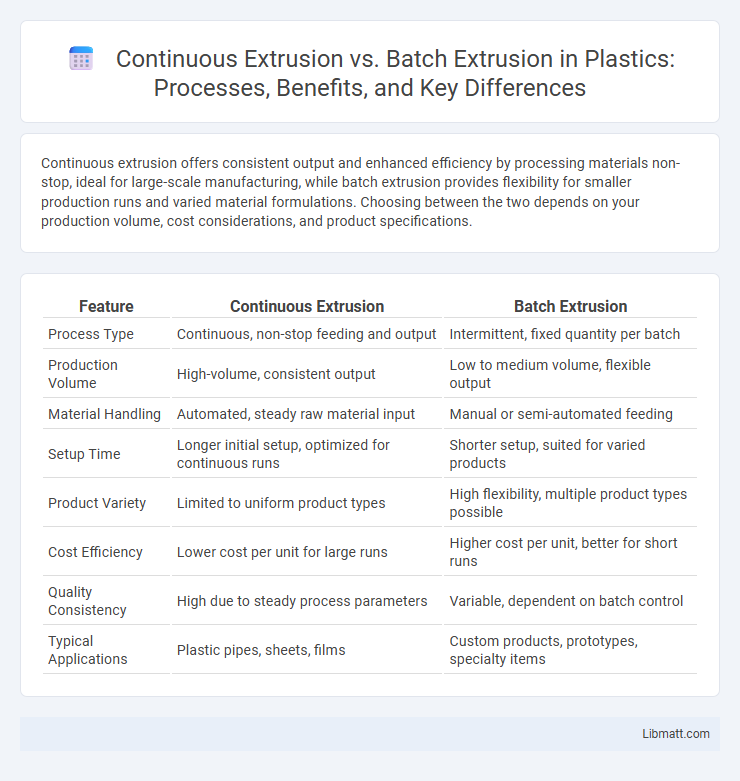

Continuous extrusion offers consistent output and enhanced efficiency by processing materials non-stop, ideal for large-scale manufacturing, while batch extrusion provides flexibility for smaller production runs and varied material formulations. Choosing between the two depends on your production volume, cost considerations, and product specifications.

Table of Comparison

| Feature | Continuous Extrusion | Batch Extrusion |

|---|---|---|

| Process Type | Continuous, non-stop feeding and output | Intermittent, fixed quantity per batch |

| Production Volume | High-volume, consistent output | Low to medium volume, flexible output |

| Material Handling | Automated, steady raw material input | Manual or semi-automated feeding |

| Setup Time | Longer initial setup, optimized for continuous runs | Shorter setup, suited for varied products |

| Product Variety | Limited to uniform product types | High flexibility, multiple product types possible |

| Cost Efficiency | Lower cost per unit for large runs | Higher cost per unit, better for short runs |

| Quality Consistency | High due to steady process parameters | Variable, dependent on batch control |

| Typical Applications | Plastic pipes, sheets, films | Custom products, prototypes, specialty items |

Introduction to Extrusion Methods

Continuous extrusion involves a steady, uninterrupted process where raw materials are fed consistently, producing uniform products ideal for high-volume manufacturing. Batch extrusion processes materials in discrete quantities, allowing greater flexibility and control over product variations but often resulting in longer production cycles. Understanding these extrusion methods helps optimize Your manufacturing approach based on efficiency, product consistency, and customization needs.

What is Continuous Extrusion?

Continuous extrusion is a high-efficiency manufacturing process where raw material is fed continuously into an extruder, producing a consistent, uniform profile without interruption. This method enhances productivity by maintaining steady operation and minimizing material waste compared to batch extrusion, which processes material in discrete, interrupted cycles. Your manufacturing line can benefit from continuous extrusion by achieving faster production rates and improved product quality.

What is Batch Extrusion?

Batch extrusion is a manufacturing process where material is fed and processed in discrete quantities or batches, allowing for greater control over product variations and customization. This method contrasts with continuous extrusion, where the material is processed without interruption, making batch extrusion ideal for smaller production runs and specialized applications. Your choice of batch extrusion can optimize flexibility and precision in producing complex or diverse product profiles.

Key Differences Between Continuous and Batch Extrusion

Continuous extrusion offers a steady, uninterrupted production process ideal for high-volume manufacturing, while batch extrusion processes discrete quantities, suitable for smaller runs or custom orders. Continuous extrusion ensures consistent material flow and uniform product quality, whereas batch extrusion allows for greater flexibility in material changes and product variations. The key differences lie in production scale, process stability, and adaptability to product specifications.

Process Flow Comparison

Continuous extrusion involves a steady, uninterrupted process where raw materials are continuously fed, melted, and shaped into the desired profile, allowing for consistent product quality and high production rates. Batch extrusion processes discrete quantities of material, undergoing separate steps of feeding, melting, and shaping, which allows for easier customization but results in slower throughput and potential variability between batches. The continuous flow in continuous extrusion minimizes downtime and facilitates scalability, whereas batch extrusion offers flexibility for producing small volumes or experimental runs with diverse material formulations.

Advantages of Continuous Extrusion

Continuous extrusion offers higher production efficiency by enabling uninterrupted material processing and consistent output quality, reducing downtime compared to batch extrusion. This method provides better control over product uniformity and dimensional accuracy, which is essential for industries requiring precise specifications. Energy consumption is typically lower in continuous extrusion due to streamlined operations, resulting in cost savings and increased sustainability.

Benefits of Batch Extrusion

Batch extrusion offers precise control over product formulation and processing parameters, making it ideal for small to medium production runs where customization is crucial. The ability to easily change materials and adjust operating conditions enhances flexibility and reduces downtime between batches. This method also minimizes material waste and enables thorough quality inspection for each batch, ensuring consistent product standards and compliance with specific industry requirements.

Challenges and Limitations of Each Method

Continuous extrusion offers high throughput but faces challenges in maintaining consistent product quality due to limited real-time control over process variables. Batch extrusion provides better flexibility and customization but is limited by lower efficiency and increased downtime for cleaning and setup changes. Both methods contend with material degradation risks, where continuous extrusion risks uneven heat distribution and batch extrusion suffers from thermal cycling effects.

Industry Applications and Suitability

Continuous extrusion excels in industries requiring high-volume production and consistent product quality, such as automotive, construction, and packaging sectors. Batch extrusion suits specialized applications like medical devices or custom profiles where flexibility and small runs are critical. Equipment selection depends on production scale, material characteristics, and required precision for industry-specific needs.

Selecting the Right Extrusion Process for Your Needs

Choosing between continuous extrusion and batch extrusion depends on production volume, material type, and precision requirements. Continuous extrusion is ideal for high-volume manufacturing with consistent material flow and minimal downtime, while batch extrusion offers greater flexibility for small-scale runs or specialty materials. Your decision should align with efficiency goals, setup costs, and the specific properties of the product you need to create.

Continuous Extrusion vs Batch Extrusion Infographic

libmatt.com

libmatt.com