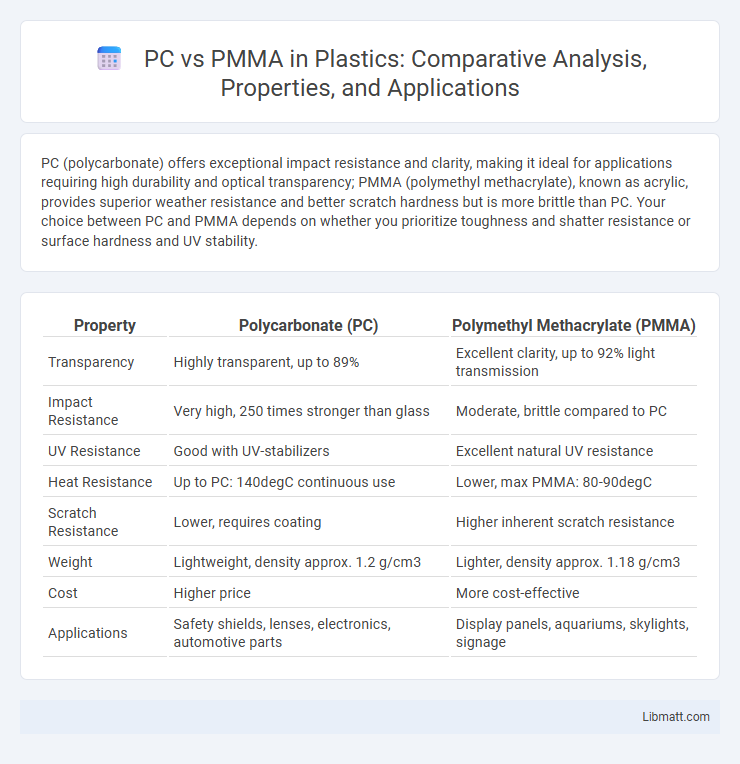

PC (polycarbonate) offers exceptional impact resistance and clarity, making it ideal for applications requiring high durability and optical transparency; PMMA (polymethyl methacrylate), known as acrylic, provides superior weather resistance and better scratch hardness but is more brittle than PC. Your choice between PC and PMMA depends on whether you prioritize toughness and shatter resistance or surface hardness and UV stability.

Table of Comparison

| Property | Polycarbonate (PC) | Polymethyl Methacrylate (PMMA) |

|---|---|---|

| Transparency | Highly transparent, up to 89% | Excellent clarity, up to 92% light transmission |

| Impact Resistance | Very high, 250 times stronger than glass | Moderate, brittle compared to PC |

| UV Resistance | Good with UV-stabilizers | Excellent natural UV resistance |

| Heat Resistance | Up to PC: 140degC continuous use | Lower, max PMMA: 80-90degC |

| Scratch Resistance | Lower, requires coating | Higher inherent scratch resistance |

| Weight | Lightweight, density approx. 1.2 g/cm3 | Lighter, density approx. 1.18 g/cm3 |

| Cost | Higher price | More cost-effective |

| Applications | Safety shields, lenses, electronics, automotive parts | Display panels, aquariums, skylights, signage |

Introduction to PC and PMMA

Polycarbonate (PC) is a durable, impact-resistant thermoplastic known for its high optical clarity and heat resistance, commonly used in applications requiring strength and transparency such as eyewear lenses and protective gear. Polymethyl methacrylate (PMMA), also known as acrylic, is a lightweight, transparent plastic valued for its excellent light transmittance and weather resistance, often utilized in signage, aquariums, and automotive parts. Understanding the distinct properties of PC and PMMA helps you choose the best material for your project's specific durability and visual quality requirements.

Chemical Composition and Structure

Polycarbonate (PC) is an amorphous thermoplastic polymer composed of bisphenol A and phosgene, characterized by a carbonate group (-O-(C=O)-O-) linking its repeating units. Polymethyl methacrylate (PMMA) is a synthetic resin derived from the polymerization of methyl methacrylate monomers, featuring a linear structure with ester functional groups (-COOCH3) attached to the polymer backbone. Understanding the chemical composition and structure of PC and PMMA helps you select the right material based on thermal stability, transparency, and mechanical properties.

Optical Properties Comparison

Polycarbonate (PC) offers superior impact resistance and excellent optical clarity with a light transmittance rate of approximately 88%, making it ideal for applications requiring durability and transparency. Polymethyl methacrylate (PMMA) provides higher light transmittance at around 92%, delivering outstanding clarity and UV resistance but with lower impact strength compared to PC. Your choice between PC and PMMA should consider the trade-off between optical clarity and impact resistance based on the specific requirements of your project.

Mechanical Strength and Durability

Polycarbonate (PC) offers superior mechanical strength and impact resistance compared to Polymethyl Methacrylate (PMMA), making it ideal for applications requiring high durability and toughness. PC exhibits excellent resistance to cracking and shattering under stress, while PMMA provides good rigidity but is more prone to brittleness and deformation over time. Your choice between PC and PMMA should consider the required strength and longevity for the intended use, with PC favored in demanding environments and PMMA suitable for less intensive applications.

Thermal Resistance and Stability

Polycarbonate (PC) exhibits superior thermal resistance and stability compared to polymethyl methacrylate (PMMA), with a higher glass transition temperature around 147degC versus PMMA's 105degC. PC maintains structural integrity under elevated temperatures and resists deformation, making it suitable for high-heat applications. PMMA, while offering good clarity, tends to soften and deform more quickly under heat, limiting its use in environments requiring sustained thermal performance.

Impact Resistance and Safety

PC (polycarbonate) offers superior impact resistance compared to PMMA (acrylic), making it ideal for applications demanding high safety standards. Its ability to absorb and withstand significant force reduces the risk of shattering, protecting users from hazardous sharp fragments. Your choice of PC ensures enhanced durability and safety in environments prone to impact stress.

Ease of Fabrication and Machining

PC (polycarbonate) offers superior ease of fabrication and machining compared to PMMA (polymethyl methacrylate) due to its higher impact resistance and flexibility, allowing for more extensive cutting, drilling, and thermoforming without cracking. PMMA is more brittle, requiring greater care during machining to avoid chipping, but it provides a smoother surface finish suitable for optical clarity applications. For Your projects needing complex shapes or durability, PC's versatility in fabrication can reduce production time and improve part performance.

Cost and Availability

Polycarbonate (PC) is generally more expensive than polymethyl methacrylate (PMMA) due to its superior impact resistance and durability, making it a premium choice for demanding applications. PMMA offers more cost-effective solutions with widespread availability, especially in standard sheet sizes for signage and glazing. Both materials are readily available globally, but PMMA's lower price point and ease of fabrication often make it the preferred option for budget-conscious projects.

Typical Applications and Use Cases

Polycarbonate (PC) is widely used in safety equipment, automotive parts, and electronic devices due to its high impact resistance and transparency. Polymethyl methacrylate (PMMA), known for its excellent optical clarity and weather resistance, is commonly employed in signage, displays, and glazing applications. Both materials serve in protective and decorative roles, with PC favored for durability and PMMA for aesthetic appeal.

Environmental Impact and Recyclability

Polycarbonate (PC) and polymethyl methacrylate (PMMA) differ significantly in environmental impact and recyclability. PC is more energy-intensive to produce but offers better durability and higher potential for mechanical recycling, reducing landfill waste over time. PMMA has lower production emissions but is more challenging to recycle due to limited facilities and its susceptibility to degradation during recycling, leading to increased environmental burdens.

PC vs PMMA Infographic

libmatt.com

libmatt.com