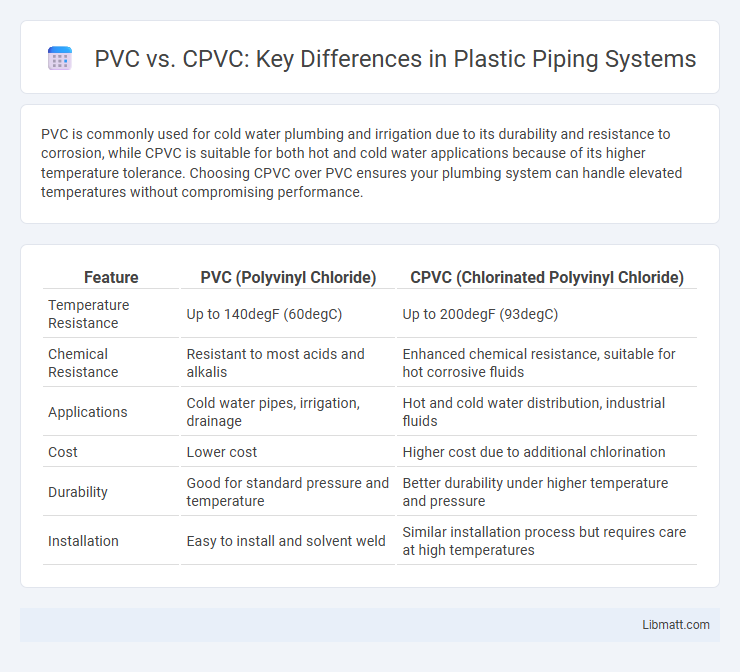

PVC is commonly used for cold water plumbing and irrigation due to its durability and resistance to corrosion, while CPVC is suitable for both hot and cold water applications because of its higher temperature tolerance. Choosing CPVC over PVC ensures your plumbing system can handle elevated temperatures without compromising performance.

Table of Comparison

| Feature | PVC (Polyvinyl Chloride) | CPVC (Chlorinated Polyvinyl Chloride) |

|---|---|---|

| Temperature Resistance | Up to 140degF (60degC) | Up to 200degF (93degC) |

| Chemical Resistance | Resistant to most acids and alkalis | Enhanced chemical resistance, suitable for hot corrosive fluids |

| Applications | Cold water pipes, irrigation, drainage | Hot and cold water distribution, industrial fluids |

| Cost | Lower cost | Higher cost due to additional chlorination |

| Durability | Good for standard pressure and temperature | Better durability under higher temperature and pressure |

| Installation | Easy to install and solvent weld | Similar installation process but requires care at high temperatures |

Introduction to PVC and CPVC

PVC (Polyvinyl Chloride) is a widely used plastic material known for its durability, chemical resistance, and affordability, commonly utilized in plumbing and construction. CPVC (Chlorinated Polyvinyl Chloride) is a modified version of PVC that can withstand higher temperatures and pressure, making it ideal for hot water systems and industrial applications. Your choice between PVC and CPVC depends on the specific temperature and pressure requirements of your project.

Chemical Composition Differences

PVC (Polyvinyl Chloride) consists primarily of vinyl chloride monomers, characterized by its rigid structure and resistance to chemicals like acids and alkalis. CPVC (Chlorinated Polyvinyl Chloride) is produced by chlorinating PVC, increasing the chlorine content, which enhances its thermal stability and chemical resistance, especially against corrosive substances. The higher chlorine percentage in CPVC allows it to withstand higher temperatures and more aggressive chemicals compared to standard PVC.

Physical Properties Comparison

PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) differ significantly in physical properties, impacting their applications. CPVC has a higher temperature tolerance, often rated up to 200degF (93degC), compared to PVC's maximum of around 140degF (60degC), making CPVC suitable for hot water systems. You should consider CPVC's enhanced chemical resistance and greater flexibility, while PVC offers superior stiffness and lower cost for cold water and drainage systems.

Temperature Resistance

PVC (Polyvinyl Chloride) pipes have a temperature resistance limit of up to 140degF (60degC), making them suitable for cold water applications and drainage systems. CPVC (Chlorinated Polyvinyl Chloride) pipes can withstand higher temperatures up to 200degF (93degC), which allows their use in hot water distribution and industrial liquids. The increased chlorine content in CPVC enhances its thermal stability and durability compared to PVC.

Pressure Ratings

PVC and CPVC pipes differ significantly in pressure ratings, with CPVC typically able to withstand pressures up to 1000 psi at 73degF, making it suitable for hot water applications, while PVC usually handles pressures up to 450 psi at the same temperature primarily for cold water. The higher pressure tolerance of CPVC is due to its chlorinated molecular structure, enhancing strength and thermal resistance. This distinction is critical for engineers and plumbers selecting materials for systems requiring reliable performance under varying temperature and pressure conditions.

Cost Effectiveness

PVC pipes generally offer greater cost effectiveness than CPVC due to their lower material price and widespread availability, making them ideal for budget-conscious plumbing projects. While CPVC pipes cost more upfront, their superior chemical resistance and higher temperature tolerance can reduce maintenance and replacement expenses over time. Choosing between PVC and CPVC depends on balancing initial investment against long-term durability and performance requirements.

Common Applications

PVC excels in cold water plumbing, irrigation systems, and drainage due to its durability and affordability, while CPVC is preferred for hot water applications because of its higher temperature resistance. Your choice for residential or commercial piping often depends on the temperature requirements of the system, with CPVC used in heating and fire sprinkler systems. Both materials are common in water supply networks, but CPVC offers enhanced chemical and heat resistance, making it suitable for industrial applications as well.

Installation and Handling

PVC pipes offer easier installation due to their lighter weight and flexibility, requiring solvent cement joining methods that set quickly. CPVC, although slightly heavier and more rigid, withstands higher temperatures and uses similar solvent welding techniques but demands more precise handling to avoid cracking during installation. Both materials benefit from standard cutting and joining tools, but CPVC's higher temperature ratings make it suitable for hot water systems where durability under heat stress is critical.

Durability and Longevity

CPVC (Chlorinated Polyvinyl Chloride) offers superior durability and longevity compared to standard PVC due to its enhanced resistance to heat, chemical corrosion, and impact. CPVC can withstand temperatures up to 200degF, making it ideal for hot water applications, whereas PVC typically handles temperatures only up to 140degF. The increased thermal stability of CPVC ensures a longer service life in demanding environments, reducing the need for frequent replacements.

Safety and Environmental Considerations

CPVC offers enhanced safety over PVC due to its ability to withstand higher temperatures, reducing the risk of deformation and chemical leaching in hot water applications. Both PVC and CPVC are generally considered safe for potable water systems, but CPVC's chlorine resistance contributes to longer lifespan and lower maintenance, minimizing environmental impact. PVC production involves chlorinated compounds that may release harmful emissions if improperly disposed of, whereas CPVC's improved durability supports sustainability through reduced replacement frequency.

PVC vs CPVC Infographic

libmatt.com

libmatt.com