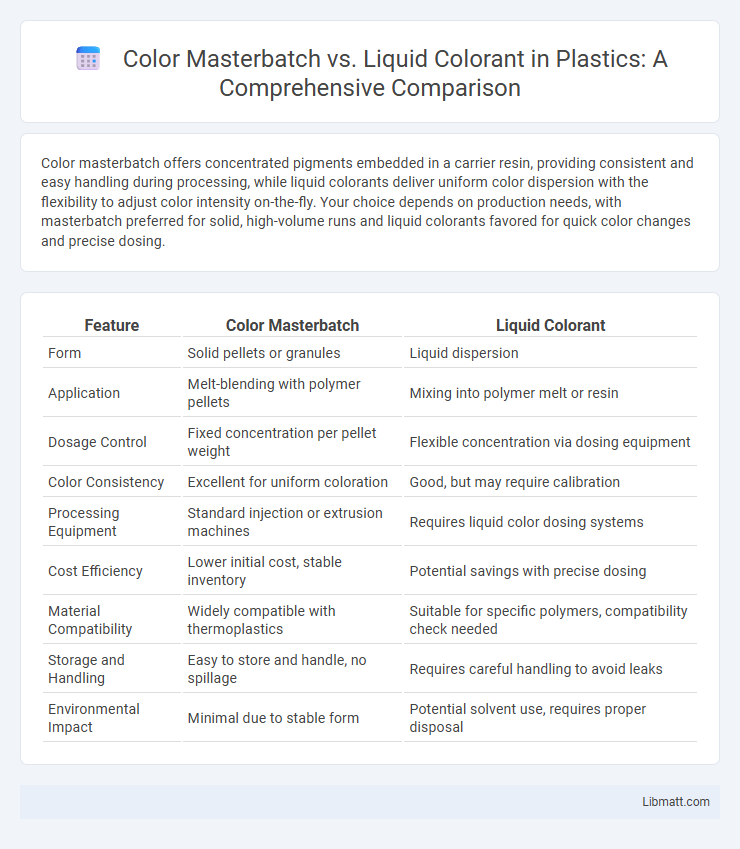

Color masterbatch offers concentrated pigments embedded in a carrier resin, providing consistent and easy handling during processing, while liquid colorants deliver uniform color dispersion with the flexibility to adjust color intensity on-the-fly. Your choice depends on production needs, with masterbatch preferred for solid, high-volume runs and liquid colorants favored for quick color changes and precise dosing.

Table of Comparison

| Feature | Color Masterbatch | Liquid Colorant |

|---|---|---|

| Form | Solid pellets or granules | Liquid dispersion |

| Application | Melt-blending with polymer pellets | Mixing into polymer melt or resin |

| Dosage Control | Fixed concentration per pellet weight | Flexible concentration via dosing equipment |

| Color Consistency | Excellent for uniform coloration | Good, but may require calibration |

| Processing Equipment | Standard injection or extrusion machines | Requires liquid color dosing systems |

| Cost Efficiency | Lower initial cost, stable inventory | Potential savings with precise dosing |

| Material Compatibility | Widely compatible with thermoplastics | Suitable for specific polymers, compatibility check needed |

| Storage and Handling | Easy to store and handle, no spillage | Requires careful handling to avoid leaks |

| Environmental Impact | Minimal due to stable form | Potential solvent use, requires proper disposal |

Introduction to Color Masterbatch and Liquid Colorant

Color masterbatch consists of concentrated pigments encapsulated within a carrier resin, providing consistent and uniform color when mixed with raw polymers during manufacturing. Liquid colorants are pigment dispersions suspended in a liquid base, allowing easier dosing and faster dispersion into polymer matrices for precise color control. Understanding these options helps optimize your production efficiency and product quality based on specific application requirements.

