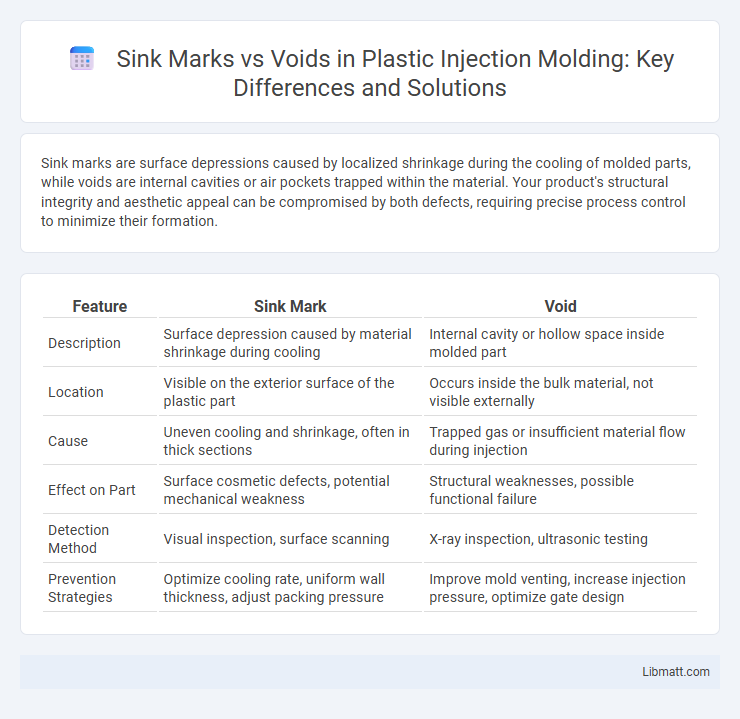

Sink marks are surface depressions caused by localized shrinkage during the cooling of molded parts, while voids are internal cavities or air pockets trapped within the material. Your product's structural integrity and aesthetic appeal can be compromised by both defects, requiring precise process control to minimize their formation.

Table of Comparison

| Feature | Sink Mark | Void |

|---|---|---|

| Description | Surface depression caused by material shrinkage during cooling | Internal cavity or hollow space inside molded part |

| Location | Visible on the exterior surface of the plastic part | Occurs inside the bulk material, not visible externally |

| Cause | Uneven cooling and shrinkage, often in thick sections | Trapped gas or insufficient material flow during injection |

| Effect on Part | Surface cosmetic defects, potential mechanical weakness | Structural weaknesses, possible functional failure |

| Detection Method | Visual inspection, surface scanning | X-ray inspection, ultrasonic testing |

| Prevention Strategies | Optimize cooling rate, uniform wall thickness, adjust packing pressure | Improve mold venting, increase injection pressure, optimize gate design |

Introduction to Sink Marks and Voids

Sink marks and voids are common defects in injection molded parts, impacting surface quality and structural integrity. Sink marks are shallow depressions caused by localized material shrinkage during cooling, while voids are internal cavities formed by trapped air or gas. Understanding these defects helps you optimize mold design and processing conditions to minimize part failures.

Defining Sink Marks in Plastics

Sink marks in plastics are surface depressions caused by the uneven cooling and shrinking of thicker sections in molded parts. These defects occur when the outer layer solidifies faster than the inner material, resulting in a visible indentation on the surface. Understanding the distinction between sink marks and voids helps you optimize mold design and processing parameters to minimize these imperfections.

Understanding Voids in Molding Processes

Voids in molding processes refer to internal cavities or empty spaces that form within a molded part due to incomplete material packing or gas entrapment, compromising structural integrity. Sink marks differ as surface depressions caused by localized shrinkage where thicker sections cool slower than surrounding material, affecting the exterior finish rather than internal strength. Understanding the formation of voids aids in optimizing injection parameters and mold design to prevent defects that impact mechanical performance.

Key Differences: Sink Marks vs Voids

Sink marks are surface depressions caused by localized material shrinkage during cooling, typically appearing over thicker sections, whereas voids are internal cavities or air pockets formed by trapped gas or insufficient packing pressure. Sink marks affect the external aesthetics without significantly compromising part integrity, while voids can weaken structural strength and lead to potential failure. Identifying and addressing sink marks usually involves optimizing cooling rates and mold design, whereas void prevention focuses on material flow and venting improvements.

Common Causes of Sink Marks

Sink marks commonly result from uneven cooling, where the surface solidifies faster than the material beneath, causing localized shrinkage. Inadequate packing pressure during molding fails to compensate for volumetric shrinkage, leading to surface depressions. Using thick sections or abrupt changes in part geometry often exacerbates sink mark formation by creating internal stress differentials during solidification.

Common Causes of Voids

Voids in injection molding typically arise from uneven cooling rates, inadequate packing pressure, or insufficient melt flow, leading to incomplete material filling or trapped air pockets. Unlike sink marks that form primarily due to volumetric shrinkage at thicker sections, voids represent hollow, air-filled cavities within the molded part. Identifying and optimizing mold design, gate locations, and processing parameters can effectively minimize void formation and improve part integrity.

Impact on Product Quality and Performance

Sink marks create surface depressions that can compromise the aesthetic quality and dimensional accuracy of molded products, potentially leading to weakened structural integrity. Voids, internal cavities trapped within the material, significantly reduce mechanical strength and can cause premature failure under stress or load. Both defects negatively affect product performance, but voids generally pose a more critical risk to durability and reliability.

Detection and Inspection Methods

Sink marks and voids are detected and inspected using non-destructive testing techniques like X-ray computed tomography (CT) and ultrasonic testing, which provide detailed internal imaging to identify subsurface defects. Visual inspection under controlled lighting can reveal surface depressions characteristic of sink marks, while voids are often confirmed through cross-sectional analysis or destructive testing methods such as microscopy after sample sectioning. Advanced methods like laser scanning and 3D profilometry enhance detection accuracy by quantifying dimensional anomalies and internal cavity volumes in molded components.

Prevention and Minimization Strategies

Sink mark prevention involves optimizing mold temperature, injection pressure, and cooling time to ensure uniform material flow and reduce surface depressions. Void minimization requires controlling gate design, material viscosity, and packing pressure to avoid internal air pockets and enhance structural integrity. Your molding process benefits from precise parameter adjustments and material selection to effectively reduce both sink marks and voids.

Conclusion: Choosing the Right Solution

Sink marks are surface depressions caused by plastic material shrinkage during cooling, whereas voids are internal cavities resulting from trapped air or inconsistent material flow. Understanding these distinctions is crucial for optimizing mold design and processing conditions to prevent defects in your molded parts. Selecting the right solution depends on analyzing part geometry and material behavior to apply targeted cooling, packing pressure, or venting techniques effectively.

Sink mark vs void Infographic

libmatt.com

libmatt.com