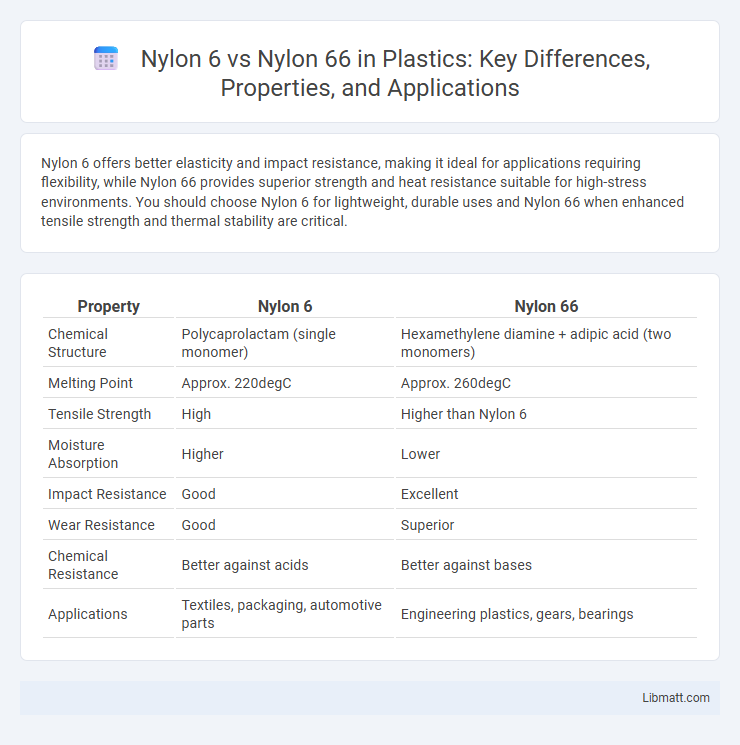

Nylon 6 offers better elasticity and impact resistance, making it ideal for applications requiring flexibility, while Nylon 66 provides superior strength and heat resistance suitable for high-stress environments. You should choose Nylon 6 for lightweight, durable uses and Nylon 66 when enhanced tensile strength and thermal stability are critical.

Table of Comparison

| Property | Nylon 6 | Nylon 66 |

|---|---|---|

| Chemical Structure | Polycaprolactam (single monomer) | Hexamethylene diamine + adipic acid (two monomers) |

| Melting Point | Approx. 220degC | Approx. 260degC |

| Tensile Strength | High | Higher than Nylon 6 |

| Moisture Absorption | Higher | Lower |

| Impact Resistance | Good | Excellent |

| Wear Resistance | Good | Superior |

| Chemical Resistance | Better against acids | Better against bases |

| Applications | Textiles, packaging, automotive parts | Engineering plastics, gears, bearings |

Introduction to Nylon 6 and Nylon 66

Nylon 6 and Nylon 66 are two widely used synthetic polymers with distinct molecular structures influencing their properties. Nylon 6 is made from caprolactam, offering excellent toughness and elasticity, while Nylon 66 is produced by polycondensation of hexamethylenediamine and adipic acid, providing superior thermal resistance and mechanical strength. Understanding these differences helps you select the appropriate nylon variant for applications demanding specific durability, temperature tolerance, and wear resistance.

Chemical Structure Comparison

Nylon 6 consists of a single type of monomer, caprolactam, which polymerizes to form a repeating unit with six carbon atoms, whereas Nylon 66 is produced from two monomers, hexamethylene diamine and adipic acid, each containing six carbon atoms. This structural difference influences the properties of each polymer, with Nylon 66 exhibiting higher melting points and superior abrasion resistance due to its more symmetrical molecular structure and increased hydrogen bonding. Understanding these chemical distinctions can help you select the appropriate nylon type based on performance requirements in applications like textiles, automotive parts, or industrial components.

Manufacturing Processes

Nylon 6 is produced through the ring-opening polymerization of caprolactam, a single monomer process that allows for straightforward and efficient manufacturing. Nylon 66 is synthesized by the polycondensation of hexamethylene diamine and adipic acid, requiring a two-step process that offers precise control over polymer structure. Understanding these differences in manufacturing processes helps optimize material selection for your specific application needs.

Mechanical Properties Overview

Nylon 6 offers excellent impact resistance and flexibility with tensile strength typically ranging from 70 to 80 MPa, while Nylon 66 exhibits higher heat resistance and superior mechanical strength, often reaching tensile strengths up to 90 MPa. Both materials provide good wear resistance, but Nylon 66 shows enhanced stiffness and dimensional stability under load, making it suitable for demanding applications. Your choice between Nylon 6 and Nylon 66 will depend on the balance you need between toughness, thermal resistance, and mechanical durability.

Thermal and Chemical Resistance

Nylon 6 offers good thermal resistance with a melting point around 220degC, while Nylon 66 withstands higher temperatures up to 260degC, making it more suitable for high-heat applications. Chemically, Nylon 66 exhibits superior resistance to oils, fuels, and solvents compared to Nylon 6, which can absorb more moisture and degrade faster in aggressive environments. Understanding these differences helps you select the right material for durability and performance under thermal and chemical stress.

Applications and Uses

Nylon 6, known for its excellent elasticity and abrasion resistance, is widely used in textiles, automotive parts, and packaging films, offering versatility for various industrial applications. Nylon 66 features higher melting points and superior mechanical strength, making it ideal for high-performance engineering components such as gears, bearings, and electrical insulation. Your choice between Nylon 6 and Nylon 66 depends on the specific durability and temperature resistance requirements of your project.

Environmental Impact and Sustainability

Nylon 6 and Nylon 66 differ significantly in environmental impact and sustainability; Nylon 6 is often favored due to its ability to be recycled more efficiently through chemical recycling back into caprolactam, reducing landfill waste and resource consumption. Nylon 66, produced from adipic acid and hexamethylene diamine, involves a more energy-intensive process with higher greenhouse gas emissions, notably from adipic acid production. You can make a more eco-conscious choice by selecting Nylon 6 for applications where recyclability and a smaller carbon footprint are priorities.

Cost Analysis: Nylon 6 vs Nylon 66

Nylon 6 generally offers a lower production cost compared to Nylon 66 due to its simpler polymerization process and availability of raw materials like caprolactam. Nylon 66 tends to be more expensive because it requires hexamethylene diamine and adipic acid, both of which involve more complex synthesis and higher material expenses. Cost differences influence applications, with Nylon 6 favored in cost-sensitive industries and Nylon 66 chosen for high-performance demands despite the premium price.

Performance in Industrial Settings

Nylon 6 offers superior flexibility and impact resistance, making it ideal for applications requiring high toughness and elongation. Nylon 66 excels in thermal stability and wear resistance, ensuring durability under high-temperature industrial conditions. Your choice between Nylon 6 and Nylon 66 should align with the specific demands of the operational environment for optimal performance.

Summary and Choosing the Right Nylon

Nylon 6 offers superior impact resistance and elasticity, making it ideal for applications requiring flexibility, while Nylon 66 exhibits higher heat resistance and tensile strength, suitable for demanding mechanical uses. Both materials feature excellent chemical resistance and abrasion durability, but Nylon 66's higher melting point supports high-temperature environments better. When choosing the right nylon for Your project, consider whether flexibility or thermal and mechanical performance is the priority to optimize material efficiency and longevity.

Nylon 6 vs Nylon 66 Infographic

libmatt.com

libmatt.com