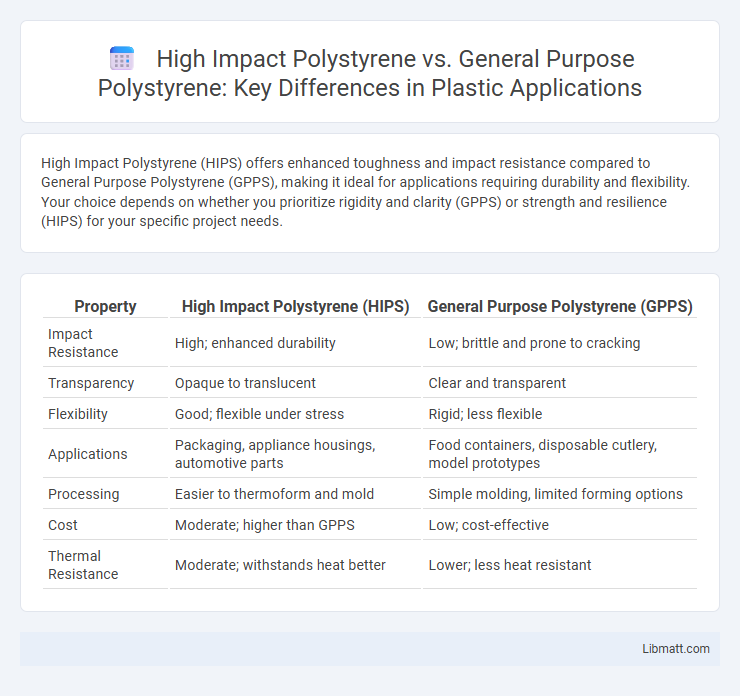

High Impact Polystyrene (HIPS) offers enhanced toughness and impact resistance compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring durability and flexibility. Your choice depends on whether you prioritize rigidity and clarity (GPPS) or strength and resilience (HIPS) for your specific project needs.

Table of Comparison

| Property | High Impact Polystyrene (HIPS) | General Purpose Polystyrene (GPPS) |

|---|---|---|

| Impact Resistance | High; enhanced durability | Low; brittle and prone to cracking |

| Transparency | Opaque to translucent | Clear and transparent |

| Flexibility | Good; flexible under stress | Rigid; less flexible |

| Applications | Packaging, appliance housings, automotive parts | Food containers, disposable cutlery, model prototypes |

| Processing | Easier to thermoform and mold | Simple molding, limited forming options |

| Cost | Moderate; higher than GPPS | Low; cost-effective |

| Thermal Resistance | Moderate; withstands heat better | Lower; less heat resistant |

Introduction to Polystyrene: Types and Uses

High Impact Polystyrene (HIPS) offers enhanced durability and impact resistance compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring toughness, such as appliance housings and food packaging. GPPS, characterized by its clarity and rigidity, is widely used in disposable cutlery, CD cases, and model kits where aesthetic appeal and surface finish are crucial. Both types belong to the polystyrene family, a versatile thermoplastic polymer extensively utilized in packaging, consumer goods, and industrial components for its moldability and cost-effectiveness.

What is High Impact Polystyrene (HIPS)?

High Impact Polystyrene (HIPS) is a versatile thermoplastic polymer known for its enhanced impact resistance compared to General Purpose Polystyrene (GPPS), achieved by the addition of rubber particles during production. This modification provides HIPS with improved durability and toughness, making it ideal for applications that require higher mechanical strength such as packaging, automotive parts, and consumer electronics housings. Your choice between HIPS and GPPS should consider the balance between impact resistance and surface finish, as HIPS offers greater toughness but slightly less clarity and stiffness than GPPS.

Understanding General Purpose Polystyrene (GPPS)

General Purpose Polystyrene (GPPS) is a clear, rigid, and brittle thermoplastic commonly used for packaging, disposable cutlery, and model-making due to its excellent clarity and ease of processing. Unlike High Impact Polystyrene (HIPS), GPPS lacks the rubber component that enhances impact resistance, making it less suitable for applications requiring durability or shock absorption. Your choice between GPPS and HIPS depends on whether clarity and surface finish or toughness and impact resistance are the primary requirements for your project.

Key Differences Between HIPS and GPPS

High Impact Polystyrene (HIPS) differs from General Purpose Polystyrene (GPPS) primarily in its toughness and impact resistance, with HIPS incorporating rubber particles that enhance durability against physical stress. GPPS offers superior clarity and stiffness but lacks the flexibility and impact resistance found in HIPS, making it more brittle under load. These differences make HIPS ideal for applications requiring durability, such as appliance parts, while GPPS is preferred for packaging and products needing optical clarity.

Mechanical Properties: Strength and Durability

High Impact Polystyrene (HIPS) offers superior strength and durability compared to General Purpose Polystyrene (GPPS), with enhanced impact resistance due to its rubber-modified polymer structure. GPPS exhibits higher rigidity but is more brittle, making it less suitable for applications requiring toughness and prolonged mechanical stress endurance. Your choice of polystyrene should consider HIPS for products demanding robust mechanical performance and resistance to cracking under impact.

Applications: Where HIPS and GPPS Excel

High Impact Polystyrene (HIPS) excels in applications requiring enhanced impact resistance, such as packaging for electronics, automotive parts, and appliance housings, due to its toughness and durability. General Purpose Polystyrene (GPPS) is preferred for products demanding clarity and rigidity, including food containers, disposable cutlery, and laboratory ware, as it provides excellent optical properties and stiffness. Both materials serve distinct roles in manufacturing, with HIPS favored for impact-heavy uses and GPPS for applications prioritizing transparency and dimensional stability.

Processing and Fabrication Methods

High Impact Polystyrene (HIPS) offers enhanced impact resistance and is commonly processed through injection molding, extrusion, and thermoforming, enabling complex shapes with durability in applications like automotive parts and packaging. General Purpose Polystyrene (GPPS) is primarily processed by injection molding and extrusion, favoring clarity and rigidity but with lower impact strength, making it suitable for disposable cutlery and food containers. The fabrication methods for HIPS often require temperature control and mold design optimization to maximize toughness, while GPPS benefits from simpler processing parameters to maintain its transparent and brittle nature.

Cost Analysis: HIPS vs GPPS

High Impact Polystyrene (HIPS) typically incurs higher production costs compared to General Purpose Polystyrene (GPPS) due to the rubber modification process enhancing its impact resistance. GPPS is more cost-effective for applications requiring basic rigidity without the need for significant durability, making it suitable for low-stress products. Evaluating the balance between upfront material costs and performance requirements is crucial for selecting between HIPS and GPPS in budget-conscious manufacturing.

Environmental Impact and Recycling

High Impact Polystyrene (HIPS) and General Purpose Polystyrene (GPPS) differ in environmental impact due to their composition and end-of-life recyclability. HIPS, containing rubber additives, poses greater challenges in recycling processes compared to GPPS, which is more easily recyclable and less energy-intensive to process. Both materials contribute to plastic waste concerns, but advancements in recycling technologies and increased sorting efficiency aim to improve recovery rates and reduce their environmental footprint.

Choosing the Right Polystyrene for Your Project

High Impact Polystyrene (HIPS) offers superior impact resistance and durability compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring toughness and flexibility, such as packaging and consumer goods. GPPS provides excellent clarity and rigidity, suitable for products where transparency and form stability are critical, including food containers and display cases. Selecting the right polystyrene depends on balancing mechanical strength with aesthetic requirements, ensuring project-specific performance and cost-effectiveness.

High Impact Polystyrene vs General Purpose Polystyrene Infographic

libmatt.com

libmatt.com