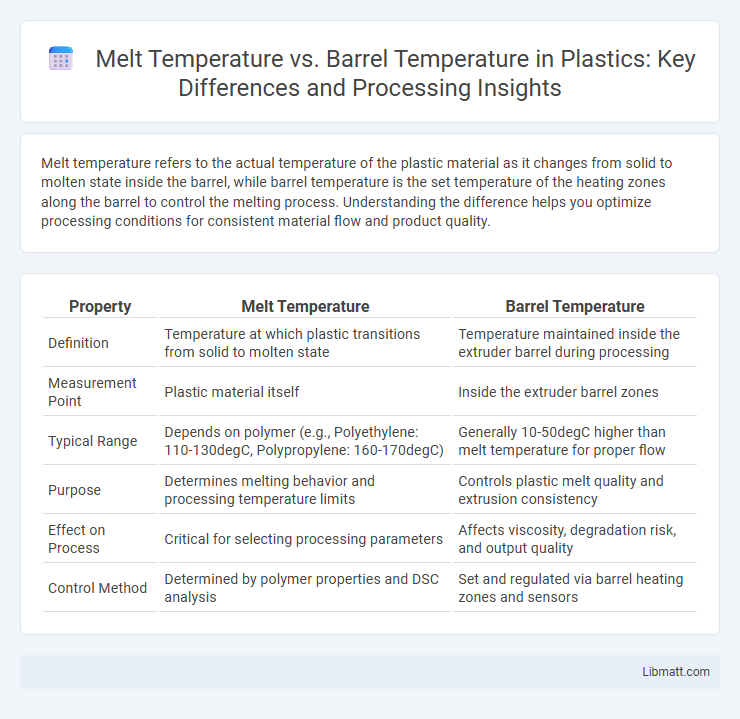

Melt temperature refers to the actual temperature of the plastic material as it changes from solid to molten state inside the barrel, while barrel temperature is the set temperature of the heating zones along the barrel to control the melting process. Understanding the difference helps you optimize processing conditions for consistent material flow and product quality.

Table of Comparison

| Property | Melt Temperature | Barrel Temperature |

|---|---|---|

| Definition | Temperature at which plastic transitions from solid to molten state | Temperature maintained inside the extruder barrel during processing |

| Measurement Point | Plastic material itself | Inside the extruder barrel zones |

| Typical Range | Depends on polymer (e.g., Polyethylene: 110-130degC, Polypropylene: 160-170degC) | Generally 10-50degC higher than melt temperature for proper flow |

| Purpose | Determines melting behavior and processing temperature limits | Controls plastic melt quality and extrusion consistency |

| Effect on Process | Critical for selecting processing parameters | Affects viscosity, degradation risk, and output quality |

| Control Method | Determined by polymer properties and DSC analysis | Set and regulated via barrel heating zones and sensors |

Understanding Melt Temperature and Barrel Temperature

Melt temperature refers to the actual temperature of the polymer melt during processing, which directly impacts material flow and final product quality. Barrel temperature is the setting applied to the extruder or injection molding barrel, influencing the heat transfer to the polymer and affecting the consistency of the melt temperature. Precise control and monitoring of both temperatures are critical for optimizing polymer processing, reducing defects, and ensuring dimensional stability in plastic manufacturing.

Key Differences Between Melt Temperature and Barrel Temperature

Melt temperature measures the actual temperature of the polymer melt inside the barrel, directly affecting material flow behavior and final product quality. Barrel temperature refers to the set temperature of the heater bands surrounding the barrel, controlling heat input but not indicating the real melt conditions. Precise control of melt temperature ensures optimal viscosity and avoids degradation, while barrel temperature provides a general thermal environment for consistent processing.

Why Melt Temperature Matters in Polymer Processing

Melt temperature directly affects the polymer's flow behavior, impacting extrusion and injection molding quality by ensuring uniform viscosity and minimizing defects like bubbles or weak weld lines. Maintaining the optimal melt temperature prevents thermal degradation, which preserves the polymer's mechanical properties and enhances final product performance. Controlling melt temperature precisely improves dimensional accuracy and surface finish, critical factors in high-precision polymer applications.

The Role of Barrel Temperature in Injection Molding

Barrel temperature in injection molding critically influences the melt temperature by controlling the polymer's viscosity and flow characteristics within the barrel. Proper barrel temperature ensures consistent melt consistency, reducing defects like incomplete filling or burn marks while optimizing cycle times. Maintaining precise barrel temperature profiles enhances product quality and dimensional stability in thermoplastic molding processes.

Factors Affecting Melt Temperature Control

Melt temperature control depends heavily on the polymer type, screw design, and shear rate within the barrel. Precise barrel temperature settings are crucial as they directly influence the melt viscosity and homogeneity, impacting product quality. External factors like ambient temperature, cooling system efficiency, and machine wear also affect the consistency of melt temperature during processing.

How Barrel Temperature Influences Melt Quality

Barrel temperature directly affects melt quality by controlling the viscosity and homogeneity of the molten material during processing. Maintaining an optimal barrel temperature ensures consistent melting and reduces the risk of thermal degradation, leading to higher product uniformity and mechanical properties. Your precise control of barrel temperature can optimize melt flow behavior, improving the overall efficiency of extrusion or injection molding processes.

Measuring Melt Temperature: Best Practices

Measuring melt temperature accurately requires placing the sensor directly in the melt stream, avoiding contact with the barrel wall to prevent skewed readings caused by heat conduction. Use specialized melt temperature sensors or infrared probes designed for high-temperature plastic melts to ensure precise data collection. Consistent monitoring of melt temperature supports optimal processing, helping you maintain product quality and reduce material degradation.

Common Mistakes in Setting Barrel Temperature

Setting barrel temperature incorrectly can lead to inconsistent melt temperature, causing poor material flow and defects in your final product. A common mistake is relying solely on barrel temperature settings without monitoring actual melt temperature, resulting in overheating or incomplete melting. Ensuring proper calibration and using melt temperature sensors improves process control and product quality.

Melt Temperature vs Barrel Temperature: Impact on Product Quality

Melt temperature directly affects polymer viscosity and flow behavior, crucial for achieving uniform material consistency during injection molding. Barrel temperature settings influence the heat transfer rate to the polymer, impacting melt homogeneity and reducing defects like voids, weld lines, or incomplete filling. Precise control and optimization of melt versus barrel temperature ensure improved surface finish, dimensional accuracy, and enhanced mechanical properties of the final product.

Optimizing Processing Parameters for Consistent Results

Melt temperature directly affects polymer viscosity and flow, while barrel temperature controls the overall thermal environment in extrusion or injection molding. Precise calibration between melt temperature and barrel temperature ensures consistent melt quality, minimizes degradation, and enhances product uniformity. Optimizing these parameters helps you achieve reliable processing conditions for high-quality, repeatable output.

Melt temperature vs barrel temperature Infographic

libmatt.com

libmatt.com