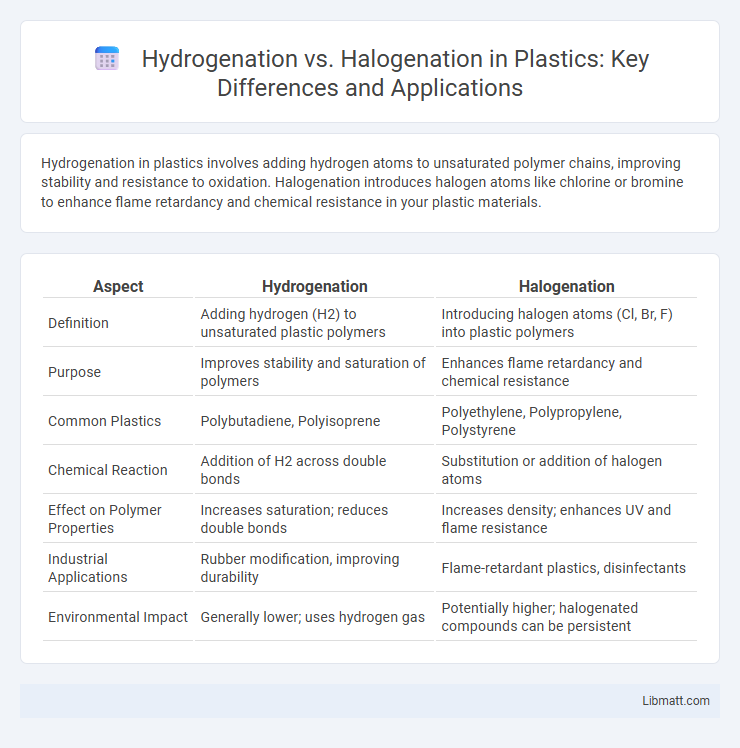

Hydrogenation in plastics involves adding hydrogen atoms to unsaturated polymer chains, improving stability and resistance to oxidation. Halogenation introduces halogen atoms like chlorine or bromine to enhance flame retardancy and chemical resistance in your plastic materials.

Table of Comparison

| Aspect | Hydrogenation | Halogenation |

|---|---|---|

| Definition | Adding hydrogen (H2) to unsaturated plastic polymers | Introducing halogen atoms (Cl, Br, F) into plastic polymers |

| Purpose | Improves stability and saturation of polymers | Enhances flame retardancy and chemical resistance |

| Common Plastics | Polybutadiene, Polyisoprene | Polyethylene, Polypropylene, Polystyrene |

| Chemical Reaction | Addition of H2 across double bonds | Substitution or addition of halogen atoms |

| Effect on Polymer Properties | Increases saturation; reduces double bonds | Increases density; enhances UV and flame resistance |

| Industrial Applications | Rubber modification, improving durability | Flame-retardant plastics, disinfectants |

| Environmental Impact | Generally lower; uses hydrogen gas | Potentially higher; halogenated compounds can be persistent |

Introduction to Hydrogenation and Halogenation in Plastics

Hydrogenation in plastics refers to the chemical process where hydrogen atoms are added to polymer chains, increasing saturation and enhancing material stability, flexibility, and resistance to oxidation. Halogenation involves incorporating halogen atoms such as chlorine or bromine into plastics, significantly improving flame retardancy, chemical resistance, and altering electrical properties. Both hydrogenation and halogenation are crucial in modifying polymer characteristics to meet specific application requirements in the plastics industry.

Chemical Definitions and Mechanisms

Hydrogenation in plastics involves the addition of hydrogen atoms to unsaturated carbon bonds, typically using catalysts like nickel or palladium, converting double bonds into single bonds and enhancing polymer stability and flexibility. Halogenation refers to the substitution or addition of halogen atoms (such as chlorine or bromine) into the polymer chain, which modifies properties like flame retardancy and chemical resistance by altering the polymer's molecular structure. Understanding these chemical mechanisms helps you tailor plastic materials for specific applications by controlling reactivity and durability through selective bond modification.

