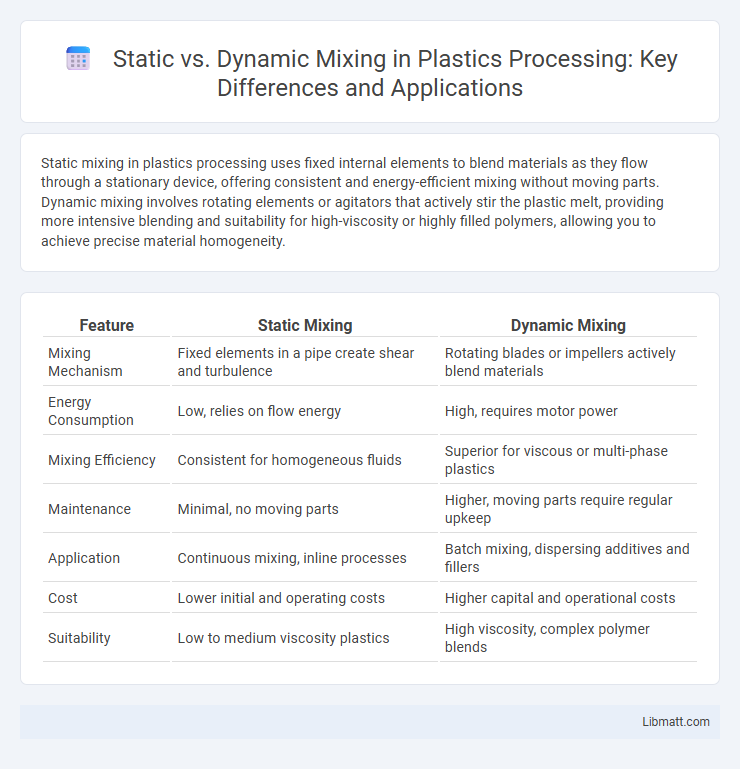

Static mixing in plastics processing uses fixed internal elements to blend materials as they flow through a stationary device, offering consistent and energy-efficient mixing without moving parts. Dynamic mixing involves rotating elements or agitators that actively stir the plastic melt, providing more intensive blending and suitability for high-viscosity or highly filled polymers, allowing you to achieve precise material homogeneity.

Table of Comparison

| Feature | Static Mixing | Dynamic Mixing |

|---|---|---|

| Mixing Mechanism | Fixed elements in a pipe create shear and turbulence | Rotating blades or impellers actively blend materials |

| Energy Consumption | Low, relies on flow energy | High, requires motor power |

| Mixing Efficiency | Consistent for homogeneous fluids | Superior for viscous or multi-phase plastics |

| Maintenance | Minimal, no moving parts | Higher, moving parts require regular upkeep |

| Application | Continuous mixing, inline processes | Batch mixing, dispersing additives and fillers |

| Cost | Lower initial and operating costs | Higher capital and operational costs |

| Suitability | Low to medium viscosity plastics | High viscosity, complex polymer blends |

Introduction to Mixing in Plastics Processing

Mixing in plastics processing is essential for achieving uniform dispersion of additives, colorants, and polymers to enhance material properties. Static mixers use fixed geometric elements to create turbulence and blend materials without moving parts, offering energy efficiency and low maintenance. Dynamic mixers employ rotating blades or screws to actively shear and combine components, providing faster and more thorough mixing for complex formulations.

What is Static Mixing?

Static mixing in plastics processing involves blending materials using fixed internal elements within a pipe or chamber, creating turbulent flow without moving parts. This method ensures consistent dispersion of additives or polymers by leveraging the flow dynamics, which improves product uniformity and reduces processing time. Your production benefits from lower energy consumption and minimal maintenance compared to dynamic mixing alternatives.

What is Dynamic Mixing?

Dynamic mixing in plastics processing involves actively blending materials using moving parts such as rotors or paddles to ensure uniform distribution of additives and polymers. This method enhances the homogeneity and consistency of the final plastic product by continuously agitating the mixture during processing. Your production benefits from improved dispersion and reduced cycle times compared to static mixing techniques.

Key Differences Between Static and Dynamic Mixing

Static mixing relies on stationary elements within a pipe to blend materials as they flow, promoting consistent mixing without moving parts. Dynamic mixing uses rotating or oscillating components that provide intensive shear and turbulence for faster and more thorough blending. Your choice depends on factors like viscosity, flow rate, and desired mixing efficiency, with static mixers offering lower maintenance and dynamic mixers delivering higher energy input.

Advantages of Static Mixing in Plastics Processing

Static mixing in plastics processing offers consistent and efficient blending of polymers without moving parts, reducing maintenance and operational costs. Enhanced flow uniformity achieved through engineered mixing elements improves product quality by minimizing material inconsistencies and defects. Energy-efficient operation with minimal pressure drop contributes to sustainable manufacturing and lower overall production expenses.

Advantages of Dynamic Mixing in Plastics Processing

Dynamic mixing in plastics processing offers enhanced shear forces that ensure a more uniform distribution of additives and fillers compared to static mixing. This improved homogeneity leads to superior material properties such as increased tensile strength and consistent color dispersion. High-intensity dynamic mixers also reduce mixing times, optimizing production efficiency and enabling better control over temperature-sensitive polymers.

Applications of Static Mixers in the Plastics Industry

Static mixers are widely used in the plastics industry for blending polymer melts, additives, and colorants without moving parts, ensuring consistent product quality and reduced maintenance costs. They enable uniform mixing in extrusion, injection molding, and compounding processes, improving material homogeneity and reducing cycle times. Applications include pigment dispersion, reactive extrusion, and temperature control in thermoplastic and thermoset processing.

Applications of Dynamic Mixers in the Plastics Industry

Dynamic mixers are widely used in the plastics industry for processes requiring thorough melting, blending, and homogenizing of polymers and additives, ensuring consistent material properties. Your production benefits from dynamic mixers' ability to handle high-viscosity materials and facilitate rapid mixing, making them essential for compounding, plastication, and devolatilization applications. These mixers also improve product quality by reducing cycle times and enhancing the uniform dispersion of fillers, pigments, and reinforcements in thermoplastic and thermoset processing.

Factors to Consider When Choosing a Mixing Method

Choosing between static and dynamic mixing in plastics processing depends on factors such as material viscosity, mixing time, and energy efficiency requirements. Static mixers are preferred for low-viscosity materials and continuous flow applications due to their low energy consumption and minimal maintenance. Dynamic mixers are more suitable for high-viscosity materials and complex formulations, offering superior mixing intensity and flexibility in processing variables.

Future Trends in Mixing Technologies for Plastics

Future trends in mixing technologies for plastics emphasize advanced dynamic systems integrated with real-time monitoring and control to optimize material homogeneity and reduce energy consumption. Innovations in static mixers utilize novel geometries and surface treatments to enhance shear efficiency and minimize maintenance requirements. Emerging hybrid mixing solutions combine static and dynamic principles, leveraging automation and AI-driven process adjustments to improve scalability and adapt to the increasing diversity of polymer blends and composites.

Static vs dynamic mixing (plastics processing) Infographic

libmatt.com

libmatt.com