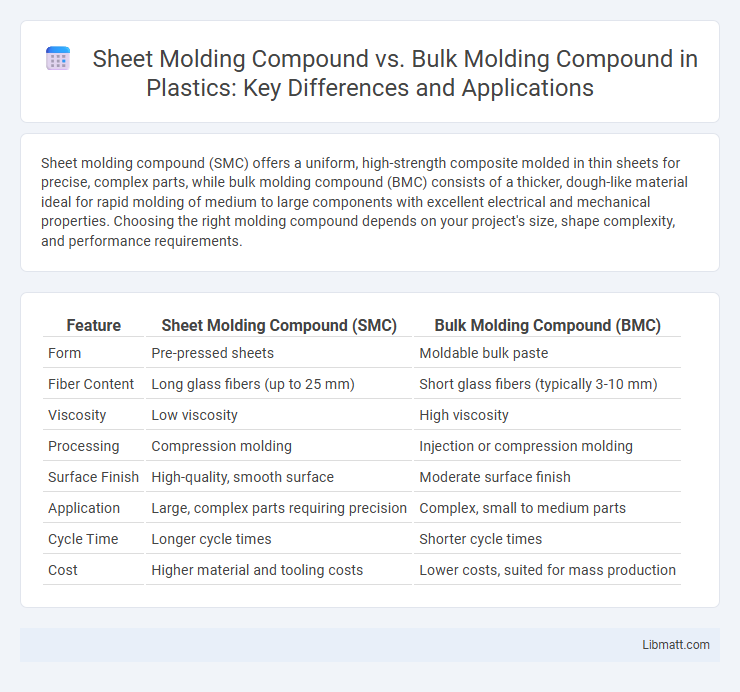

Sheet molding compound (SMC) offers a uniform, high-strength composite molded in thin sheets for precise, complex parts, while bulk molding compound (BMC) consists of a thicker, dough-like material ideal for rapid molding of medium to large components with excellent electrical and mechanical properties. Choosing the right molding compound depends on your project's size, shape complexity, and performance requirements.

Table of Comparison

| Feature | Sheet Molding Compound (SMC) | Bulk Molding Compound (BMC) |

|---|---|---|

| Form | Pre-pressed sheets | Moldable bulk paste |

| Fiber Content | Long glass fibers (up to 25 mm) | Short glass fibers (typically 3-10 mm) |

| Viscosity | Low viscosity | High viscosity |

| Processing | Compression molding | Injection or compression molding |

| Surface Finish | High-quality, smooth surface | Moderate surface finish |

| Application | Large, complex parts requiring precision | Complex, small to medium parts |

| Cycle Time | Longer cycle times | Shorter cycle times |

| Cost | Higher material and tooling costs | Lower costs, suited for mass production |

Introduction to SMC and BMC

Sheet Molded Compound (SMC) is a fiber-reinforced composite material combining polyester resin, chopped glass fibers, and fillers in a sheet form, known for its high strength-to-weight ratio and excellent surface finish. Bulk Molded Compound (BMC) consists of a similar mixture but is processed as a thick, dough-like mass suitable for injection molding, offering enhanced electrical insulation and intricate part molding capabilities. Both SMC and BMC are widely used in automotive, aerospace, and electrical industries due to their corrosion resistance, dimensional stability, and design flexibility.

Key Differences Between SMC and BMC

Sheet molding compound (SMC) and bulk molding compound (BMC) differ primarily in form and processing methods; SMC is a fiber-reinforced composite material supplied in sheets, while BMC is provided as a thick paste or dough-like substance. SMC offers superior surface finish and dimensional stability, making it suitable for large, complex parts with high aesthetic requirements, whereas BMC is ideal for smaller, more intricate components requiring high strength and electrical insulation. Your choice between SMC and BMC should consider factors such as part size, mechanical properties, and production efficiency to optimize performance and cost-effectiveness.

Raw Materials and Composition

Sheet molding compound (SMC) primarily consists of glass fibers, polyester resin, fillers, and a catalyst, pressed into thin sheets for ease of molding. Bulk molding compound (BMC) contains similar raw materials but differs in form, being a thick, dough-like mixture that allows for more complex shapes and thicker parts. Your choice between SMC and BMC depends on the required material properties, part complexity, and molding process constraints.

Processing Methods for SMC and BMC

Sheet molding compound (SMC) is processed by compression molding, where the material is pre-formed into flat sheets and then heated and pressed into molds to create complex shapes with high dimensional accuracy. Bulk molding compound (BMC) utilizes injection or compression molding, involving a shorter fiber reinforced resin paste that allows faster molding cycles and is ideal for intricate, small components. Your choice between SMC and BMC depends on the required surface finish, mechanical properties, and production volume.

Mechanical Properties Comparison

Sheet molding compound (SMC) offers superior mechanical properties compared to bulk molding compound (BMC), including higher tensile strength, better impact resistance, and improved flexural modulus due to its continuous fiber reinforcement and optimized resin matrix. SMC's uniform fiber distribution and controlled fiber length contribute to enhanced stiffness and dimensional stability, making it ideal for high-performance structural applications. Your choice between SMC and BMC should consider these mechanical performance differences to match specific load-bearing and durability requirements.

Typical Applications of SMC

Sheet molding compound (SMC) finds extensive use in automotive body panels, electrical components, and marine applications due to its superior surface finish and high strength-to-weight ratio. Its versatility allows for precise molding of complex shapes in industries such as aerospace, transportation, and construction. SMC's corrosion resistance and dimensional stability make it ideal for producing durable parts in outdoor and harsh environments.

Common Uses of BMC

Bulk molding compound (BMC) is extensively used in electrical housings, automotive parts, and consumer goods due to its excellent molding capabilities and consistent mechanical properties. The material's ability to be mass-produced in complex shapes makes it ideal for connectors, switch housings, and appliance components. BMC's flame retardant and insulating characteristics further support its application in the electronics and automotive industries.

Advantages and Disadvantages

Sheet molding compound (SMC) offers superior surface finish and dimensional stability, making it ideal for high-quality automotive and electrical applications. Bulk molding compound (BMC) provides faster molding cycle times and better flow characteristics, suitable for complex shapes and high-volume production, but may lack the surface smoothness of SMC. You should consider the trade-offs between SMC's enhanced aesthetic properties and BMC's cost-effectiveness and processing speed when selecting the appropriate molding compound for your project.

Cost and Efficiency Considerations

Sheet molding compound (SMC) typically offers higher efficiency in manufacturing due to its ability to produce complex shapes with consistent thickness and excellent surface finish, reducing post-processing costs. Bulk molding compound (BMC) generally has lower material costs and is suitable for high-volume production of smaller, less intricate parts, making it a cost-effective choice for your large-scale projects. Balancing your budget and production needs between SMC and BMC depends on the complexity of the part and required production speed.

Choosing Between SMC and BMC

Choosing between Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) depends on your specific application requirements, such as mechanical strength, surface finish, and mold complexity. SMC offers superior surface quality and is ideal for larger, more intricate parts, while BMC is suited for smaller components requiring high electrical insulation and uniform thickness. Understanding these distinctions ensures you select the composite material that best aligns with your manufacturing goals and performance expectations.

Sheet molding compound vs bulk molding compound Infographic

libmatt.com

libmatt.com