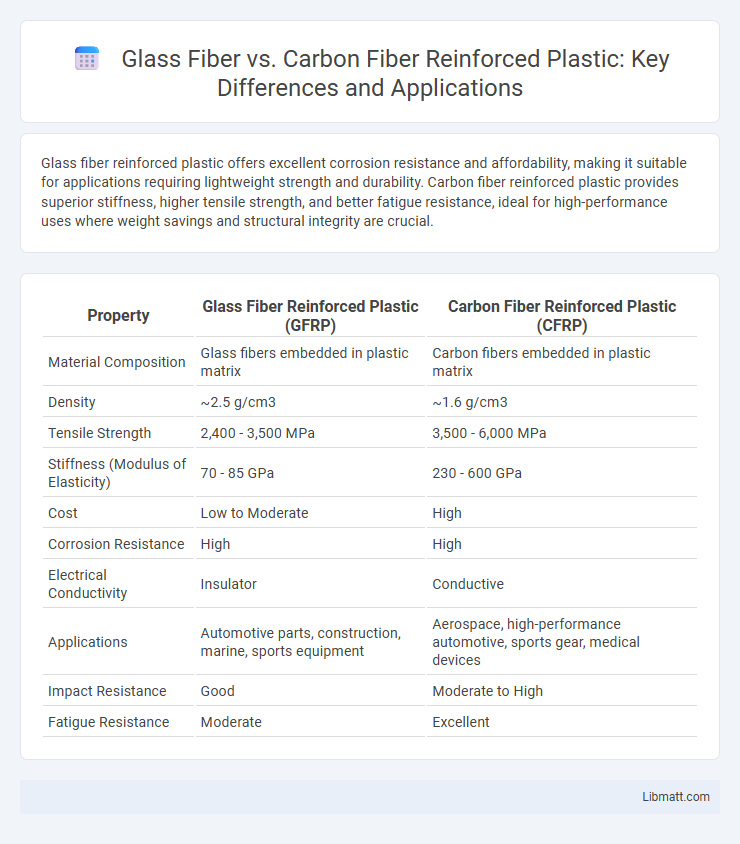

Glass fiber reinforced plastic offers excellent corrosion resistance and affordability, making it suitable for applications requiring lightweight strength and durability. Carbon fiber reinforced plastic provides superior stiffness, higher tensile strength, and better fatigue resistance, ideal for high-performance uses where weight savings and structural integrity are crucial.

Table of Comparison

| Property | Glass Fiber Reinforced Plastic (GFRP) | Carbon Fiber Reinforced Plastic (CFRP) |

|---|---|---|

| Material Composition | Glass fibers embedded in plastic matrix | Carbon fibers embedded in plastic matrix |

| Density | ~2.5 g/cm3 | ~1.6 g/cm3 |

| Tensile Strength | 2,400 - 3,500 MPa | 3,500 - 6,000 MPa |

| Stiffness (Modulus of Elasticity) | 70 - 85 GPa | 230 - 600 GPa |

| Cost | Low to Moderate | High |

| Corrosion Resistance | High | High |

| Electrical Conductivity | Insulator | Conductive |

| Applications | Automotive parts, construction, marine, sports equipment | Aerospace, high-performance automotive, sports gear, medical devices |

| Impact Resistance | Good | Moderate to High |

| Fatigue Resistance | Moderate | Excellent |

Introduction to Fiber Reinforced Plastics

Fiber Reinforced Plastics (FRPs) are composite materials made by embedding fibers such as glass or carbon within a plastic matrix, enhancing strength and durability. Glass fiber reinforced plastics (GFRP) offer excellent corrosion resistance and cost-effectiveness, while carbon fiber reinforced plastics (CFRP) deliver superior stiffness, strength-to-weight ratio, and fatigue resistance. Your choice between GFRP and CFRP depends on the specific performance requirements, budget, and application environment.

