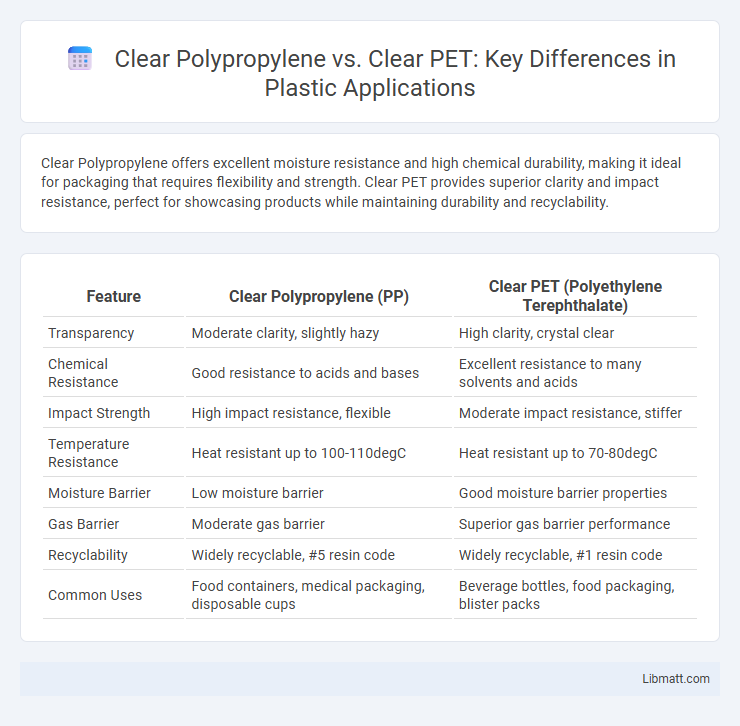

Clear Polypropylene offers excellent moisture resistance and high chemical durability, making it ideal for packaging that requires flexibility and strength. Clear PET provides superior clarity and impact resistance, perfect for showcasing products while maintaining durability and recyclability.

Table of Comparison

| Feature | Clear Polypropylene (PP) | Clear PET (Polyethylene Terephthalate) |

|---|---|---|

| Transparency | Moderate clarity, slightly hazy | High clarity, crystal clear |

| Chemical Resistance | Good resistance to acids and bases | Excellent resistance to many solvents and acids |

| Impact Strength | High impact resistance, flexible | Moderate impact resistance, stiffer |

| Temperature Resistance | Heat resistant up to 100-110degC | Heat resistant up to 70-80degC |

| Moisture Barrier | Low moisture barrier | Good moisture barrier properties |

| Gas Barrier | Moderate gas barrier | Superior gas barrier performance |

| Recyclability | Widely recyclable, #5 resin code | Widely recyclable, #1 resin code |

| Common Uses | Food containers, medical packaging, disposable cups | Beverage bottles, food packaging, blister packs |

Introduction to Clear Polypropylene and Clear PET

Clear Polypropylene (PP) and Clear Polyethylene Terephthalate (PET) are widely used transparent plastics in packaging and manufacturing. Clear PP offers excellent clarity, chemical resistance, and flexibility, making it ideal for food containers and consumer goods, while Clear PET is known for superior strength, durability, and recyclability, commonly used in beverage bottles and rigid packaging. Understanding the specific properties of these materials helps you choose the best option for your product's requirements.

Material Composition and Properties

Clear Polypropylene (PP) is a thermoplastic polymer made from propylene monomers, known for its high clarity, chemical resistance, and flexibility, making it ideal for packaging and labeling applications. Clear PET (Polyethylene Terephthalate) is a polyester polymer derived from ethylene glycol and terephthalic acid, offering superior rigidity, excellent gas barrier properties, and high impact resistance, commonly used in beverage bottles and food containers. While PP provides better heat resistance and flexibility, PET excels in strength and transparency, making material selection dependent on specific product requirements regarding durability and visual appeal.

Visual Clarity and Appearance

Clear Polypropylene (PP) offers excellent visual clarity with a high gloss finish and superior transparency, making it ideal for packaging that requires a bright and vibrant appearance. Clear PET (Polyethylene Terephthalate) provides slightly higher clarity and better resistance to yellowing over time, maintaining its bright and crisp look longer under exposure to light. Your choice between these materials should weigh PET's long-lasting brilliance against PP's crisp gloss for optimal product presentation.

Strength and Durability Comparison

Clear Polypropylene (CPP) offers high tensile strength and excellent flexibility, making it resistant to cracking under stress, while Clear PET (Polyethylene Terephthalate) excels in rigidity and impact resistance with superior durability in harsh environments. PET provides greater resistance to chemical degradation and UV exposure, enhancing its lifespan compared to CPP in outdoor applications. Both materials demonstrate strong moisture barriers, but PET's structural integrity under high temperatures surpasses that of CPP, making it favorable for long-term use requiring durability.

Barrier Properties: Moisture, Gas, and Chemical Resistance

Clear Polypropylene offers moderate moisture barrier properties but lower gas resistance compared to Clear PET, making it less effective in preserving oxygen-sensitive products. Clear PET provides superior barrier performance against gases, moisture, and chemicals, ensuring extended shelf life and protection for a wide range of applications. Choosing Clear PET for your packaging needs enhances durability and maintains product integrity in challenging environments.

Sustainability and Environmental Impact

Clear polypropylene (PP) and clear polyethylene terephthalate (PET) differ significantly in sustainability and environmental impact. Clear PET is widely recycled with established infrastructure, boasting a recycling rate of around 30%, while clear PP recycling remains limited but is improving due to new initiatives and better sorting technologies. PET production generally consumes more energy and emits higher CO2 levels compared to PP, but PP's lower density results in less material use per product, enhancing its environmental profile in lightweight applications.

Recyclability and Eco-Friendly Potential

Clear polypropylene (PP) offers excellent recyclability due to its high melting point and widespread acceptance in recycling programs, making it a preferred choice for sustainable packaging. Clear PET (polyethylene terephthalate) features superior clarity and is highly recyclable, with well-established recycling streams contributing to its eco-friendly profile. Both materials support circular economy efforts, but PET's stronger market demand and infrastructure often enhance its overall environmental benefits.

Cost Considerations and Market Availability

Clear polypropylene (PP) offers a lower production cost compared to clear polyethylene terephthalate (PET), making it a budget-friendly choice for packaging and manufacturing applications. PET demonstrates higher market availability due to its widespread use in beverage bottles and food containers, supported by robust recycling infrastructure and consumer demand. Cost efficiency of PP is balanced by PET's superior clarity and strength, influencing purchasing decisions based on project requirements and supply chain factors.

Typical Applications and Industry Uses

Clear Polypropylene is commonly used in food packaging, medical containers, and consumer goods due to its high clarity, excellent moisture barrier, and chemical resistance. Clear PET is favored in beverage bottles, cosmetic containers, and retail packaging for its superior strength, recyclability, and clarity. Your choice between Clear Polypropylene and Clear PET depends on the specific application requirements such as durability, transparency, and environmental considerations.

Choosing the Right Material: Polypropylene vs PET

Clear Polypropylene offers excellent chemical resistance and flexibility, making it ideal for packaging applications requiring durability and moisture barrier properties. Clear PET provides superior clarity, strength, and impact resistance, commonly used for food and beverage containers due to its recyclability and excellent gas barrier. Understanding Your product's requirements for transparency, durability, and environmental impact helps determine whether clear Polypropylene or PET is the more suitable material.

Clear Polypropylene vs Clear PET Infographic

libmatt.com

libmatt.com