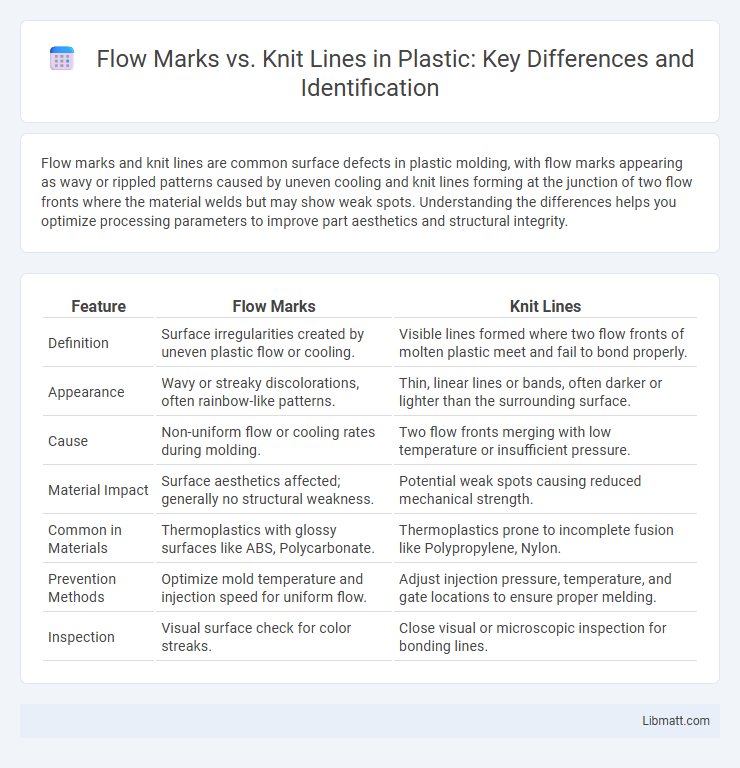

Flow marks and knit lines are common surface defects in plastic molding, with flow marks appearing as wavy or rippled patterns caused by uneven cooling and knit lines forming at the junction of two flow fronts where the material welds but may show weak spots. Understanding the differences helps you optimize processing parameters to improve part aesthetics and structural integrity.

Table of Comparison

| Feature | Flow Marks | Knit Lines |

|---|---|---|

| Definition | Surface irregularities created by uneven plastic flow or cooling. | Visible lines formed where two flow fronts of molten plastic meet and fail to bond properly. |

| Appearance | Wavy or streaky discolorations, often rainbow-like patterns. | Thin, linear lines or bands, often darker or lighter than the surrounding surface. |

| Cause | Non-uniform flow or cooling rates during molding. | Two flow fronts merging with low temperature or insufficient pressure. |

| Material Impact | Surface aesthetics affected; generally no structural weakness. | Potential weak spots causing reduced mechanical strength. |

| Common in Materials | Thermoplastics with glossy surfaces like ABS, Polycarbonate. | Thermoplastics prone to incomplete fusion like Polypropylene, Nylon. |

| Prevention Methods | Optimize mold temperature and injection speed for uniform flow. | Adjust injection pressure, temperature, and gate locations to ensure proper melding. |

| Inspection | Visual surface check for color streaks. | Close visual or microscopic inspection for bonding lines. |

Introduction to Flow Marks and Knit Lines

Flow marks and knit lines are common surface defects in injection molding caused by variations in the cooling and flow of molten plastic. Flow marks appear as wavy or rippled patterns on the part surface due to inconsistent filling speeds or temperature gradients. Knit lines, also known as weld lines, form where two or more flow fronts meet but fail to fuse properly, resulting in visible lines or weak spots in the molded part.

Understanding Flow Marks in Injection Molding

Flow marks in injection molding appear as surface blemishes caused by variations in the cooling rate or flow velocity of molten plastic within the mold cavity. They often result from inconsistent melt temperature or improper gate design leading to non-uniform flow front progression. Distinguishing flow marks from knit lines--which occur where two flow fronts converge and often exhibit weakness--helps optimize processing parameters for improved part aesthetics and structural integrity.

What Are Knit Lines?

Knit lines, also known as flow marks, are visible surface defects that occur when two or more polymer flow fronts meet during the injection molding or casting process but fail to fuse properly. These lines can weaken the structural integrity of the part and affect its aesthetic appearance, often indicating issues with mold design, processing conditions, or material properties. Understanding how knit lines form allows you to optimize manufacturing parameters to minimize their impact on your final product's quality.

Causes of Flow Marks

Flow marks occur due to uneven cooling and poor mold design that disrupts the polymer flow during injection molding. Factors such as variations in melt temperature, inconsistent injection speed, and insufficient venting lead to surface defects known as flow marks. These defects are visible as wavy or streaky patterns on the molded part, differing from knit lines, which form where two flow fronts meet.

Causes of Knit Lines

Knit lines form when two or more flow fronts of molten plastic converge but fail to fuse properly, typically caused by variations in mold temperature, low melt temperature, or insufficient injection speed. Flow marks, however, arise from inconsistent flow rates or sudden changes in mold geometry that disrupt uniform plastic flow. Understanding these causes helps in adjusting process parameters to minimize defects in injection-molded parts.

Visual Differences: Flow Marks vs Knit Lines

Flow marks appear as wavy or streaky surface imperfections caused by uneven cooling or flow of molten material during injection molding, often exhibiting a glossy or matte contrast against the surrounding area. Knit lines, also known as weld lines, manifest as visible seams or lines where two flow fronts meet and fail to fuse properly, typically forming a slightly raised or indented linear defect. Visually, flow marks disrupt the uniformity of the surface texture with irregular patterns, while knit lines present as distinct, straight or curved lines indicating a junction in the material flow.

Impact on Part Performance and Aesthetics

Flow marks and knit lines both affect part performance and aesthetics, yet their impacts differ significantly. Flow marks, caused by uneven cooling or improper fill patterns, can weaken structural integrity and create visible surface defects, while knit lines form where two flow fronts meet, potentially causing stress concentration points that reduce mechanical strength. Understanding how these defects influence Your injection-molded parts is crucial for optimizing both durability and visual quality.

Detection and Analysis Techniques

Flow marks and knit lines can be detected through visual inspection under proper lighting or using high-resolution imaging techniques such as microscopy and thermal imaging. Advanced methods like ultrasonic testing and dye penetrant analysis help reveal subsurface defects associated with flow marks, while infrared thermography and computerized simulation software assist in analyzing the formation and location of knit lines within molded parts. You can enhance defect detection accuracy by combining these non-destructive testing methods with digital image processing tools for more precise flow behavior analysis.

Solutions for Preventing Flow Marks and Knit Lines

To prevent flow marks and knit lines in injection molding, optimizing mold temperature and injection speed is essential to ensure uniform material flow and solidification. Implementing proper gate design and maintaining consistent packing pressure helps reduce surface imperfections and promotes seamless filling patterns. You can also enhance surface quality by using high-quality mold materials and applying surface coatings that improve flow characteristics.

Conclusion: Key Takeaways on Flow Marks vs Knit Lines

Flow marks appear as glossy or dull streaks caused by uneven cooling and flow patterns during injection molding, while knit lines form where two flow fronts meet and fail to bond properly. Both defects impact surface aesthetics and structural integrity, but flow marks primarily affect appearance, whereas knit lines pose a greater risk to part strength. Proper mold temperature control and optimized injection speed can reduce the occurrence of both flow marks and knit lines for higher-quality molded parts.

Flow marks vs knit lines Infographic

libmatt.com

libmatt.com