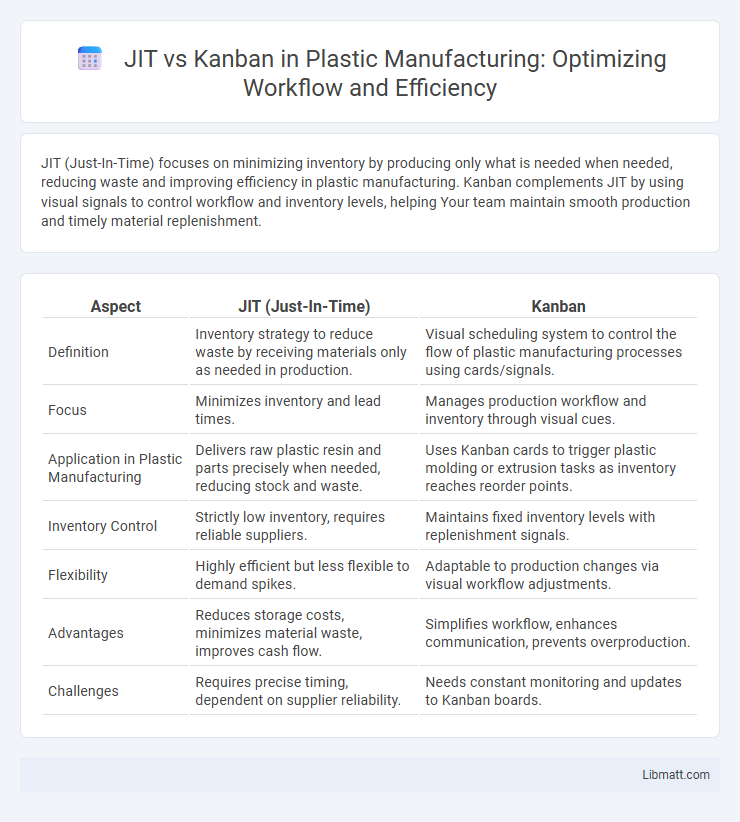

JIT (Just-In-Time) focuses on minimizing inventory by producing only what is needed when needed, reducing waste and improving efficiency in plastic manufacturing. Kanban complements JIT by using visual signals to control workflow and inventory levels, helping Your team maintain smooth production and timely material replenishment.

Table of Comparison

| Aspect | JIT (Just-In-Time) | Kanban |

|---|---|---|

| Definition | Inventory strategy to reduce waste by receiving materials only as needed in production. | Visual scheduling system to control the flow of plastic manufacturing processes using cards/signals. |

| Focus | Minimizes inventory and lead times. | Manages production workflow and inventory through visual cues. |

| Application in Plastic Manufacturing | Delivers raw plastic resin and parts precisely when needed, reducing stock and waste. | Uses Kanban cards to trigger plastic molding or extrusion tasks as inventory reaches reorder points. |

| Inventory Control | Strictly low inventory, requires reliable suppliers. | Maintains fixed inventory levels with replenishment signals. |

| Flexibility | Highly efficient but less flexible to demand spikes. | Adaptable to production changes via visual workflow adjustments. |

| Advantages | Reduces storage costs, minimizes material waste, improves cash flow. | Simplifies workflow, enhances communication, prevents overproduction. |

| Challenges | Requires precise timing, dependent on supplier reliability. | Needs constant monitoring and updates to Kanban boards. |

Introduction to JIT and Kanban in Plastic Manufacturing

Just-In-Time (JIT) and Kanban are essential methodologies in plastic manufacturing aimed at optimizing production efficiency and inventory management. JIT minimizes waste by producing plastic components only as needed, reducing overproduction and storage costs, while Kanban uses visual signals to control workflow and inventory replenishment, ensuring smooth and timely material supply. Implementing JIT and Kanban together enhances responsiveness to demand fluctuations, improves lead times, and supports lean manufacturing principles within plastic production facilities.

