | Post-mold Labeling (PML) |

|---|---|---|

| Process | Label placed inside mold before plastic injection | Label applied after molding, typically with adhesive |

| Durability | High, label is fused into the plastic surface | Moderate, label can peel or fade over time |

| Production Speed | Faster due to integration with molding process | Slower, requires a separate labeling step |

| Cost | Higher upfront tooling costs, lower per unit cost | Lower initial costs, higher per unit cost due to extra step |

| Design Quality | Sharp, durable graphics and detailed designs | Good, but prone to wear and damage |

| Surface Finish | Smooth, integrated with plastic surface | Potential for raised edges and seams |

| Application | Ideal for high-volume, durable packaging | Suitable for smaller runs and flexible labeling needs |

Introduction to In-mold Labeling and Post-mold Labeling

In-mold labeling (IML) integrates the label into the plastic part during the molding process, creating a durable, seamless finish ideal for high-quality branding and product identification. Post-mold labeling involves applying labels after the molding process, offering flexibility in design changes and easier customization for small production runs. Your choice between IML and post-mold labeling depends on factors like production volume, durability requirements, and aesthetic preferences.

Defining In-mold Labeling (IML)

In-mold labeling (IML) integrates labels directly into the plastic molding process by placing pre-printed films or labels inside the mold before injecting molten plastic, creating a fused, durable decoration on the product surface. This method enhances resistance to wear, chemicals, and moisture compared to traditional post-mold labeling, which applies labels after molding through adhesive or heat transfer techniques. IML is widely used in packaging industries such as food containers and automotive parts due to its efficiency, superior print quality, and environmental benefits by reducing secondary processes and material waste.

Understanding Post-mold Labeling Processes

Post-mold labeling involves applying labels onto plastic products after the molding process, allowing for greater flexibility in design changes and label placement. This method supports various labeling techniques such as screen printing, hot stamping, or pressure-sensitive adhesives, ensuring durable and high-quality finishes tailored to your product needs. Understanding post-mold labeling processes helps optimize production efficiency and enhances visual appeal without altering the molded part itself.

Key Differences Between IML and Post-mold Labeling

In-mold labeling (IML) embeds labels directly into the plastic during the molding process, creating a seamless, durable, and high-quality finish resistant to scratches and chemicals. Post-mold labeling applies labels after molding, often involving adhesives that can degrade over time and may be less resistant to wear. Your choice between IML and post-mold labeling depends on factors like production speed, label durability requirements, and cost efficiency.

Material Compatibility and Label Durability

In-mold labeling ensures superior material compatibility by integrating labels directly into the mold during the plastic forming process, resulting in labels that are chemically bonded and highly resistant to wear, moisture, and chemicals. Post-mold labeling, applied after the molding process, may face adhesion challenges depending on the substrate and labeling materials, potentially reducing label durability under harsh environmental conditions. Choosing in-mold labeling enhances your product's longevity and visual appeal by providing labels that withstand abrasion and environmental exposure better than post-mold options.

Production Efficiency and Cost Comparison

In-mold labeling integrates the label directly into the molding process, significantly reducing production time and labor costs compared to post-mold labeling, which requires additional handling and adhesive application. This method minimizes material waste and enhances automation capabilities, leading to higher throughput and consistent quality. While initial tooling costs for in-mold labeling are higher, the overall cost per unit decreases with large production volumes, making it more cost-efficient than post-mold labeling in mass manufacturing.

Design Flexibility and Aesthetic Outcomes

In-mold labeling offers superior design flexibility by allowing complex, multi-color graphics and textured finishes to be directly integrated into the product surface, resulting in durable, high-quality aesthetics. Post-mold labeling, while easier to customize quickly, often faces limitations in adhesion, alignment, and wear resistance, which can compromise the overall visual appeal. The seamless integration in in-mold labeling reduces peeling and fading, making it ideal for applications requiring long-lasting branding and intricate designs.

Environmental Impact and Sustainability Considerations

In-mold labeling (IML) significantly reduces environmental impact by integrating labels during the molding process, minimizing waste and energy consumption compared to post-mold labeling (PML), which often involves additional adhesive use and separate application steps. Sustainable practices favor IML because it produces recyclable, contamination-free products that enhance circular economy efforts, whereas PML labels may complicate recycling due to mixed materials. Your choice between IML and PML directly influences your product's ecological footprint, with IML offering superior sustainability benefits by streamlining manufacturing and reducing landfill contributions.

Industry Applications and Use Cases

In-mold labeling (IML) offers superior durability and aesthetic appeal, making it ideal for food packaging, consumer goods, and automotive parts where high-quality, tamper-resistant labels are essential. Post-mold labeling is commonly used in applications requiring flexibility and lower upfront costs, such as promotional items, electronics, and short production runs with frequent label updates. Your choice depends on production volume, label longevity, and application requirements, with IML gaining preference in industries demanding robust, integrated labeling solutions.

Choosing the Right Labeling Method for Your Product

Choosing the right labeling method for your product depends on durability, cost, and appearance requirements. In-mold labeling integrates the label during the molding process, resulting in a seamless, highly durable finish ideal for long-lasting products. Post-mold labeling is more flexible and cost-effective for small batches or promotional items but may have less resistance to wear and chemicals.

In-mold Labeling vs Post-mold Labeling Infographic

libmatt.com

libmatt.com