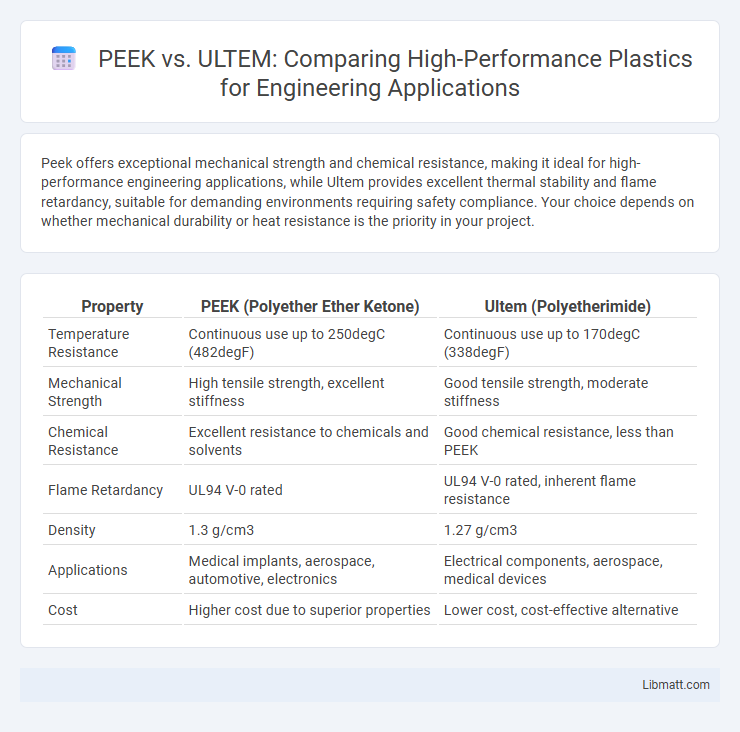

Peek offers exceptional mechanical strength and chemical resistance, making it ideal for high-performance engineering applications, while Ultem provides excellent thermal stability and flame retardancy, suitable for demanding environments requiring safety compliance. Your choice depends on whether mechanical durability or heat resistance is the priority in your project.

Table of Comparison

| Property | PEEK (Polyether Ether Ketone) | Ultem (Polyetherimide) |

|---|---|---|

| Temperature Resistance | Continuous use up to 250degC (482degF) | Continuous use up to 170degC (338degF) |

| Mechanical Strength | High tensile strength, excellent stiffness | Good tensile strength, moderate stiffness |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Good chemical resistance, less than PEEK |

| Flame Retardancy | UL94 V-0 rated | UL94 V-0 rated, inherent flame resistance |

| Density | 1.3 g/cm3 | 1.27 g/cm3 |

| Applications | Medical implants, aerospace, automotive, electronics | Electrical components, aerospace, medical devices |

| Cost | Higher cost due to superior properties | Lower cost, cost-effective alternative |

Introduction to PEEK and Ultem

PEEK (Polyether Ether Ketone) and Ultem (Polyetherimide) are high-performance thermoplastic polymers valued for their excellent mechanical strength and thermal stability. PEEK offers superior chemical resistance and can withstand continuous use temperatures up to 250degC, making it ideal for aerospace and medical applications. Ultem provides outstanding flame retardancy and dimensional stability at temperatures up to 217degC, commonly utilized in electrical and automotive industries.

Chemical Composition and Structure

PEEK (Polyether Ether Ketone) features a semi-crystalline structure composed of aromatic rings linked by ketone and ether groups, offering exceptional chemical resistance and thermal stability. Ultem (Polyetherimide) is an amorphous polymer consisting of aromatic rings connected by imide and ether linkages, providing high strength and thermal resistance but with different chemical stability compared to PEEK. Your choice between PEEK and Ultem depends on the desired balance between chemical resistance, molecular structure, and application-specific performance requirements.

