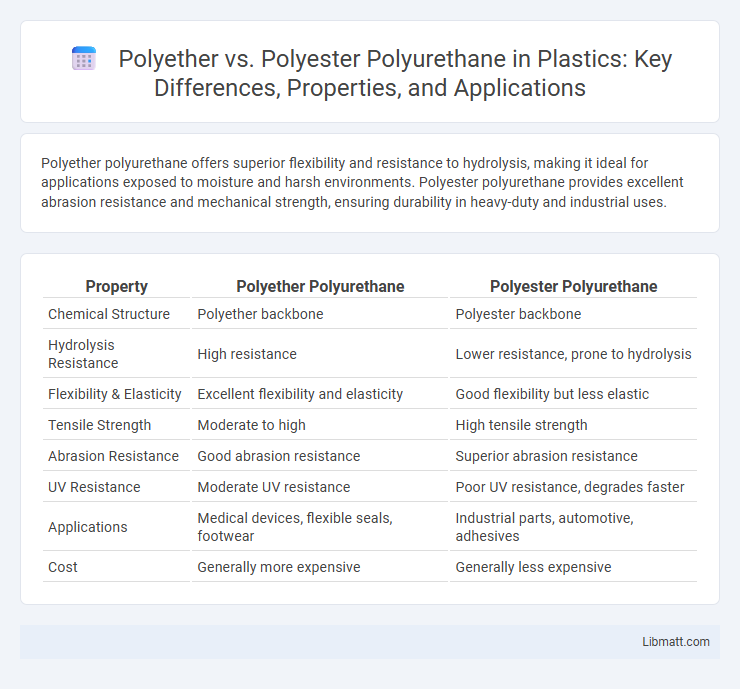

Polyether polyurethane offers superior flexibility and resistance to hydrolysis, making it ideal for applications exposed to moisture and harsh environments. Polyester polyurethane provides excellent abrasion resistance and mechanical strength, ensuring durability in heavy-duty and industrial uses.

Table of Comparison

| Property | Polyether Polyurethane | Polyester Polyurethane |

|---|---|---|

| Chemical Structure | Polyether backbone | Polyester backbone |

| Hydrolysis Resistance | High resistance | Lower resistance, prone to hydrolysis |

| Flexibility & Elasticity | Excellent flexibility and elasticity | Good flexibility but less elastic |

| Tensile Strength | Moderate to high | High tensile strength |

| Abrasion Resistance | Good abrasion resistance | Superior abrasion resistance |

| UV Resistance | Moderate UV resistance | Poor UV resistance, degrades faster |

| Applications | Medical devices, flexible seals, footwear | Industrial parts, automotive, adhesives |

| Cost | Generally more expensive | Generally less expensive |

Introduction to Polyurethane Types

Polyurethane types are primarily classified into polyether and polyester categories based on their backbone chemistry, influencing key properties like flexibility, moisture resistance, and durability. Polyether polyurethane offers excellent hydrolytic stability and flexibility, making it ideal for applications requiring resilience in wet environments, whereas polyester polyurethane excels in abrasion resistance and mechanical strength, suitable for heavy-duty uses. Your choice between polyether and polyester polyurethane depends on the specific performance requirements, including exposure conditions and longevity needs.

What is Polyether Polyurethane?

Polyether polyurethane is a type of flexible polymer made from polyether polyols, offering excellent hydrolytic stability and resistance to water and chemicals, making it ideal for applications requiring durability in moist environments. Its molecular structure provides superior elasticity, low-temperature flexibility, and resistance to abrasion compared to polyester polyurethane. You can rely on polyether polyurethane in medical devices, foam cushioning, and sealants where resilience and longevity are critical.

What is Polyester Polyurethane?

Polyester polyurethane is a type of polyurethane elastomer derived from polyester polyols, known for its excellent abrasion resistance, high tensile strength, and chemical stability. It exhibits superior durability in harsh environments, making it ideal for industrial applications such as conveyor belts, seals, and gaskets. Compared to polyether polyurethane, polyester polyurethane offers enhanced resistance to oils, solvents, and heat, providing longer service life in demanding conditions.

Chemical Structure Comparison

Polyether polyurethane contains repeating units derived from polyether chains, characterized by ether linkages (-C-O-C-) that impart flexibility and hydrolytic stability. Polyester polyurethane features ester linkages (-COO-) within its backbone, resulting in increased rigidity and susceptibility to hydrolysis. The chemical structure differences influence the polymers' mechanical properties, with polyether-based polyurethanes generally exhibiting better water resistance and polyester-based variants offering superior tensile strength.

Mechanical Properties: Durability & Strength

Polyether polyurethane offers superior flexibility and hydrolytic stability, making it highly durable in wet environments, while polyester polyurethane provides greater tensile strength and abrasion resistance, ideal for applications requiring enhanced mechanical strength. Your choice depends on whether durability in moisture or overall tensile performance is more critical for the intended use, as polyether excels in elasticity and polyester in load-bearing capacity. Both materials exhibit strong mechanical properties, but polyester polyurethane tends to deliver higher durability under mechanical stress, while polyether polyurethane resists degradation better over time in harsh conditions.

Resistance to Hydrolysis and Chemical Exposure

Polyether polyurethane exhibits superior resistance to hydrolysis, making it ideal for applications involving prolonged exposure to water or moisture. In contrast, polyester polyurethane, while offering excellent mechanical strength and abrasion resistance, is more susceptible to hydrolytic degradation and chemical attack from acids or bases. Your choice between polyether and polyester polyurethane should consider the specific environmental conditions and chemical exposure to ensure optimal durability and performance.

Flexibility and Elasticity Differences

Polyether polyurethane offers superior flexibility and elasticity compared to polyester polyurethane, making it ideal for applications requiring prolonged stretch and recovery without deformation. Polyester polyurethane provides greater tensile strength but tends to be less elastic and more rigid over time due to its crystalline structure. Your choice depends on whether durability with stretch or strength with stiffness better suits your material needs.

Common Applications of Polyether vs Polyester Polyurethane

Polyether polyurethane is commonly used in flexible foam products, such as mattresses, furniture cushions, and automotive seating, due to its excellent hydrolytic stability and resistance to moisture. Polyester polyurethane finds widespread application in coatings, adhesives, and elastomers where enhanced mechanical strength, chemical resistance, and durability are critical. Both types serve critical roles in footwear, sealants, and synthetic leather production, with polyester variants preferred in environments exposed to oils and solvents.

Cost and Environmental Considerations

Polyether polyurethane generally costs more than polyester polyurethane due to its superior hydrolytic stability and flexibility, which can reduce long-term maintenance expenses. Polyester polyurethane is typically less expensive initially but may incur higher replacement and environmental costs because it degrades faster and releases harmful chemicals during breakdown. Your choice should weigh the upfront investment against environmental impact, favoring polyether polyurethane for durability and polyester polyurethane for lower immediate costs.

Choosing the Right Polyurethane for Your Needs

Polyether polyurethane offers superior hydrolysis resistance and flexibility, making it ideal for applications exposed to moisture and dynamic stresses. Polyester polyurethane provides excellent abrasion resistance and tensile strength, suited for demanding mechanical and industrial environments. Selecting the right polyurethane depends on factors like exposure to water, required durability, and mechanical load, ensuring optimal performance and longevity.

Polyether vs Polyester Polyurethane Infographic

libmatt.com

libmatt.com