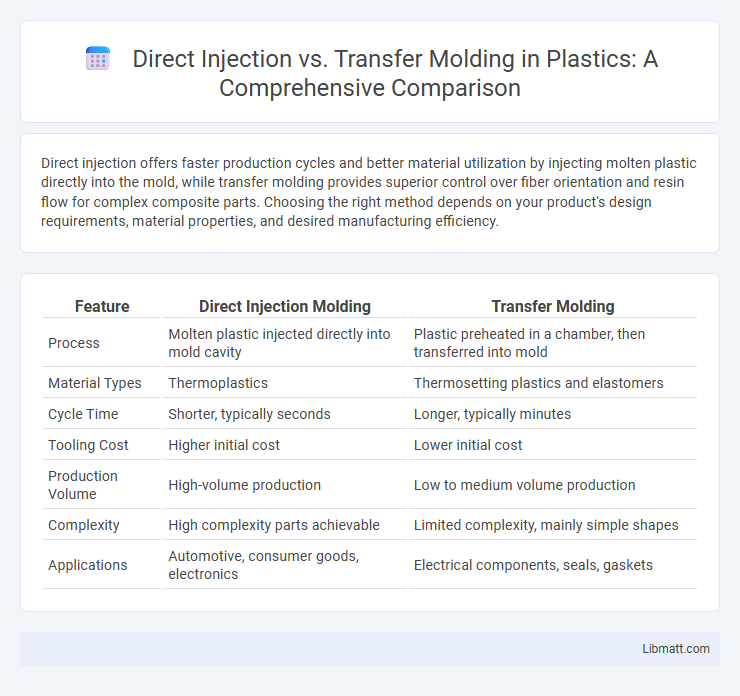

Direct injection offers faster production cycles and better material utilization by injecting molten plastic directly into the mold, while transfer molding provides superior control over fiber orientation and resin flow for complex composite parts. Choosing the right method depends on your product's design requirements, material properties, and desired manufacturing efficiency.

Table of Comparison

| Feature | Direct Injection Molding | Transfer Molding |

|---|---|---|

| Process | Molten plastic injected directly into mold cavity | Plastic preheated in a chamber, then transferred into mold |

| Material Types | Thermoplastics | Thermosetting plastics and elastomers |

| Cycle Time | Shorter, typically seconds | Longer, typically minutes |

| Tooling Cost | Higher initial cost | Lower initial cost |

| Production Volume | High-volume production | Low to medium volume production |

| Complexity | High complexity parts achievable | Limited complexity, mainly simple shapes |

| Applications | Automotive, consumer goods, electronics | Electrical components, seals, gaskets |

Introduction to Direct Injection and Transfer Molding

Direct injection molding involves injecting molten material directly into a mold cavity, offering precise control over part geometry and high production efficiency for complex components. Transfer molding uses a plunger to push preheated material from a pot into a closed mold, providing excellent replication of fine details and superior material flow for encapsulating inserts. Both methods are essential in manufacturing, with direct injection favored for thermoplastics and transfer molding commonly applied to thermosetting plastics and elastomers.

Defining Direct Injection Molding

Direct injection molding is a manufacturing process where molten material, typically plastic or rubber, is directly injected into a mold cavity to form a specific shape. This technique eliminates the need for pre-forming or transferring material, resulting in faster cycle times and higher precision. Direct injection molding is often favored for producing complex components with tight tolerances and improved surface finishes.

Understanding Transfer Molding Processes

Transfer molding is a manufacturing process where preheated material is forced from a chamber into a mold cavity through a runner system, offering precise control over component shape and dimensions. This method excels in producing complex parts with high strength and excellent surface finish, often used for encapsulating electronic components or creating intricate rubber parts. You benefit from reduced material waste and uniform part quality compared to direct injection molding, making transfer molding ideal for applications requiring detailed features and consistent material properties.

Key Differences Between Direct Injection and Transfer Molding

Direct injection involves injecting molten material directly into the mold cavity, offering precise control and minimal waste, while transfer molding transfers preheated material from a chamber into the mold, suitable for complex shapes with inserts. Direct injection typically allows faster cycle times and better surface finishes, whereas transfer molding provides superior filling of intricate mold details and improved material flow for thermosetting polymers. Material choice, production volume, and part complexity are critical factors influencing the selection between these molding techniques.

Material Compatibility and Selection

Direct injection molding accommodates a broad range of thermoplastics including polyethylene, polypropylene, and nylon, offering precise control over material flow and minimizing waste. Transfer molding primarily suits thermosetting plastics such as epoxy, phenolic, and silicone, providing enhanced thermal and chemical resistance but limited to less complex geometries. Material selection hinges on application requirements, with direct injection favored for high-production efficiency and transfer molding preferred for heat-resistant, durable components.

Production Efficiency and Cycle Time Comparison

Direct Injection offers superior production efficiency with shorter cycle times, typically ranging from 15 to 30 seconds per part, compared to Transfer Molding, which often requires 30 to 60 seconds or more. The reduced cycle time in Direct Injection results from precise material flow and automated processes, minimizing material waste and improving throughput. Your choice of Direct Injection can significantly enhance manufacturing speed and overall productivity in high-volume production environments.

Cost Analysis: Direct Injection vs Transfer Molding

Direct injection molding typically offers lower production costs per unit due to faster cycle times and reduced labor, making it ideal for high-volume manufacturing. Transfer molding involves higher initial tooling expenses and longer setup times but can be more cost-effective for complex parts requiring precise material flow and less waste. Your choice between the two methods should consider batch size, part complexity, and long-term cost efficiency to optimize overall production expenses.

Application Areas and Industry Use Cases

Direct injection molding is widely used in the automotive and consumer electronics industries for producing complex, high-precision components such as dashboard panels and smartphone casings. Transfer molding is preferred in the electrical and aerospace sectors due to its capability to encapsulate delicate parts like semiconductor devices and sensor housings with high thermal stability. Both methods serve medical device manufacturing, with direct injection enabling rapid prototyping and transfer molding ensuring robust insulation for implantable components.

Quality, Precision, and Defect Rate Considerations

Direct injection molding offers superior precision and higher-quality finishes due to its ability to inject material directly into the mold, minimizing material waste and reducing the risk of contamination. Transfer molding, while effective for intricate parts, often results in a higher defect rate because of increased material handling and potential flash formation. Choosing the right method impacts your production efficiency and product consistency, with direct injection generally delivering better quality control.

Choosing the Right Molding Technique for Your Project

Selecting the right molding technique depends on factors such as production volume, complexity, and material type. Direct injection offers precise control for high-volume projects with intricate designs, while transfer molding excels in creating robust parts with less material waste for medium to low volumes. Understanding your project's specific requirements ensures the optimal balance between cost-efficiency and product quality.

Direct Injection vs Transfer Molding Infographic

libmatt.com

libmatt.com