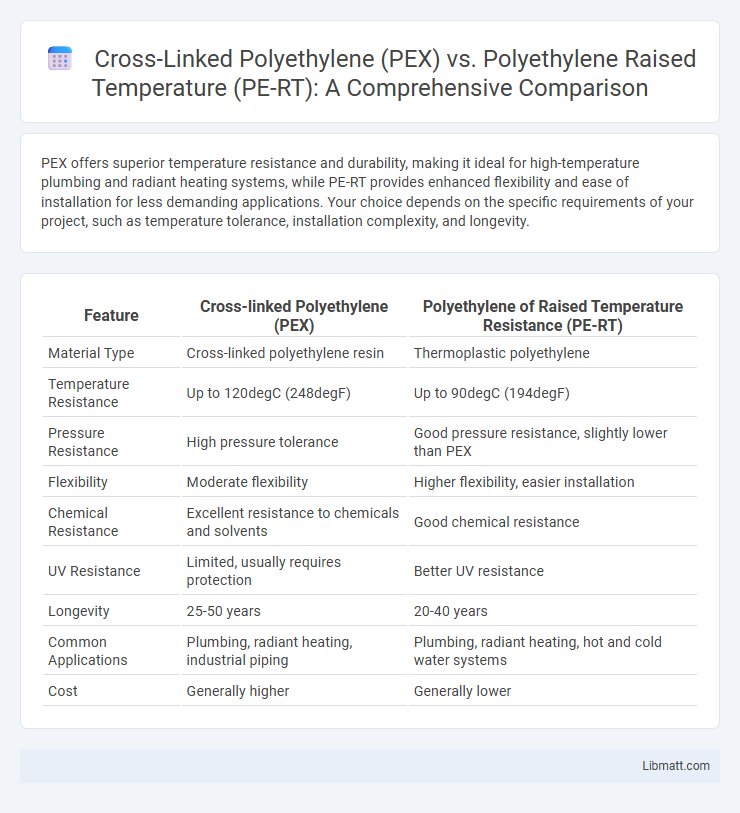

PEX offers superior temperature resistance and durability, making it ideal for high-temperature plumbing and radiant heating systems, while PE-RT provides enhanced flexibility and ease of installation for less demanding applications. Your choice depends on the specific requirements of your project, such as temperature tolerance, installation complexity, and longevity.

Table of Comparison

| Feature | Cross-linked Polyethylene (PEX) | Polyethylene of Raised Temperature Resistance (PE-RT) |

|---|---|---|

| Material Type | Cross-linked polyethylene resin | Thermoplastic polyethylene |

| Temperature Resistance | Up to 120degC (248degF) | Up to 90degC (194degF) |

| Pressure Resistance | High pressure tolerance | Good pressure resistance, slightly lower than PEX |

| Flexibility | Moderate flexibility | Higher flexibility, easier installation |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Good chemical resistance |

| UV Resistance | Limited, usually requires protection | Better UV resistance |

| Longevity | 25-50 years | 20-40 years |

| Common Applications | Plumbing, radiant heating, industrial piping | Plumbing, radiant heating, hot and cold water systems |

| Cost | Generally higher | Generally lower |

Introduction to PEX and PE-RT

Cross-linked Polyethylene (PEX) is a high-performance polymer known for its enhanced thermal stability and chemical resistance, achieved through a cross-linking process that improves its durability in plumbing and heating applications. Polyethylene of Raised Temperature resistance (PE-RT) is a flexible, non-cross-linked polyethylene designed for high-temperature environments, offering excellent resistance to hydrolysis and stress cracking. Both materials are widely used in hydronic heating and potable water systems, with PEX providing superior mechanical strength and PE-RT allowing easier processing and recyclability.

Chemical Structure Comparison

Cross-linked Polyethylene (PEX) features a three-dimensional network of covalently bonded polymer chains, enhancing thermal and chemical resistance by restricting molecular movement. PE-RT (Polyethylene of Raised Temperature resistance) maintains a linear polymer structure with added antioxidants for improved flexibility and temperature endurance, without cross-linking. This fundamental structural difference defines PEX's superior durability and higher pressure tolerance compared to the more flexible and impact-resistant PE-RT.