Mechanical Strength Comparison

PEEK exhibits superior mechanical strength with tensile strength typically around 90-100 MPa, outperforming Ultem, which has a tensile strength closer to 80-90 MPa. The higher modulus of elasticity in PEEK, approximately 3.6-4.1 GPa, contributes to its enhanced stiffness and resistance to deformation under stress compared to Ultem's modulus of about 3.0-3.2 GPa. PEEK's durability under cyclic loading and higher impact resistance make it a preferred material in demanding mechanical applications over Ultem.

Thermal Resistance and Stability

PEEK offers superior thermal resistance with a melting point around 343degC and maintains mechanical stability in continuous use up to 250degC. Ultem, a polyetherimide, provides excellent thermal stability with a glass transition temperature around 217degC but cannot withstand melting like PEEK. Your choice depends on operating temperature demands, with PEEK favored for higher thermal resistance and Ultem suited for applications below 217degC requiring stable thermal performance.

Electrical Properties and Insulation

PEEK exhibits excellent electrical insulation properties with a dielectric strength of about 18-21 kV/mm and a low dielectric constant around 3.2, making it highly effective for high-frequency electrical applications. Ultem (PEI) possesses a dielectric strength of approximately 16-20 kV/mm and a dielectric constant near 3.5, providing reliable insulation performance in moderate electrical environments. Both materials offer superior thermal stability and flame resistance, but PEEK generally outperforms Ultem in terms of electrical resistivity and long-term dielectric durability under harsh conditions.

Chemical Resistance and Durability

PEEK exhibits superior chemical resistance against a broad spectrum of solvents, acids, and bases, making it ideal for harsh environments, while Ultem offers good chemical resistance but tends to degrade faster with prolonged exposure to strong acids and alkalis. In terms of durability, PEEK provides exceptional mechanical strength and high thermal stability up to 260degC, ensuring long-lasting performance in demanding applications; Ultem, though durable, withstands slightly lower temperatures around 217degC and may exhibit reduced toughness under extreme conditions. Your choice between PEEK and Ultem depends on the specific chemical exposure and temperature requirements of your application.

Processing and Machinability

PEEK offers superior dimensional stability and can be machined with greater precision due to its higher melting point of around 343degC, making it ideal for high-performance applications requiring tight tolerances. Ultem, with a lower melting point near 217degC, processes more easily through injection molding but can be more challenging to machine cleanly because of its toughness and tendency to soften under heat. Both materials benefit from optimized cutting speeds and coolant use during machining to maintain surface quality and prevent thermal degradation.

Applications in Various Industries

PEEK and Ultem are high-performance polymers widely used in aerospace, automotive, and medical industries due to their exceptional thermal stability and chemical resistance. PEEK's superior mechanical strength and wear resistance make it ideal for demanding engineering applications such as aircraft structural components and surgical implants. Ultem is preferred for electrical and electronic industries, offering excellent flame retardancy and electrical insulation in connectors, circuit boards, and semiconductor equipment.

Cost and Availability Analysis

PEEK (Polyether Ether Ketone) tends to have a higher price point compared to Ultem (Polyetherimide) due to its superior mechanical properties and chemical resistance, making it more suitable for high-performance applications. Ultem is generally more cost-effective and widely available, with extensive manufacturing infrastructure supporting quicker lead times and easier procurement. The choice between PEEK and Ultem often depends on budget constraints and the specific application requirements concerning thermal and chemical stability.

Choosing Between PEEK and Ultem

Choosing between PEEK and Ultem depends on specific application requirements such as temperature resistance, chemical stability, and mechanical strength. PEEK offers superior chemical resistance and can withstand continuous use temperatures up to 250degC, making it ideal for high-performance engineering applications. Ultem provides excellent flame retardancy and transparency with thermal stability up to 217degC, making it suitable for aerospace and electronic components where weight and safety regulations are critical.

PEEK vs Ultem Infographic

libmatt.com

libmatt.com