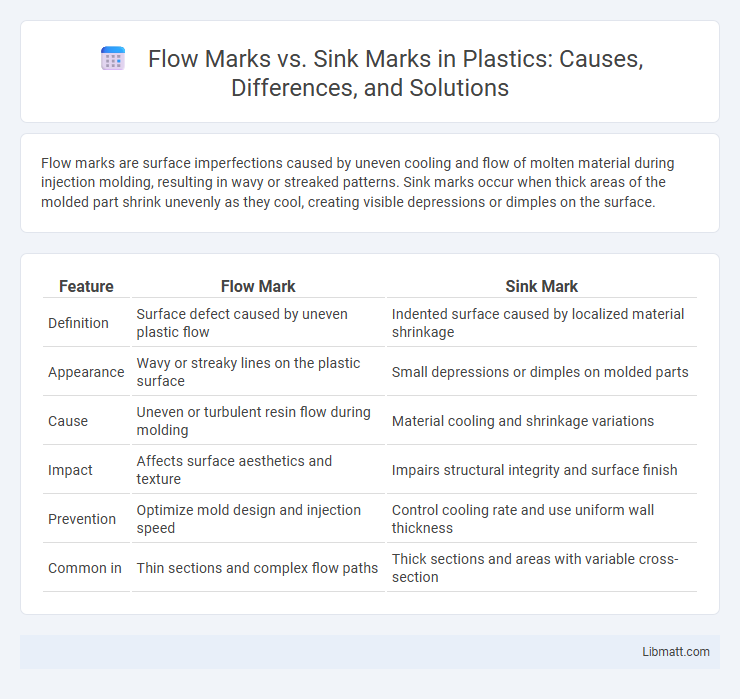

Flow marks are surface imperfections caused by uneven cooling and flow of molten material during injection molding, resulting in wavy or streaked patterns. Sink marks occur when thick areas of the molded part shrink unevenly as they cool, creating visible depressions or dimples on the surface.

Table of Comparison

| Feature | Flow Mark | Sink Mark |

|---|---|---|

| Definition | Surface defect caused by uneven plastic flow | Indented surface caused by localized material shrinkage |

| Appearance | Wavy or streaky lines on the plastic surface | Small depressions or dimples on molded parts |

| Cause | Uneven or turbulent resin flow during molding | Material cooling and shrinkage variations |

| Impact | Affects surface aesthetics and texture | Impairs structural integrity and surface finish |

| Prevention | Optimize mold design and injection speed | Control cooling rate and use uniform wall thickness |

| Common in | Thin sections and complex flow paths | Thick sections and areas with variable cross-section |

Introduction to Flow Marks and Sink Marks

Flow marks and sink marks are common surface defects in injection molding that affect the quality and appearance of plastic parts. Flow marks appear as wavy or streaky patterns caused by uneven cooling or inconsistent mold filling, while sink marks are small surface depressions resulting from localized shrinkage as the material cools and contracts. Understanding these defects helps you optimize mold design, material selection, and processing conditions to enhance the final product's structural integrity and visual appeal.

Understanding Flow Marks: Causes and Characteristics

Flow marks are surface defects in injection molding caused by variations in resin flow, often due to abrupt changes in mold geometry or inadequate gate design, which disrupt the polymer melt's smooth progression. These marks appear as wavy or streaky lines on the molded part, typically near the gate or along flow paths where the material cools unevenly. Understanding these characteristics aids in optimizing mold design and processing parameters to minimize defects and enhance product quality.

Defining Sink Marks: Origins and Appearance

Sink marks form as depressions on molded plastic surfaces caused by localized shrinkage during cooling, typically occurring where thicker sections cool slower than surrounding areas. These defects often appear as circular or oval indentations, impacting surface aesthetics and structural integrity in injection-molded parts. Understanding their formation helps manufacturers optimize mold design and processing conditions to minimize sink mark occurrence.

Key Differences Between Flow Marks and Sink Marks

Flow marks and sink marks differ primarily in their formation and appearance; flow marks appear as wavy or streaky lines on the surface caused by uneven cooling or improper flow of molten material, while sink marks are dimples or depressions caused by material shrinkage as it cools and contracts. Flow marks typically indicate issues with injection speed or temperature, affecting surface quality, whereas sink marks signal inadequate packing pressure or cooling time, impacting part thickness and structural integrity. Understanding these differences helps you optimize molding parameters to improve product quality and reduce defects effectively.

Common Materials Prone to Flow and Sink Marks

Common materials prone to flow marks include polypropylene (PP), polyethylene (PE), and polystyrene (PS) due to their flow characteristics and cooling behavior. Sink marks frequently appear in parts made from acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and nylon, where thicker sections cool unevenly, causing surface depressions. Understanding the thermal and flow properties of these thermoplastics is crucial for optimizing mold design and processing parameters to minimize defects.

Impact of Molding Parameters on Defect Formation

Flow marks and sink marks significantly affect the quality of injection molded parts, with molding parameters directly influencing their formation. High melt temperatures and low injection speeds often cause flow marks due to improper polymer flow, while insufficient packing pressure and inappropriate cooling times lead to sink marks by causing localized material shrinkage. Optimizing parameters such as injection speed, packing pressure, melt temperature, and cooling duration helps minimize these defects, ensuring consistent surface finish and dimensional stability.

Detection and Inspection Methods for Surface Defects

Flow marks and sink marks are detected through visual inspection and non-destructive testing techniques like dye penetrant and ultrasonic testing. Flow marks appear as wavy or streaky lines on the surface, typically identified during visual inspection, while sink marks are depressions or dimples that often require tactile measurement or 3D scanning for precise detection. Your inspection process can be optimized by combining high-resolution cameras for surface imaging with advanced sensors to distinguish between these common injection molding defects.

Preventive Measures for Flow Marks

Preventive measures for flow marks include optimizing mold temperature, ensuring proper venting, and adjusting injection speed to promote uniform filling and prevent resin cooling inconsistencies. Using higher melt temperatures and modifying gate design can also reduce flow mark formation by enhancing melt flow and reducing flow hesitation. Proper mold maintenance and applying surface coatings further contribute to a smoother finish and minimize flow mark defects.

Strategies to Minimize Sink Marks

To minimize sink marks in molded parts, optimize gate location and maintain uniform wall thickness to ensure even material flow and cooling. Implementing proper cooling system design and adjusting packing pressure can significantly reduce sink mark formation by controlling shrinkage during solidification. Your injection molding process benefits from using flow analysis software to predict potential sink mark areas and refine process parameters effectively.

Conclusion: Optimizing Plastic Parts for Defect-Free Surfaces

Flow marks and sink marks are common defects affecting the surface quality of plastic parts, with flow marks appearing as wavy patterns caused by inconsistent cooling and flow, while sink marks arise from material shrinkage during solidification. Optimizing processing parameters such as injection speed, mold temperature, and cooling time can significantly reduce these defects, leading to improved surface finish and structural integrity. Employing advanced simulation tools and selecting compatible materials further enhance defect mitigation, ensuring high-quality, aesthetically pleasing plastic components.

Flow Mark vs Sink Mark Infographic

libmatt.com

libmatt.com