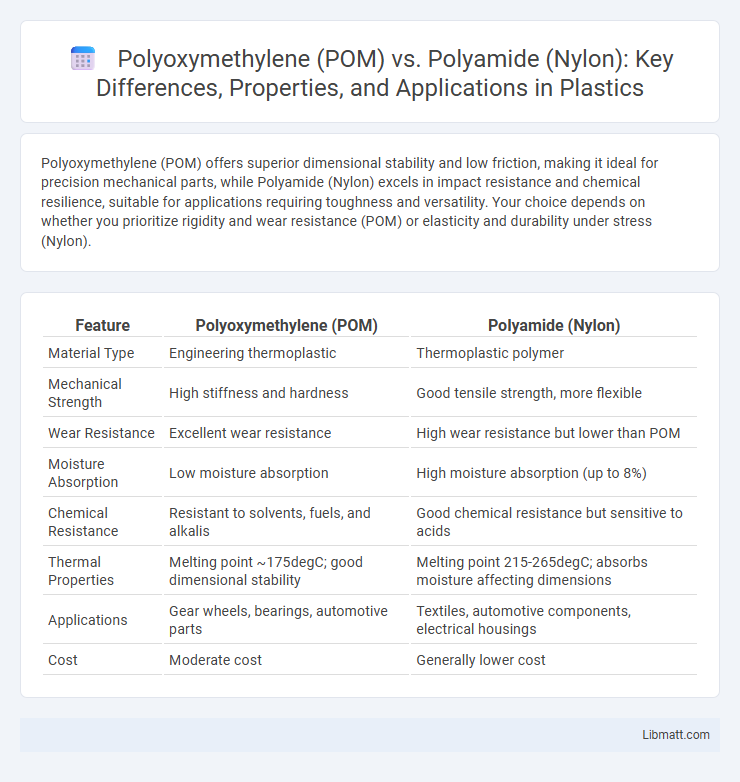

Polyoxymethylene (POM) offers superior dimensional stability and low friction, making it ideal for precision mechanical parts, while Polyamide (Nylon) excels in impact resistance and chemical resilience, suitable for applications requiring toughness and versatility. Your choice depends on whether you prioritize rigidity and wear resistance (POM) or elasticity and durability under stress (Nylon).

Table of Comparison

| Feature | Polyoxymethylene (POM) | Polyamide (Nylon) |

|---|---|---|

| Material Type | Engineering thermoplastic | Thermoplastic polymer |

| Mechanical Strength | High stiffness and hardness | Good tensile strength, more flexible |

| Wear Resistance | Excellent wear resistance | High wear resistance but lower than POM |

| Moisture Absorption | Low moisture absorption | High moisture absorption (up to 8%) |

| Chemical Resistance | Resistant to solvents, fuels, and alkalis | Good chemical resistance but sensitive to acids |

| Thermal Properties | Melting point ~175degC; good dimensional stability | Melting point 215-265degC; absorbs moisture affecting dimensions |

| Applications | Gear wheels, bearings, automotive parts | Textiles, automotive components, electrical housings |

| Cost | Moderate cost | Generally lower cost |

Introduction to Polyoxymethylene (POM) and Polyamide (Nylon)

Polyoxymethylene (POM), also known as acetal, is a high-performance thermoplastic renowned for its excellent dimensional stability, low friction, and high mechanical strength, making it ideal for precision parts and mechanical components. Polyamide (Nylon) offers superior toughness, flexibility, and resistance to abrasion, chemicals, and heat, which is why it is widely used in textiles, automotive parts, and industrial applications. Your selection between POM and Nylon depends on the specific requirements for durability, stiffness, and environmental resistance in your project.

Chemical Structure and Composition Comparison

Polyoxymethylene (POM) is a semi-crystalline thermoplastic polymer characterized by repeating -CH2-O- units, offering high crystallinity and a highly ordered molecular structure that contributes to its rigidity and resistance to solvents. Polyamide (Nylon) consists of repeating amide linkages (-CONH-) formed from the polymerization of diamines and dicarboxylic acids, resulting in a polymer with strong hydrogen bonding that enhances its toughness and moisture absorption properties. The distinct chemical compositions of POM and Nylon directly influence their respective mechanical strengths, thermal stability, and environmental resistance, with POM typically excelling in dimensional stability and Nylon in impact resistance.

