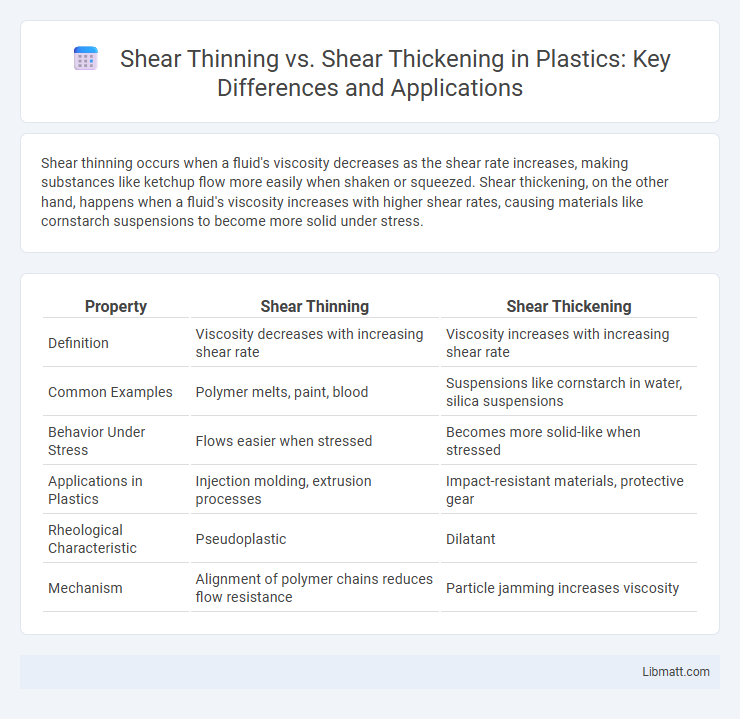

Shear thinning occurs when a fluid's viscosity decreases as the shear rate increases, making substances like ketchup flow more easily when shaken or squeezed. Shear thickening, on the other hand, happens when a fluid's viscosity increases with higher shear rates, causing materials like cornstarch suspensions to become more solid under stress.

Table of Comparison

| Property | Shear Thinning | Shear Thickening |

|---|---|---|

| Definition | Viscosity decreases with increasing shear rate | Viscosity increases with increasing shear rate |

| Common Examples | Polymer melts, paint, blood | Suspensions like cornstarch in water, silica suspensions |

| Behavior Under Stress | Flows easier when stressed | Becomes more solid-like when stressed |

| Applications in Plastics | Injection molding, extrusion processes | Impact-resistant materials, protective gear |

| Rheological Characteristic | Pseudoplastic | Dilatant |

| Mechanism | Alignment of polymer chains reduces flow resistance | Particle jamming increases viscosity |

Introduction to Shear Thinning and Shear Thickening

Shear thinning and shear thickening describe how certain fluids change viscosity under stress. Shear thinning fluids decrease in viscosity when subjected to increased shear rates, making them ideal for applications like paint and blood flow. Shear thickening fluids, such as cornstarch in water, increase in viscosity with stress, providing impact resistance in protective gear and industrial processes.

Defining Shear Thinning: Key Characteristics

Shear thinning describes a non-Newtonian fluid behavior where viscosity decreases with increasing shear rate, allowing easier flow under stress. Key characteristics include a reduction in resistance during processes like stirring or pumping, common in substances such as ketchup or blood. Understanding shear thinning helps you optimize applications involving fluid flow and processing efficiency.

Understanding Shear Thickening: Essential Features

Shear thickening is a non-Newtonian fluid behavior where viscosity increases with the applied shear rate, often observed in dense suspensions like cornstarch in water. Key features include reversible viscosity changes, the formation of particle clusters under stress, and potential jamming that leads to solid-like behavior. This phenomenon contrasts with shear thinning, where viscosity decreases as shear rate rises, highlighting the importance of particle interactions and suspension concentration in rheological responses.

The Science Behind Viscosity Changes

Shear thinning and shear thickening describe how a fluid's viscosity changes in response to applied stress or shear rate. Shear thinning occurs when viscosity decreases as shear rate increases, commonly found in non-Newtonian fluids like ketchup or blood due to the alignment of molecules reducing internal resistance. Shear thickening, observed in materials like cornstarch suspensions, happens when viscosity increases with shear rate as particle interactions create temporary structures that resist flow, impacting your handling of such fluids in industrial or everyday applications.

Common Examples of Shear Thinning Materials

Shear thinning materials, also known as pseudoplastic fluids, decrease in viscosity as the shear rate increases, exemplified by substances like ketchup, blood, and paint. These materials allow for easier flow under stress, making them ideal for applications in food processing, cosmetics, and biomedical fields. Understanding shear thinning behavior can improve your handling and formulation of products requiring consistent flow under varying forces.

Everyday Applications of Shear Thickening Fluids

Shear thickening fluids, which increase in viscosity under stress, are commonly used in everyday applications such as protective gear, including body armor and sports padding, where impact resistance is crucial. These fluids enable flexible materials to harden instantly upon impact, offering enhanced safety without sacrificing comfort or mobility. Your daily activities benefit from their ability to provide dynamic protection in items like helmets, gloves, and shock-absorbing footwear.

Molecular Mechanisms Driving Shear Behavior

Shear thinning occurs when polymer chains or particle suspensions align and disentangle under applied stress, reducing viscosity as internal resistance decreases. Conversely, shear thickening involves the formation of transient particle clusters or hydrocluster networks that increase resistance and viscosity under higher shear rates. Understanding these molecular mechanisms can help you tailor material properties for optimized performance in applications like coatings, food products, and biomedical fluids.

Industrial Implications: Choosing the Right Rheology

Shear thinning fluids, like paint and ketchup, decrease in viscosity under stress, making them ideal for applications requiring easy spreading or pumping. Shear thickening materials, such as cornstarch suspensions, increase viscosity when stressed, providing impact protection or stability in industrial processes. Understanding your product's shear behavior ensures optimal processing conditions and enhances performance in manufacturing, coating, and material handling operations.

Experimental Methods for Measuring Shear Responses

Rheometers and viscometers are primary experimental devices used to measure shear thinning and shear thickening behaviors in non-Newtonian fluids by applying controlled shear rates and recording viscosity changes. Techniques like steady shear tests and oscillatory shear measurements enable precise characterization of fluid response under varying shear stresses. Understanding these shear responses through your experimental setup ensures accurate analysis of material properties essential for applications in industries such as polymers, food processing, and pharmaceuticals.

Future Trends in Smart Fluids and Advanced Materials

Future trends in smart fluids emphasize the development of tunable shear-thinning materials that adapt viscosity under varying shear rates for applications in biomedical devices and soft robotics. Research on shear-thickening fluids is advancing toward impact-resistant protective gear and adaptive damping systems by exploiting reversible viscosity increases under stress. Integration of nanomaterials and stimuli-responsive polymers continues to enhance the performance and versatility of both shear-thinning and shear-thickening fluids in advanced materials science.

Shear thinning vs shear thickening Infographic

libmatt.com

libmatt.com