Core Principles of JIT in Plastic Production

Just-In-Time (JIT) in plastic manufacturing emphasizes minimizing inventory by producing only what is needed, when it is needed, to reduce waste and improve efficiency. Core principles include continuous flow, pull production triggered by downstream demand, and strict quality control to prevent defects and rework. JIT demands strong supplier relationships and synchronized processes to ensure timely delivery of raw plastic materials, maintaining lean operations throughout production cycles.

Fundamentals of Kanban Systems for Plastics Industry

Kanban systems in plastic manufacturing rely on visual signals, such as cards or bins, to control inventory levels and workflow, ensuring materials are replenished only when needed. This pull-based approach minimizes waste and reduces excess inventory, enhancing production efficiency and responsiveness to demand fluctuations. Your plastic production line benefits from improved lead times and streamlined processes by implementing these fundamental Kanban principles.

Comparing Process Flow: JIT vs Kanban

JIT in plastic manufacturing streamlines production by producing items exactly when needed, minimizing inventory and reducing waste through a pull-based system that responds to actual demand. Kanban enhances this by visually signaling production stages and inventory levels using cards or electronic boards, enabling real-time adjustments and smoother workflow within JIT frameworks. Together, JIT and Kanban optimize process flow by synchronizing material supply, improving production efficiency, and reducing lead times in plastic manufacturing operations.

Inventory Management: JIT versus Kanban Practices

In plastic manufacturing, Just-In-Time (JIT) inventory management minimizes stock by synchronizing production schedules with demand, reducing waste and storage costs. Kanban uses visual signals, such as cards or bins, to trigger replenishment only when inventory reaches a set threshold, ensuring continuous workflow without overproduction. Both systems enhance efficiency but Kanban offers more flexibility in managing variability, while JIT emphasizes exact timing and lean inventory levels.

Impact on Lead Times and Production Efficiency

JIT (Just-In-Time) in plastic manufacturing minimizes lead times by synchronizing material delivery precisely with production schedules, reducing inventory storage and accelerating workflow. Kanban enhances production efficiency through visual signaling systems that optimize task prioritization and inventory replenishment, preventing overproduction and bottlenecks. Both methodologies streamline operations, but JIT emphasizes timing accuracy while Kanban focuses on continuous flow and inventory control.

Quality Control: JIT vs Kanban Approaches

JIT in plastic manufacturing emphasizes continuous quality control by synchronizing production with demand, minimizing defects through real-time inspections and immediate corrective actions. Kanban relies on visual signals and inventory limits to regulate workflow, enhancing quality by preventing overproduction and enabling quick identification of quality issues within set batch sizes. Both systems integrate quality checkpoints but differ as JIT focuses on pull-based defect reduction, while Kanban prioritizes flow control and visual management to maintain product consistency.

Cost Implications in Plastic Manufacturing

Implementing JIT (Just-In-Time) in plastic manufacturing reduces inventory holding costs by minimizing raw material storage and work-in-progress stock, leading to lower capital tied up in excess inventory. Kanban systems optimize production flow through visual signaling, which decreases overproduction and waste, thereby lowering operational costs associated with material scrap and rework. Both strategies improve cash flow but JIT requires precise supplier reliability, while Kanban enhances cost efficiency through continuous, incremental inventory replenishment aligned with actual demand.

Implementation Challenges and Solutions

Implementation challenges of JIT in plastic manufacturing include high dependency on supplier reliability and risks of production delays due to minimal inventory buffers. Kanban systems face difficulties in visual management accuracy and synchronization across multiple production stages, often requiring continuous communication and training. Solutions involve establishing strong supplier relationships with real-time data exchange for JIT and utilizing digital Kanban boards coupled with employee engagement programs to enhance process transparency and responsiveness.

Choosing the Right System: Key Factors for Plastics Manufacturers

Plastics manufacturers must evaluate production volume, demand variability, and inventory costs when choosing between JIT and Kanban systems. JIT offers lean inventory and reduces waste, ideal for stable demand and efficient supplier relationships, while Kanban provides visual workflow control and adaptability for fluctuating production needs. The decision hinges on balancing operational flexibility with cost efficiency to optimize manufacturing performance.

JIT vs Kanban (plastic manufacturing) Infographic

libmatt.com

libmatt.com