Manufacturing Processes

Cross-linked Polyethylene (PEX) is produced through chemical cross-linking methods such as peroxide, silane, or radiation processes that enhance its thermal and mechanical properties by creating a three-dimensional network of polymer chains. PE-RT (Polyethylene of Raised Temperature resistance) is manufactured using catalytic polymerization, resulting in a linear polymer with enhanced temperature resistance and flexibility without the need for cross-linking. The manufacturing process differences lead to PEX having superior resistance to high temperatures and pressure, while PE-RT offers easier recyclability and simpler processing due to its non-cross-linked structure.

Mechanical Properties

Cross-linked Polyethylene (PEX) exhibits superior mechanical properties such as enhanced tensile strength, improved impact resistance, and better long-term thermal stability compared to PE-RT. PE-RT offers excellent flexibility and resistance to cyclic pressures but typically has lower cross-link density, resulting in reduced mechanical robustness under high stress. Choosing PEX can ensure greater durability and performance for applications requiring high mechanical reliability in piping and insulation systems.

Flexibility and Installation

Cross-linked Polyethylene (PEX) offers superior flexibility compared to PE-RT, allowing it to bend easily around obstacles and reduce the need for fittings during installation. This flexibility simplifies your plumbing or heating setup by enabling quicker and more adaptable installation in tight spaces. PE-RT, while less flexible, provides a balance of rigidity and heat resistance, making it suitable for applications where shape retention is crucial.

Temperature and Pressure Resistance

Cross-linked Polyethylene (PEX) exhibits superior temperature resistance, maintaining structural integrity up to 200degF (93degC) under high pressure conditions, making it ideal for hot water plumbing and radiant heating systems. PE-RT (Polyethylene of Raised Temperature resistance) can withstand temperatures up to 180degF (82degC) but is generally rated for lower pressure applications compared to PEX. Both materials offer excellent flexibility and corrosion resistance, yet PEX provides enhanced durability under prolonged thermal stress and elevated pressure requirements.

Longevity and Durability

Cross-linked Polyethylene (PEX) exhibits superior longevity and durability due to its enhanced molecular structure, which provides excellent resistance to heat, chemical degradation, and mechanical stress, allowing it to maintain performance for over 50 years in plumbing and radiant heating applications. PE-RT (Polyethylene of Raised Temperature Resistance) offers good flexibility and thermal resistance but typically has a shorter lifespan, generally around 25 to 40 years, due to its lesser cross-linking and susceptibility to oxidative degradation. Both materials resist corrosion better than metal pipes, but PEX's cross-linked network ensures greater durability under high-temperature and high-pressure conditions.

Application Areas

Cross-linked Polyethylene (PEX) is widely used in plumbing, radiant heating, and cooling systems due to its excellent resistance to high temperatures and pressure. PE-RT is preferred for hot and cold water supply lines and underfloor heating because of its flexibility and ease of installation while maintaining durability under thermal stress. Your choice between PEX and PE-RT depends on specific application requirements like temperature tolerance and installation complexity.

Cost and Availability

Cross-linked Polyethylene (PEX) generally has a higher upfront cost compared to Polyethylene of Raised Temperature resistance (PE-RT) due to its complex manufacturing process, but both materials are widely available in plumbing and radiant heating markets. PE-RT offers competitive pricing and easier installation, making it a cost-effective option for residential applications. Availability for PEX spans multiple global suppliers with extensive distribution networks, while PE-RT is increasingly accessible, especially in regions focusing on sustainable and flexible piping solutions.

Environmental Impact and Sustainability

Cross-linked Polyethylene (PEX) demonstrates durability and chemical resistance but presents challenges in recycling due to its cross-linked molecular structure, resulting in limited end-of-life options and contributing to environmental waste. PE-RT (Polyethylene of Raised Temperature resistance) offers enhanced recyclability and lower environmental impact by enabling simpler mechanical recycling processes and reduced energy consumption during manufacturing. PE-RT's increased sustainability profile aligns with growing regulatory demands for environmentally friendly materials in plumbing and heating applications.

Cross-linked Polyethylene (PEX) vs PE-RT Infographic

libmatt.com

libmatt.com