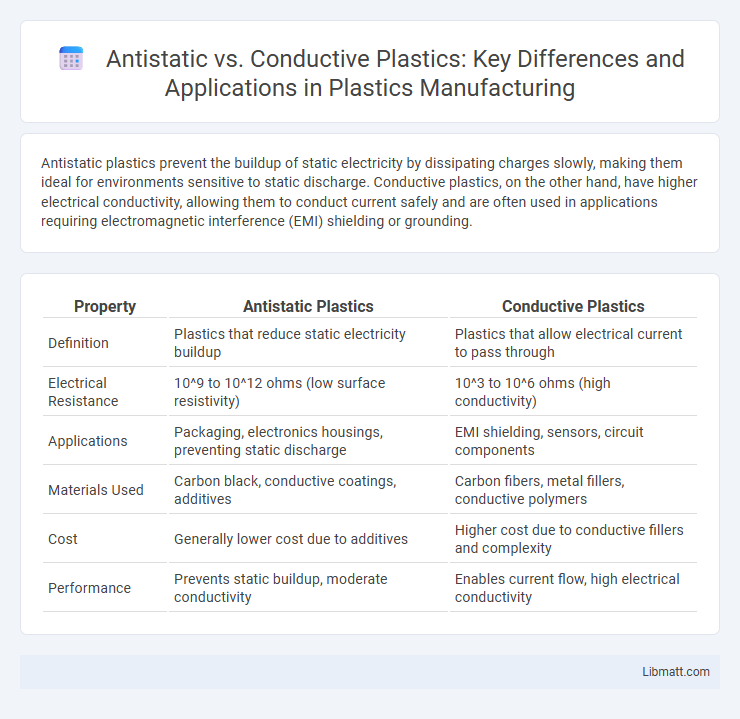

Antistatic plastics prevent the buildup of static electricity by dissipating charges slowly, making them ideal for environments sensitive to static discharge. Conductive plastics, on the other hand, have higher electrical conductivity, allowing them to conduct current safely and are often used in applications requiring electromagnetic interference (EMI) shielding or grounding.

Table of Comparison

| Property | Antistatic Plastics | Conductive Plastics |

|---|---|---|

| Definition | Plastics that reduce static electricity buildup | Plastics that allow electrical current to pass through |

| Electrical Resistance | 10^9 to 10^12 ohms (low surface resistivity) | 10^3 to 10^6 ohms (high conductivity) |

| Applications | Packaging, electronics housings, preventing static discharge | EMI shielding, sensors, circuit components |

| Materials Used | Carbon black, conductive coatings, additives | Carbon fibers, metal fillers, conductive polymers |

| Cost | Generally lower cost due to additives | Higher cost due to conductive fillers and complexity |

| Performance | Prevents static buildup, moderate conductivity | Enables current flow, high electrical conductivity |

Understanding Antistatic and Conductive Plastics

Antistatic plastics reduce surface static electricity buildup, preventing dust attraction and minor shocks, while conductive plastics allow electrical current to flow through them, offering effective dissipation of static charges. Your choice depends on the application's need for static control, where antistatic materials suit environments with low charge generation, and conductive plastics are essential for safely grounding high-charge areas. Understanding the electrical properties and use cases ensures optimal protection against static-related damage or hazards.

Key Differences Between Antistatic and Conductive Plastics

Antistatic plastics prevent the buildup of static electricity by dissipating charges slowly, whereas conductive plastics allow the flow of electrical current due to their low resistivity. The surface resistivity of antistatic plastics typically ranges from 10^9 to 10^12 ohms/square, while conductive plastics exhibit much lower resistivity, often below 10^5 ohms/square. Choosing between antistatic and conductive plastics depends on whether you need to control static discharge or enable electrical conduction in your application.

How Antistatic Plastics Work

Antistatic plastics reduce static electricity buildup by incorporating additives that increase surface conductivity, allowing static charges to dissipate quickly. These materials prevent dust attraction and electrical discharge by maintaining a surface resistivity typically between 10^9 to 10^12 ohms. Unlike conductive plastics, which have higher conductivity due to carbon black or metal fillers, antistatic plastics balance electrical performance with maintaining original plastic properties.

How Conductive Plastics Function

Conductive plastics function by incorporating conductive fillers such as carbon black, metal fibers, or conductive polymers into the polymer matrix, enabling the material to conduct electricity. The conductive pathways formed by these fillers allow for the dissipation of static charges and electromagnetic interference, making them suitable for applications requiring reliable electrical grounding. Their electrical conductivity is typically measured in ohms per square, with values tailored to meet specific industry standards for electrostatic discharge (ESD) protection.

Common Applications of Antistatic Plastics

Antistatic plastics are widely used in electronic device housings, packaging for sensitive electronic components, and cleanroom environments to prevent static charge buildup that can damage circuitry. These materials are preferred in manufacturing medical equipment, automotive parts, and aerospace components where static dissipation is critical for safety and performance. Their ability to avoid electrostatic discharge makes them essential in the production of semiconductor trays, control panels, and precision instruments.

Typical Uses of Conductive Plastics

Conductive plastics are commonly used in electronic enclosures, electromagnetic interference (EMI) shielding, and static dissipative flooring. These materials effectively prevent electrostatic discharge (ESD) in sensitive electronic components, ensuring device protection and reliability. Your choice of conductive plastic can enhance performance in industries such as aerospace, automotive, and telecommunications where controlling electrical conductivity is critical.

Material Properties: Antistatic vs Conductive Plastics

Antistatic plastics possess surface resistivity typically between 10^9 to 10^12 ohms/square, allowing them to dissipate static electricity without conducting current, making them ideal for preventing static buildup in sensitive environments. Conductive plastics exhibit much lower resistivity, often below 10^5 ohms/square, incorporating conductive fillers like carbon black or metal particles to enable electrical conductivity for electromagnetic interference (EMI) shielding or grounding applications. The differing material properties determine their suitability: antistatic plastics reduce static charge accumulation, while conductive plastics provide effective pathways for electrical current flow.

Choosing the Right Plastic for ESD Protection

Choosing the right plastic for ESD protection hinges on understanding the differences between antistatic and conductive plastics. Antistatic plastics reduce surface charge buildup by dissipating static electricity slowly, suitable for environments with low static discharge risk. Conductive plastics provide a low-resistance path for static charge dissipation, offering superior protection in high-risk ESD applications where rapid discharge is essential to safeguard your sensitive electronic components.

Testing and Standards for Antistatic and Conductive Plastics

Testing of antistatic and conductive plastics involves measuring surface resistivity and volume resistivity according to standards such as ASTM D257 and IEC 60093, ensuring materials meet required performance criteria. These plastics are evaluated using standardized methods like the AATCC 134 for static decay and ISO 284 for electrical properties to guarantee effective electrostatic discharge protection. Compliance with industry-specific standards, including MIL-STD-3010 for military applications and ANSI/ESD S20.20 for electronics manufacturing, is critical to validate the antistatic and conductive functionality of plastic materials.

Future Trends in Antistatic and Conductive Plastic Technology

Future trends in antistatic and conductive plastic technology emphasize the integration of nanomaterials like graphene and carbon nanotubes to significantly enhance electrical conductivity while maintaining lightweight properties. Advances in biodegradable and eco-friendly polymers aim to reduce environmental impact without compromising performance. You can expect improvements in customization for specific industries such as electronics, automotive, and aerospace, driven by the demand for smarter, safer, and more sustainable materials.

Antistatic vs Conductive Plastics Infographic

libmatt.com

libmatt.com