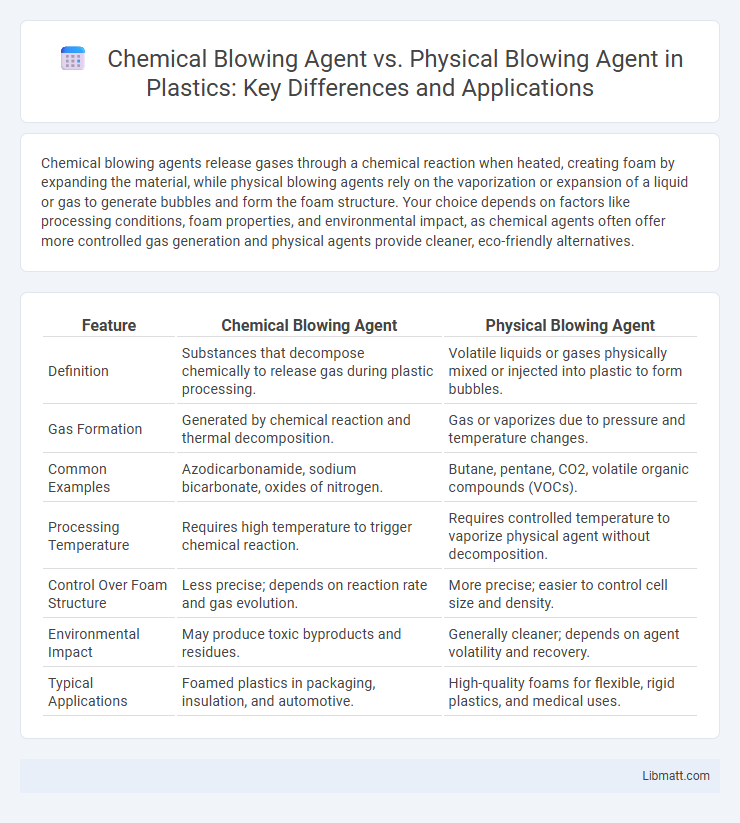

Chemical blowing agents release gases through a chemical reaction when heated, creating foam by expanding the material, while physical blowing agents rely on the vaporization or expansion of a liquid or gas to generate bubbles and form the foam structure. Your choice depends on factors like processing conditions, foam properties, and environmental impact, as chemical agents often offer more controlled gas generation and physical agents provide cleaner, eco-friendly alternatives.

Table of Comparison

| Feature | Chemical Blowing Agent | Physical Blowing Agent |

|---|---|---|

| Definition | Substances that decompose chemically to release gas during plastic processing. | Volatile liquids or gases physically mixed or injected into plastic to form bubbles. |

| Gas Formation | Generated by chemical reaction and thermal decomposition. | Gas or vaporizes due to pressure and temperature changes. |

| Common Examples | Azodicarbonamide, sodium bicarbonate, oxides of nitrogen. | Butane, pentane, CO2, volatile organic compounds (VOCs). |

| Processing Temperature | Requires high temperature to trigger chemical reaction. | Requires controlled temperature to vaporize physical agent without decomposition. |

| Control Over Foam Structure | Less precise; depends on reaction rate and gas evolution. | More precise; easier to control cell size and density. |

| Environmental Impact | May produce toxic byproducts and residues. | Generally cleaner; depends on agent volatility and recovery. |

| Typical Applications | Foamed plastics in packaging, insulation, and automotive. | High-quality foams for flexible, rigid plastics, and medical uses. |

Introduction to Blowing Agents

Blowing agents are substances used to create cellular structures in polymers, enhancing insulation and reducing weight. Chemical blowing agents decompose under heat to release gases such as nitrogen or carbon dioxide, forming bubbles within the material. Physical blowing agents rely on phase change, typically vaporizing a liquid under heat or pressure to generate gas and form foam.

Defining Chemical Blowing Agents

Chemical blowing agents are substances that decompose chemically when heated, releasing gases such as nitrogen, carbon dioxide, or water vapor to create cellular structures in polymers and foams. These agents enable precise control over pore size and density by adjusting reaction conditions and agent concentration. Compared to physical blowing agents, chemical blowing agents offer improved thermal stability and uniformity in foam production.

