Thermoforming shapes plastic sheets by heating and molding them over a specific form, offering cost-effective solutions for large parts with lower tooling expenses. Injection molding injects molten plastic into precise molds, enabling high-volume production of complex, durable components with tight tolerances ideal for your detailed manufacturing needs.

Table of Comparison

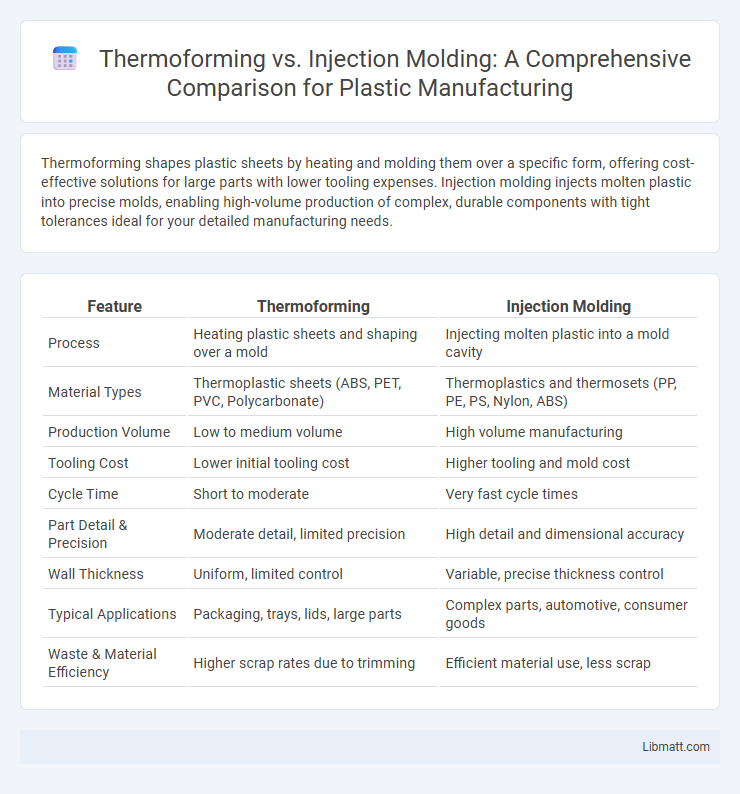

| Feature | Thermoforming | Injection Molding |

|---|---|---|

| Process | Heating plastic sheets and shaping over a mold | Injecting molten plastic into a mold cavity |

| Material Types | Thermoplastic sheets (ABS, PET, PVC, Polycarbonate) | Thermoplastics and thermosets (PP, PE, PS, Nylon, ABS) |

| Production Volume | Low to medium volume | High volume manufacturing |

| Tooling Cost | Lower initial tooling cost | Higher tooling and mold cost |

| Cycle Time | Short to moderate | Very fast cycle times |

| Part Detail & Precision | Moderate detail, limited precision | High detail and dimensional accuracy |

| Wall Thickness | Uniform, limited control | Variable, precise thickness control |

| Typical Applications | Packaging, trays, lids, large parts | Complex parts, automotive, consumer goods |

| Waste & Material Efficiency | Higher scrap rates due to trimming | Efficient material use, less scrap |

Overview of Thermoforming and Injection Molding

Thermoforming involves heating a plastic sheet until pliable and then shaping it over a mold, ideal for large parts with lower production volumes. Injection molding injects molten plastic into a mold cavity, producing high-precision, complex parts efficiently in large quantities. Both methods offer distinct advantages depending on factors like production scale, part complexity, and material usage.

Core Process Differences

Thermoforming involves heating a plastic sheet until pliable, then shaping it over a mold using vacuum or pressure, making it ideal for large parts with shallow depths. Injection molding injects molten plastic into a closed, precision-engineered mold to create complex, detailed parts with tight tolerances. Your choice depends on production volume, design complexity, and material thickness requirements.

Material Compatibility and Selection

Thermoforming excels in processing thin-gauge plastics like PET, PVC, and ABS, making it ideal for packaging and lightweight applications, whereas injection molding accommodates a broader range of materials including thermoplastics such as polyethylene, polypropylene, and polycarbonate for complex, high-precision parts. Material compatibility in thermoforming is often limited by heat sensitivity and sheet form, while injection molding supports materials with varying viscosities and additives for enhanced mechanical properties. Selecting the right process depends on the required material characteristics, part complexity, and production volume, with injection molding offering greater versatility in material selection and performance attributes.

Design Flexibility and Limitations

Thermoforming offers greater design flexibility for large parts with simple geometries, enabling quick modifications and lower tooling costs compared to injection molding. Injection molding excels in producing complex, highly detailed components with tight tolerances and intricate features that thermoforming cannot achieve. However, thermoforming is limited by thinner walls and less precision, while injection molding requires higher upfront tooling investment and longer setup times.

Production Speed and Cycle Times

Thermoforming offers faster production speeds with shorter cycle times, making it ideal for low to medium volume runs and rapid prototyping. Injection molding features longer cycle times due to cooling and solidification phases but supports high-volume manufacturing with consistent precision. Your choice depends on balancing speed requirements with production scale and part complexity.

Cost Comparison: Tooling and Per-Part Expenses

Thermoforming typically involves lower initial tooling costs due to simpler molds compared to the high-precision, durable molds required for injection molding. Per-part expenses in thermoforming are usually higher for small production runs because of slower cycle times, while injection molding offers lower per-part costs at high volumes due to faster production speed and material efficiency. Injection molding is more cost-effective for large-scale manufacturing, whereas thermoforming suits lower volume or prototyping with budget constraints on tooling.

Typical Applications and Industries

Thermoforming is widely used in packaging industries, automotive interiors, and medical device components, offering cost-effective solutions for large parts with intricate shapes. Injection molding excels in producing high-precision, complex parts for electronics, consumer goods, and aerospace industries, where durability and tight tolerances are critical. Your choice between these methods depends on the production volume and detail requirements of your specific application.

Environmental Impact and Material Waste

Thermoforming generates less material waste compared to injection molding by utilizing sheet plastics that can be trimmed with minimal excess, making it more environmentally efficient for large, simple shapes. Injection molding, while precise and capable of producing complex parts, often results in higher material scrap due to runner systems and excess plastic, increasing environmental impact. Your choice between these methods should consider the balance between design complexity and sustainability goals to minimize waste and energy use.

Quality, Precision, and Tolerances

Thermoforming offers moderate precision with quality suitable for larger parts and simpler geometries, maintaining tolerances typically around +-0.030 inches. Injection molding provides superior quality and high precision, delivering tight tolerances as low as +-0.001 inches, ideal for complex shapes and intricate details. Your choice depends on the required detail level and dimensional accuracy, with injection molding excelling in consistency and repeatability.

Choosing the Right Process for Your Project

Thermoforming is ideal for producing large, thin-walled parts with moderate detail, offering lower tooling costs and faster turnaround for small to medium production runs. Injection molding delivers higher precision, complex geometries, and durability, making it suitable for high-volume manufacturing despite higher initial mold investment. Assess your project's budget, production volume, and part complexity to determine whether thermoforming or injection molding best meets your manufacturing needs.

Thermoforming vs Injection Molding Infographic

libmatt.com

libmatt.com