Composition and Manufacturing Processes

Glass fiber reinforced plastic (GFRP) consists of fine glass fibers embedded in a polymer matrix, commonly polyester or epoxy resin, produced through processes such as filament winding, hand lay-up, and pultrusion. Carbon fiber reinforced plastic (CFRP) features carbon fibers combined with epoxy resin or thermoplastic matrices, fabricated using advanced methods including autoclave curing, resin transfer molding (RTM), and prepreg lay-up. The choice of fibers and manufacturing techniques directly impacts the mechanical properties, weight, and cost-effectiveness of the final composite product.

Mechanical Properties Comparison

Glass fiber reinforced plastic offers high tensile strength and good impact resistance, making it suitable for applications requiring durability and flexibility. Carbon fiber reinforced plastic provides superior stiffness, higher tensile strength, and excellent fatigue resistance, ideal for aerospace and high-performance automotive components. When choosing between the two, your decision should consider the trade-offs in weight, cost, and specific mechanical demands of your project.

Weight and Density Differences

Glass fiber reinforced plastic (GFRP) typically has a density of around 2.5 g/cm3, which is higher than carbon fiber reinforced plastic (CFRP) with a density approximately 1.6 g/cm3, making CFRP significantly lighter for the same volume. The lower density of carbon fiber results in weight savings of up to 40% compared to glass fiber composites, crucial for aerospace and automotive industries aiming for fuel efficiency. Despite the weight advantage, the choice between GFRP and CFRP depends on cost considerations and specific mechanical requirements.

Cost Analysis: Glass Fiber vs. Carbon Fiber

Glass fiber reinforced plastic (GFRP) is significantly more cost-effective than carbon fiber reinforced plastic (CFRP), making it the preferred choice for applications with budget constraints. While CFRP offers superior strength-to-weight ratio and stiffness, its production costs are substantially higher due to expensive raw materials and complex manufacturing processes. You can optimize your project's budget by selecting glass fiber when cost efficiency outweighs the need for ultra-high performance.

Durability and Lifespan

Carbon fiber reinforced plastic offers superior durability and a longer lifespan compared to glass fiber reinforced plastic due to its higher tensile strength and resistance to fatigue. Glass fiber reinforced plastic provides good durability at a lower cost but may degrade faster under prolonged exposure to UV light and environmental stress. The superior chemical resistance and stiffness of carbon fiber composites contribute to their extended service life in demanding applications.

Typical Applications in Industry

Glass fiber reinforced plastic (GFRP) is widely used in automotive body panels, marine vessels, and construction due to its cost-effectiveness and excellent corrosion resistance. Carbon fiber reinforced plastic (CFRP) dominates aerospace, high-performance sports equipment, and luxury automotive components because of its superior strength-to-weight ratio and stiffness. Your choice depends on balancing budget constraints with performance requirements in industries like transportation, infrastructure, and sporting goods.

Environmental Considerations

Glass fiber reinforced plastic (GFRP) offers lower embodied energy and cost compared to carbon fiber reinforced plastic (CFRP), making it a more environmentally friendly choice for large-scale applications. CFRP provides superior strength-to-weight ratio and durability, reducing fuel consumption and emissions in transportation sectors, but its production involves higher energy use and challenges in recycling. Both materials face environmental concerns related to end-of-life disposal, with ongoing research focused on improving recyclability and adopting bio-based resins to minimize ecological impact.

Strengths and Limitations of Each Material

Glass fiber reinforced plastic offers excellent corrosion resistance, cost-effectiveness, and good tensile strength, making it ideal for marine and construction applications. Carbon fiber reinforced plastic provides superior strength-to-weight ratio, high stiffness, and fatigue resistance, suitable for aerospace and high-performance automotive uses. Limitations of glass fiber include lower strength and stiffness compared to carbon fiber, while carbon fiber's drawbacks are higher cost and susceptibility to impact damage.

Choosing the Right Material for Your Project

Glass fiber reinforced plastic offers excellent cost-efficiency and good impact resistance, making it ideal for projects requiring durability without breaking the budget. Carbon fiber reinforced plastic provides superior strength-to-weight ratio and stiffness, perfect for high-performance applications where weight savings and structural integrity are critical. Your choice depends on balancing budget constraints with performance needs, prioritizing glass fiber for affordability and carbon fiber for advanced strength.

Glass fiber vs carbon fiber reinforced plastic Infographic

libmatt.com

libmatt.com