Composition and Manufacturing Process

Color masterbatch consists of a polymer carrier infused with high concentrations of pigment or additives, produced through a compounding process that extrudes and pelletizes the mixture for uniform distribution. Liquid colorants blend pigments or dyes in a solvent or resin carrier, manufactured by dispersing colorants into a liquid medium to ensure precise dosing and rapid mixing in production. The solid form of masterbatch favors long-term storage and easy handling, while liquid colorants offer flexibility in color intensity adjustment and are ideal for lower volume applications.

Application Methods in Plastics

Color masterbatch offers a convenient and consistent method for coloring plastics through dry blending or extrusion, ensuring uniform dispersion of pigments in solid resin pellets. Liquid colorants provide flexibility with precise dosing and rapid color changes, making them ideal for injection molding and blow molding applications where color accuracy and process efficiency are critical. Your choice depends on production volume, equipment compatibility, and the desired color intensity in the final plastic product.

Color Consistency and Quality

Color masterbatch ensures superior color consistency and quality due to its uniform dispersion of pigments within a polymer carrier, resulting in stable color output across various production runs. Liquid colorants offer good color vibrancy but may face challenges in achieving uniform dispersion, potentially leading to variability in color intensity and appearance. Manufacturers prioritize masterbatch for applications requiring precise color matching and long-term consistency in plastics and polymers.

Flexibility and Customization Options

Color masterbatch offers high flexibility in color intensity and pigment concentration, allowing precise customization for various polymer applications. Liquid colorants provide superior adaptability with easier mixing and uniform dispersion, ideal for small batch production and rapid color changes. Both options enable tailored color solutions, but liquid colorants excel in quick adjustments while masterbatches suit large-scale consistent coloring needs.

Cost Considerations and Efficiency

Color masterbatch offers lower upfront costs and easier handling, reducing waste and downtime in high-volume production, making it cost-efficient for large-scale manufacturing. Liquid colorants, while often more expensive initially, provide superior dispersion and color consistency, enhancing efficiency in processes requiring precise color control. Choosing between them depends on balancing budget constraints with desired production quality and operational efficiency.

Environmental Impact and Sustainability

Color masterbatch typically has a lower environmental footprint due to its concentrated form, reducing packaging waste and transportation energy compared to liquid colorants. Liquid colorants often require more complex handling and solvent use, potentially increasing emissions and disposal challenges. Choosing color masterbatch can enhance your sustainability efforts by minimizing resource consumption and supporting eco-friendlier manufacturing processes.

Storage, Handling, and Shelf Life

Color masterbatch offers easier storage and handling due to its solid pellet form, providing a longer shelf life typically exceeding 12 months under proper conditions. Liquid colorants require specialized storage tanks and temperature control to maintain consistency, with a shorter shelf life generally ranging from 6 to 12 months. Both require careful handling to avoid contamination, but masterbatch is less sensitive to environmental factors compared to liquid colorants.

Performance in Different Resin Systems

Color masterbatch offers improved dispersion and color stability across a wide range of resin systems such as polyethylene, polypropylene, and PVC, making it suitable for high-temperature processing and injection molding. Liquid colorants provide superior color uniformity and faster pigment dispersion, especially in extrusion and blow molding processes, but may have compatibility limitations with specific resins and require specialized dosing equipment. Selecting between color masterbatch and liquid colorant depends on resin type, processing conditions, and desired color consistency in applications like film, fibers, and rigid packaging.

Choosing the Right Color Solution for Your Needs

Color masterbatch offers a high concentration of pigments in a solid carrier, making it ideal for consistent, large-scale plastic coloring with excellent color stability and longer shelf life. Liquid colorants provide superior dispersion and flexibility, suitable for small batches, quick color changes, and intricate injection molding processes requiring precise color matching. Selecting between masterbatch and liquid colorants depends on production volume, color complexity, compatibility with the polymer, and processing equipment to optimize cost-efficiency and product quality.

Color masterbatch vs liquid colorant Infographic

libmatt.com

libmatt.com