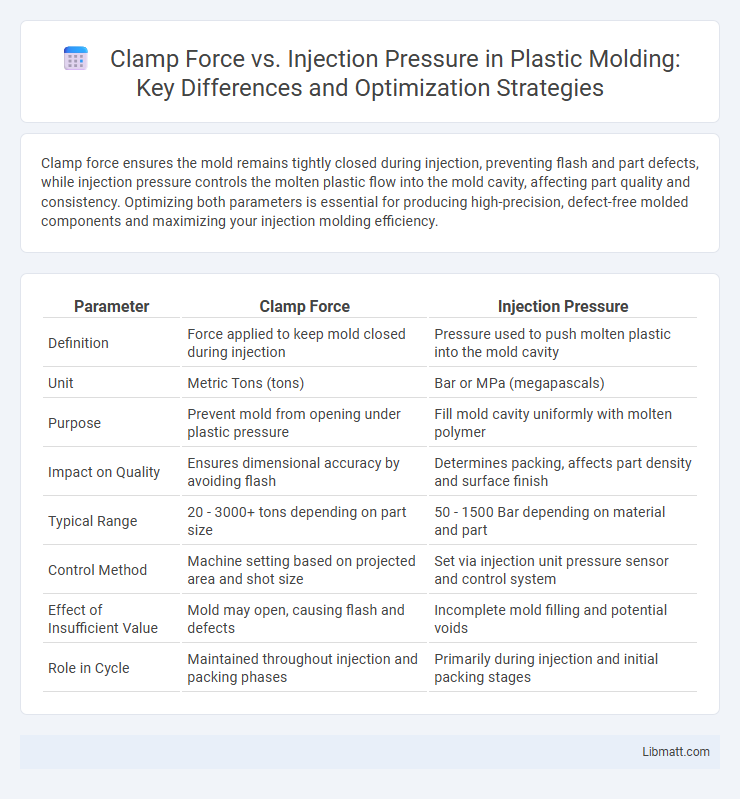

Clamp force ensures the mold remains tightly closed during injection, preventing flash and part defects, while injection pressure controls the molten plastic flow into the mold cavity, affecting part quality and consistency. Optimizing both parameters is essential for producing high-precision, defect-free molded components and maximizing your injection molding efficiency.

Table of Comparison

| Parameter | Clamp Force | Injection Pressure |

|---|---|---|

| Definition | Force applied to keep mold closed during injection | Pressure used to push molten plastic into the mold cavity |

| Unit | Metric Tons (tons) | Bar or MPa (megapascals) |

| Purpose | Prevent mold from opening under plastic pressure | Fill mold cavity uniformly with molten polymer |

| Impact on Quality | Ensures dimensional accuracy by avoiding flash | Determines packing, affects part density and surface finish |

| Typical Range | 20 - 3000+ tons depending on part size | 50 - 1500 Bar depending on material and part |

| Control Method | Machine setting based on projected area and shot size | Set via injection unit pressure sensor and control system |

| Effect of Insufficient Value | Mold may open, causing flash and defects | Incomplete mold filling and potential voids |

| Role in Cycle | Maintained throughout injection and packing phases | Primarily during injection and initial packing stages |

Understanding Clamp Force in Injection Molding

Clamp force in injection molding is the critical pressure applied by the machine's platens to keep the mold closed during material injection, preventing flash and ensuring cavity integrity. Injection pressure refers to the force required to inject molten plastic into the mold cavities, which must be balanced carefully with clamp force to avoid mold damage or part defects. Optimal clamp force ensures proper mold sealing, supporting efficient injection pressure application, and producing high-quality molded parts with minimal material waste.

Defining Injection Pressure: Key Concepts

Injection pressure refers to the force exerted by the injection molding machine to push molten plastic into the mold cavity, measured typically in megapascals (MPa). It directly influences the flow rate and filling time, affecting part quality and dimensional accuracy. Understanding injection pressure helps optimize Your process by ensuring proper mold filling while preventing defects like flash or short shots.

The Relationship Between Clamp Force and Injection Pressure

Clamp force and injection pressure directly influence the quality and accuracy of molded parts in injection molding processes. Higher injection pressure requires an increase in clamp force to prevent mold separation and maintain consistent cavity filling, ensuring dimensional stability and reducing defects. You should optimize clamp force relative to injection pressure to achieve efficient plastic flow and precise molding outcomes.

Factors Influencing Clamp Force Requirements

Clamp force requirements depend on part size, material type, and mold cavity surface area influencing the pressure needed to keep the mold closed during injection. Injection pressure varies with melt viscosity, injection speed, and temperature, affecting the necessary clamp force to prevent flash and ensure proper part formation. Optimizing these parameters minimizes cycle time and reduces wear on machinery while maintaining quality in molded parts.

Determining Optimal Injection Pressure Settings

Determining optimal injection pressure settings involves balancing clamp force to prevent mold separation while avoiding excessive pressure that may cause flash or part defects. High injection pressure requires sufficient clamp force to maintain mold integrity during the injection cycle, ensuring consistent part quality and dimensional accuracy. Your process efficiency improves by fine-tuning pressure parameters based on material flow characteristics and mold design to optimize cycle time and reduce scrap rates.

Effects of Insufficient Clamp Force

Insufficient clamp force during injection molding leads to mold separation, causing flash defects and dimensional inaccuracies in your parts. This condition increases the likelihood of material leakage and compromises the structural integrity of the final product. Maintaining optimal clamp force ensures proper cavity sealing, minimizing waste and enhancing product quality.

Risks of Excessive Injection Pressure

Excessive injection pressure can lead to flash formation, mold damage, and increased wear on the injection molding machine, resulting in higher maintenance costs and production downtime. High pressure may also cause part defects such as sink marks, warpage, or internal stresses that compromise product quality and durability. To protect your mold and ensure optimal part performance, carefully balance clamp force and injection pressure based on material characteristics and mold design.

Balancing Clamp Force and Injection Pressure for Quality Parts

Optimizing clamp force and injection pressure is essential for producing high-quality injection-molded parts. Insufficient clamp force can cause flash defects, while excessive force may damage the mold or increase wear, and improper injection pressure can lead to short shots or sink marks. Balancing these parameters ensures dimensional accuracy, consistent fill patterns, and structural integrity in the final product.

Common Problems and Solutions in Clamp Force vs Injection Pressure

Common problems in clamp force versus injection pressure include insufficient clamp force causing mold flash and excessive clamp force leading to mold damage or increased machine wear. Solutions involve accurately matching clamp force to injection pressure requirements by using real-time monitoring systems and adjusting settings based on part geometry and material properties. Employing feedback control mechanisms helps maintain optimal balance, ensuring product quality and prolonging equipment lifespan.

Best Practices for Managing Clamp Force and Injection Pressure

Optimal management of clamp force and injection pressure involves precisely balancing the two to avoid mold damage and ensure product quality. Best practices include regularly calibrating the clamp force to match the injection pressure, monitoring real-time sensor data to prevent over-packing or flash, and adjusting injection pressure profiles based on material viscosity and part geometry. Implementing closed-loop control systems enhances process stability by maintaining consistent cavity pressure and minimizing cycle time fluctuations.

Clamp Force vs Injection Pressure Infographic

libmatt.com

libmatt.com