Mechanical Properties: Strength, Stiffness, and Toughness

Polyoxymethylene (POM) exhibits higher stiffness and tensile strength compared to Polyamide (Nylon), making it ideal for precision mechanical components requiring dimensional stability. Nylon demonstrates superior toughness and impact resistance due to its higher elongation at break and inherent flexibility, which provides better performance in dynamic or impact-loaded applications. Balancing strength and toughness is essential for your application, with POM favored for rigidity and Nylon preferred for durability under stress.

Thermal Stability and Operating Temperature Range

Polyoxymethylene (POM) exhibits superior thermal stability with a continuous operating temperature range typically between -40degC to 100degC, making it well-suited for applications requiring resistance to heat and dimensional stability. Polyamide (Nylon) generally offers a wider operating temperature range from -40degC up to 120degC but tends to absorb moisture, which can affect its thermal performance and mechanical properties. POM's low moisture absorption and high crystallinity contribute to its enhanced thermal resistance compared to Nylon, especially in environments with fluctuating temperatures.

Wear Resistance and Frictional Behavior

Polyoxymethylene (POM) exhibits superior wear resistance compared to Polyamide (Nylon) due to its high crystallinity and low friction coefficient, making it ideal for precision mechanical parts and sliding applications. Nylon demonstrates higher frictional behavior and moisture absorption, which can reduce dimensional stability and increase wear under humid conditions. Engineering applications requiring low friction and long service life often favor POM for gears, bearings, and bushings where wear resistance is critical.

Moisture Absorption and Dimensional Stability

Polyoxymethylene (POM) exhibits low moisture absorption, typically below 0.2%, which ensures superior dimensional stability and minimal swelling in humid environments. In contrast, Polyamide (Nylon) can absorb moisture up to 8-10%, causing noticeable dimensional changes and reduced mechanical strength. This difference makes POM more suitable for precision components requiring consistent dimensions under varying moisture conditions.

Chemical Resistance and Environmental Impact

Polyoxymethylene (POM) exhibits superior chemical resistance compared to Polyamide (Nylon), showing excellent stability against solvents, fuels, and alkalis, which makes it suitable for harsh chemical environments. In contrast, Nylon is more prone to hydrolysis and degradation when exposed to acids and moisture, reducing its longevity in chemically aggressive or humid conditions. Environmentally, POM offers better recyclability and lower moisture absorption, whereas Nylon's production involves higher energy consumption and emits more greenhouse gases, impacting its overall environmental footprint.

Ease of Processing and Fabrication Methods

Polyoxymethylene (POM) offers excellent ease of processing due to its low melt viscosity, enabling efficient injection molding and precise fabrication of complex parts. Polyamide (Nylon) requires more controlled processing conditions because of its hygroscopic nature and sensitivity to moisture, which can affect dimensional stability during fabrication like extrusion or injection molding. Your choice between POM and Nylon should consider the specific manufacturing environment and desired product tolerance to ensure optimal ease of fabrication.

Typical Applications: POM vs Nylon

Polyoxymethylene (POM) is widely used in precision engineering applications such as gears, bearings, and automotive components due to its high stiffness, low friction, and excellent dimensional stability. Polyamide (Nylon) finds typical applications in textiles, carpets, mechanical parts, and electrical insulation because of its toughness, elasticity, and good chemical resistance. Both materials are essential in manufacturing but are chosen based on specific operational requirements like wear resistance for POM and impact strength for Nylon.

Cost Analysis and Material Selection Guidelines

Polyoxymethylene (POM) typically offers a lower cost per unit weight compared to Polyamide (Nylon), making it a cost-effective choice for high-volume applications requiring precision and low friction. Nylon, while generally higher in price, provides superior toughness, chemical resistance, and thermal stability, which justify its selection in demanding mechanical and automotive components. Material selection should weigh POM's dimensional stability and wear resistance against Nylon's enhanced durability and resistance to moisture and chemicals, aligning with specific application requirements and budget constraints.

Polyoxymethylene (POM) vs Polyamide (Nylon) Infographic

libmatt.com

libmatt.com