Key Differences Between Hydrogenation and Halogenation

Hydrogenation in plastics involves the addition of hydrogen atoms to unsaturated polymer chains, resulting in increased saturation, improved stability, and enhanced resistance to chemical degradation. Halogenation introduces halogen atoms such as chlorine or bromine into the polymer structure, which imparts flame retardant properties and alters chemical resistance. Key differences include the type of atoms added--hydrogen versus halogens--and the resulting changes in polymer characteristics, with hydrogenation primarily enhancing durability and halogenation primarily improving fire resistance.

Impact on Polymer Structure and Properties

Hydrogenation in plastics involves the addition of hydrogen to unsaturated polymer chains, increasing saturation and enhancing thermal stability, chemical resistance, and flexibility. Halogenation introduces halogen atoms, such as chlorine or bromine, into the polymer backbone, significantly improving flame retardancy and chemical resistance but potentially reducing flexibility and processability. The specific impact on polymer crystallinity, glass transition temperature, and mechanical strength varies depending on the degree and type of chemical modification, influencing final material performance in applications.

Industrial Applications in the Plastics Industry

Hydrogenation in plastics primarily enhances polymer stability and flexibility by saturating double bonds, widely used in producing hydrogenated nitrile rubber (HNBR) for automotive and industrial seals. Halogenation introduces halogen atoms like chlorine or bromine into polymers, improving flame retardancy and chemical resistance, critical for manufacturing fire-resistant cables and electronic housings. Both processes are essential in tailoring polymer properties to meet specific industrial standards in packaging, construction, and electronics.

Advantages of Hydrogenation in Polymer Processing

Hydrogenation in polymer processing enhances thermal stability and resistance to oxidation, resulting in longer-lasting plastics compared to those produced by halogenation. This process reduces unsaturation in polymer chains, improving color stability and mechanical properties without introducing toxic halogen residues. The absence of corrosive byproducts and improved environmental safety make hydrogenation a preferred method in creating durable and sustainable plastic materials.

Benefits and Risks of Halogenation in Plastics

Halogenation in plastics enhances flame retardancy, chemical resistance, and thermal stability, making materials safer and more durable in high-performance applications. However, halogenated plastics can release toxic gases like dioxins and furans during combustion, raising environmental and health concerns. Balancing these benefits and risks requires careful selection and disposal practices to mitigate long-term ecological impact.

Environmental Considerations and Safety

Hydrogenation in plastics reduces unsaturation by adding hydrogen, enhancing polymer stability and decreasing the risk of harmful byproducts, making it environmentally safer compared to halogenation. Halogenation introduces halogen atoms, which can lead to toxic and persistent environmental pollutants such as dioxins, posing significant safety concerns during manufacturing and disposal. When selecting processes, Your focus on minimizing ecological impact and ensuring workplace safety favors hydrogenation for a greener and less hazardous plastic production.

Recent Innovations in Polymer Modification

Recent innovations in polymer modification have enhanced the efficiency and selectivity of hydrogenation and halogenation processes in plastics. Advanced catalytic systems enable precise control over hydrogenation, improving polymer stability and mechanical properties without compromising flexibility. Halogenation techniques have evolved to incorporate environmentally friendly reagents, allowing for tailored surface properties and enhanced flame retardancy in your plastic materials.

Future Trends in Plastic Production Technologies

Future trends in plastic production technologies emphasize enhanced hydrogenation processes to improve polymer stability and reduce environmental impact by enabling more efficient saturation of carbon chains. Advances in halogenation focus on precise control of halogen incorporation to tailor polymer flame retardancy and chemical resistance without generating harmful byproducts. Integration of catalytic systems and green chemistry approaches in both hydrogenation and halogenation aims to optimize energy efficiency and sustainability in large-scale plastic manufacturing.

Hydrogenation vs halogenation (in plastics) Infographic

libmatt.com

libmatt.com