Defining Physical Blowing Agents

Physical blowing agents are volatile liquids or gases that create cellular foam structures by vaporizing under heat, causing expansion without undergoing chemical reactions. Common physical blowing agents include hydrocarbons like pentane, hydrofluorocarbons (HFCs), and carbon dioxide, which evaporate during polymer processing to form foam. Their key advantage lies in producing consistent foam density and fine cell structures while maintaining material integrity.

Mechanisms of Action: Chemical vs Physical

Chemical blowing agents generate gases through thermal decomposition or chemical reactions, releasing gases such as nitrogen, carbon dioxide, or water vapor that expand and create cellular structures within polymers. Physical blowing agents rely on the vaporization or expansion of volatile liquids or gases under reduced pressure or increased temperature to form bubbles and foam. The distinction lies in chemical agents producing gases via intrinsic chemical transformations, while physical agents utilize phase changes or pressure differentials without altering the chemical composition.

Common Types and Examples

Chemical blowing agents commonly include azodicarbonamide, sodium bicarbonate, and hydrazine derivatives, which decompose under heat to release gases like nitrogen or carbon dioxide, creating foam structures in plastics and rubbers. Physical blowing agents often involve volatile liquids such as pentane, cyclopentane, or hydrofluorocarbons that evaporate upon pressure or temperature changes, forming gas bubbles within the material. You can choose between these agents based on desired foam properties, processing conditions, and environmental considerations.

Applications in Industry

Chemical blowing agents are extensively used in the production of polyurethane foams for insulation, automotive components, and packaging materials due to their ability to generate gas through thermal decomposition. Physical blowing agents find primary applications in polystyrene foam manufacturing, refrigeration insulation, and aerosol propellants by evaporating volatile liquids under controlled conditions. Both agents play critical roles in lightweight material fabrication, enhancing thermal insulation and reducing material density in various industrial sectors.

Environmental Impact and Safety

Chemical blowing agents release gases through chemical reactions, often producing greenhouse gases like CO2 or HFCs, which can contribute to global warming and ozone depletion. Physical blowing agents typically use volatile substances or gases that evaporate under heat, posing risks of flammability and toxicity but often have a lower long-term environmental footprint if non-ozone-depleting and low GWP substances are selected. Safety concerns for chemical agents include handling reactive chemicals that may cause burns or respiratory issues, while physical agents require careful control of pressure and temperature to prevent explosions or leaks.

Performance Comparison and Efficiency

Chemical blowing agents generate gas through thermal decomposition, offering consistent cell structure and improved thermal insulation in foam production, whereas physical blowing agents rely on phase change or vaporization, providing rapid foam expansion with lower environmental impact. Chemical agents typically yield higher foam density and enhanced mechanical strength, while physical agents enable better control over cell size distribution and reduced emissions. Efficiency in foam manufacturing depends on the specific application, with chemical blowing agents favored for rigid foams and physical agents preferred in flexible or low-impact applications.

Cost Considerations

Chemical blowing agents generally incur higher production costs due to raw material expenses and complex manufacturing processes, but they offer consistent foam cell structure and expansion rates. Physical blowing agents tend to be more cost-effective, leveraging gases like pentane or CO2, yet require stringent handling and containment measures that can elevate operational costs. Your choice between chemical and physical blowing agents should weigh initial material costs against long-term process control and safety requirements.

Future Trends in Blowing Agent Technology

Future trends in blowing agent technology emphasize the development of eco-friendly solutions, with chemical blowing agents evolving to utilize biodegradable compounds and lower greenhouse gas emissions. Physical blowing agents are advancing through the adoption of hydrofluoroolefins (HFOs) and supercritical CO2 techniques, reducing environmental impact while enhancing foam insulation properties. Innovations in nanotechnology and bio-based materials are also driving the creation of hybrid blowing agents that offer improved thermal performance and sustainability for industrial applications.

Chemical Blowing Agent vs Physical Blowing Agent Infographic

libmatt.com

libmatt.com