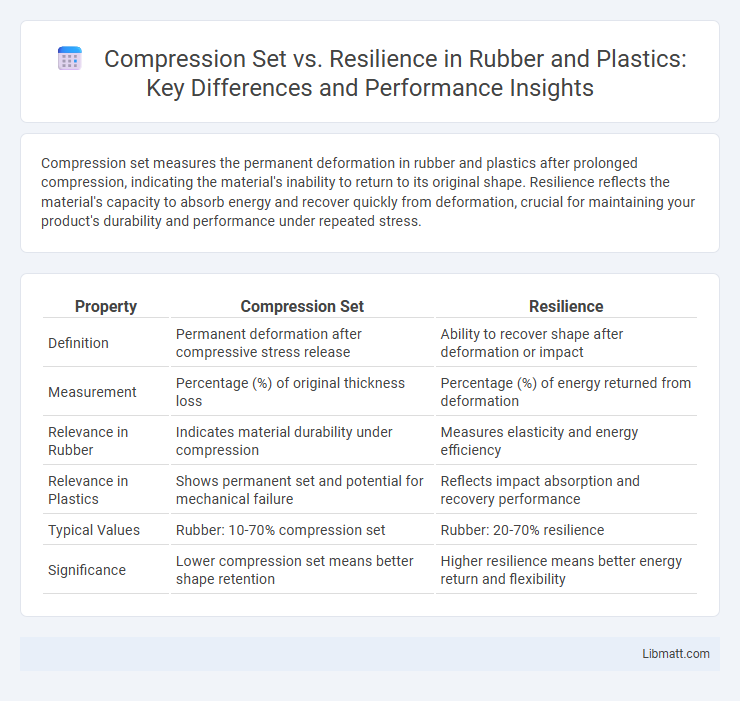

Compression set measures the permanent deformation in rubber and plastics after prolonged compression, indicating the material's inability to return to its original shape. Resilience reflects the material's capacity to absorb energy and recover quickly from deformation, crucial for maintaining your product's durability and performance under repeated stress.

Table of Comparison

| Property | Compression Set | Resilience |

|---|---|---|

| Definition | Permanent deformation after compressive stress release | Ability to recover shape after deformation or impact |

| Measurement | Percentage (%) of original thickness loss | Percentage (%) of energy returned from deformation |

| Relevance in Rubber | Indicates material durability under compression | Measures elasticity and energy efficiency |

| Relevance in Plastics | Shows permanent set and potential for mechanical failure | Reflects impact absorption and recovery performance |

| Typical Values | Rubber: 10-70% compression set | Rubber: 20-70% resilience |

| Significance | Lower compression set means better shape retention | Higher resilience means better energy return and flexibility |

Introduction to Compression Set and Resilience

Compression set measures the permanent deformation of rubber or plastic after prolonged compressive stress, indicating material's ability to return to its original thickness. Resilience quantifies the material's capacity to absorb and recover energy during deformation, reflecting elasticity and impact resistance. Understanding these properties helps you evaluate performance and durability in applications requiring flexible sealing or cushioning.

Defining Compression Set in Rubber and Plastics

Compression set in rubber and plastics measures the material's ability to return to its original thickness after prolonged compressive stress, indicating permanent deformation. It quantifies the loss of elasticity by evaluating how much a material fails to recover, which directly impacts sealing effectiveness and durability. Understanding compression set helps you select materials that maintain performance under continuous load conditions.

Understanding Resilience in Elastomers

Resilience in elastomers measures their ability to recover energy after deformation, reflecting the material's elasticity and efficiency under cyclic stress. Compression set, on the other hand, quantifies permanent deformation after prolonged compression, indicating the extent of material relaxation or failure to return to original thickness. Understanding resilience helps you select elastomers that maintain performance and durability in dynamic applications where energy return and shape recovery are critical.

Key Differences Between Compression Set and Resilience

Compression set measures the permanent deformation of rubber and plastics after prolonged compressive stress, indicating material's inability to return to its original thickness. Resilience quantifies the ability of these materials to absorb energy during deformation and recover quickly without permanent distortion. Understanding these key differences helps you select materials based on whether long-term shape retention or rapid energy recovery is crucial for your application.

Factors Affecting Compression Set Performance

Compression set performance in rubber and plastics is influenced by material composition, temperature, duration of applied stress, and environmental exposure such as ozone or chemicals. The crosslink density and polymer structure significantly affect the ability to recover from deformation, while additives and fillers can enhance or diminish the material's resilience. Understanding these factors helps optimize Your selection for applications requiring durable sealing or cushioning properties.

Variables Influencing Resilience Characteristics

Resilience in rubber and plastics is primarily influenced by variables such as material composition, temperature, and strain rate, which determine the ability of the material to recover its shape after deformation. Compression set, reflecting permanent deformation after prolonged stress, inversely correlates with resilience, and factors like crosslink density, filler content, and aging impact both properties significantly. Understanding the interplay between these variables supports the optimization of elastomeric components for performance under mechanical stress.

Material Selection: Rubber vs. Plastics

Rubber materials typically exhibit higher resilience and lower compression set compared to plastics, making them preferable for dynamic sealing applications where material recovery and durability under repeated stress are crucial. Plastics, while generally having higher compression set indicating greater permanent deformation, offer advantages in chemical resistance and structural rigidity, which suit static load environments. Understanding the balance between compression set and resilience is essential for selecting the optimal material based on application-specific mechanical and environmental requirements.

Real-World Applications and Implications

Compression set measures a material's permanent deformation after prolonged compression, critical for ensuring seals and gaskets maintain their shape and function in automotive and industrial applications. Resilience evaluates the material's ability to recover energy after deformation, essential for shock absorption in footwear soles and vibration damping in electronic devices. Your choice between these properties directly impacts product durability, performance, and safety in real-world rubber and plastic components.

Testing Methods for Compression Set and Resilience

Testing methods for Compression Set in rubber and plastics typically involve measuring the material's deformation after prolonged compressive stress at a specified temperature and duration, with standards such as ASTM D395 guiding the procedure. Resilience testing evaluates the material's ability to return energy after impact or deformation, often using ASTM D2632 for rubber or similar methods assessing rebound height or energy absorption. Your selection of testing methods should align with the material's application requirements to ensure accurate assessment of long-term performance and elasticity.

Optimizing Material Properties for Industrial Use

Compression set measures the permanent deformation of rubber and plastics after prolonged compression, directly affecting the sealing efficiency and longevity of industrial components. Resilience indicates the material's ability to recover its shape after deformation, crucial for applications requiring repeated flexing or impact resistance. Optimizing Your industrial materials requires balancing low compression set for durability and high resilience for energy absorption to enhance performance and extend service life.

Compression Set vs Resilience in Rubber and Plastics Infographic

libmatt.com

libmatt.com