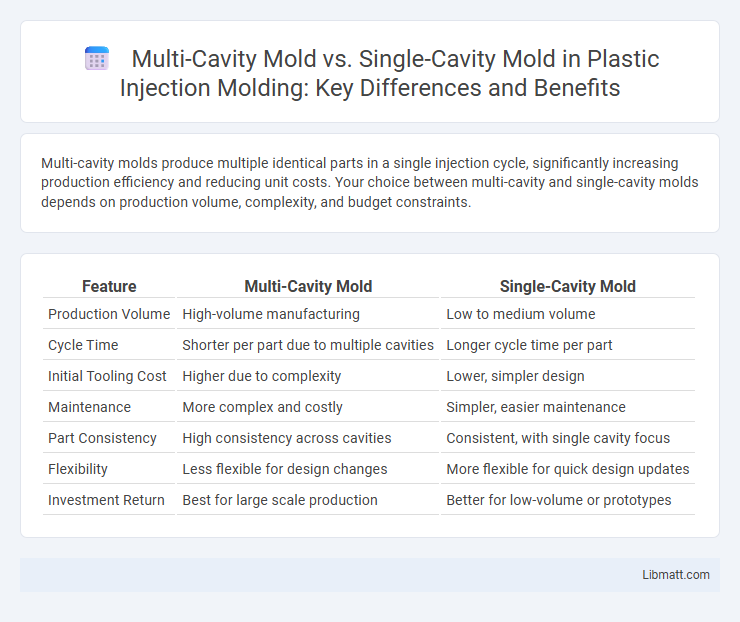

Multi-cavity molds produce multiple identical parts in a single injection cycle, significantly increasing production efficiency and reducing unit costs. Your choice between multi-cavity and single-cavity molds depends on production volume, complexity, and budget constraints.

Table of Comparison

| Feature | Multi-Cavity Mold | Single-Cavity Mold |

|---|---|---|

| Production Volume | High-volume manufacturing | Low to medium volume |

| Cycle Time | Shorter per part due to multiple cavities | Longer cycle time per part |

| Initial Tooling Cost | Higher due to complexity | Lower, simpler design |

| Maintenance | More complex and costly | Simpler, easier maintenance |

| Part Consistency | High consistency across cavities | Consistent, with single cavity focus |

| Flexibility | Less flexible for design changes | More flexible for quick design updates |

| Investment Return | Best for large scale production | Better for low-volume or prototypes |

Introduction to Injection Molding

Injection molding is a manufacturing process used to produce plastic parts by injecting molten material into a mold cavity. Multi-cavity molds contain multiple identical cavities, allowing for the production of several parts in one cycle, increasing efficiency and output. Single-cavity molds produce one part per cycle, offering greater flexibility and lower initial costs, which can be ideal depending on your production volume and design complexity.

What is a Single-Cavity Mold?

A single-cavity mold produces one part per molding cycle, making it ideal for low to medium production volumes or prototypes. It features a single cavity formed within the mold where molten material is injected, cooled, and solidified to create one finished component. Single-cavity molds offer advantages in lower upfront costs and simpler design compared to multi-cavity molds.

What is a Multi-Cavity Mold?

A multi-cavity mold is a type of injection mold designed with multiple cavities to produce several identical parts in a single molding cycle, significantly increasing production efficiency. Each cavity replicates the same part design, allowing manufacturers to meet high-volume demands while maintaining consistent quality across all molded pieces. Your production output can be boosted substantially by utilizing multi-cavity molds without compromising precision or material usage.

Key Differences Between Multi-Cavity and Single-Cavity Molds

Multi-cavity molds produce multiple identical parts in one cycle, increasing production efficiency and reducing unit cost, whereas single-cavity molds produce one part per cycle, offering greater precision and easier mold maintenance. Multi-cavity molds require more complex tooling and balanced runner systems to ensure uniform filling and part quality. Single-cavity molds are typically preferred for low-volume production or prototypes due to their simpler design and faster cycle adjustments.

Production Efficiency and Cycle Time

Multi-cavity molds significantly enhance production efficiency by producing multiple parts per cycle, reducing cycle time compared to single-cavity molds that produce one part at a time. The shorter cycle time in multi-cavity molds allows for higher output rates, ideal for large-scale manufacturing. Single-cavity molds offer longer cycle times but provide greater flexibility for prototyping and low-volume production runs.

Cost Comparison: Initial Investment vs. Long-Term Savings

Multi-cavity molds require a higher initial investment due to their complex design and manufacturing costs but offer significant long-term savings by producing multiple parts per cycle, increasing production efficiency. Single-cavity molds have lower upfront costs, making them suitable for low-volume productions or prototyping, but result in higher per-part costs and longer cycle times compared to multi-cavity options. Choosing between the two depends on balancing upfront expenditure with projected production volume and cost-per-part requirements.

Part Quality and Consistency

Multi-cavity molds provide higher part consistency by producing identical components simultaneously, reducing variation caused by machine or material fluctuations. Single-cavity molds often yield superior part quality with less potential for defects since each cavity undergoes individualized process control. Your production goals should guide the choice, balancing the need for consistent mass production against the highest quality per part.

Applications and Ideal Use Cases

Multi-cavity molds are ideal for high-volume production in industries such as automotive, consumer electronics, and packaging, where consistent and rapid manufacturing of identical parts is critical. Single-cavity molds suit low-volume or custom manufacturing scenarios, including prototyping and specialized medical devices, where precision and flexibility take precedence over output speed. The choice between the two depends on production scale, budget constraints, and the complexity of part design requirements.

Factors to Consider When Choosing Mold Type

When choosing between multi-cavity mold and single-cavity mold, consider factors such as production volume, cost efficiency, and part consistency. Multi-cavity molds are ideal for high-volume manufacturing as they allow multiple parts to be produced simultaneously, reducing cycle time and per-unit cost. Your decision should also weigh mold complexity, maintenance requirements, and ensuring that the chosen mold supports the desired part quality and manufacturing lead times.

Conclusion: Selecting the Right Mold for Your Project

Choosing between a multi-cavity mold and a single-cavity mold depends on your production volume, budget, and project timeline. Multi-cavity molds increase output and reduce cost per part, making them ideal for high-volume manufacturing, while single-cavity molds offer lower upfront costs and flexibility for smaller runs or prototyping. Your decision should balance efficiency with project specifics to optimize manufacturing performance.

Multi-Cavity Mold vs Single-Cavity Mold Infographic

libmatt.com

libmatt.com