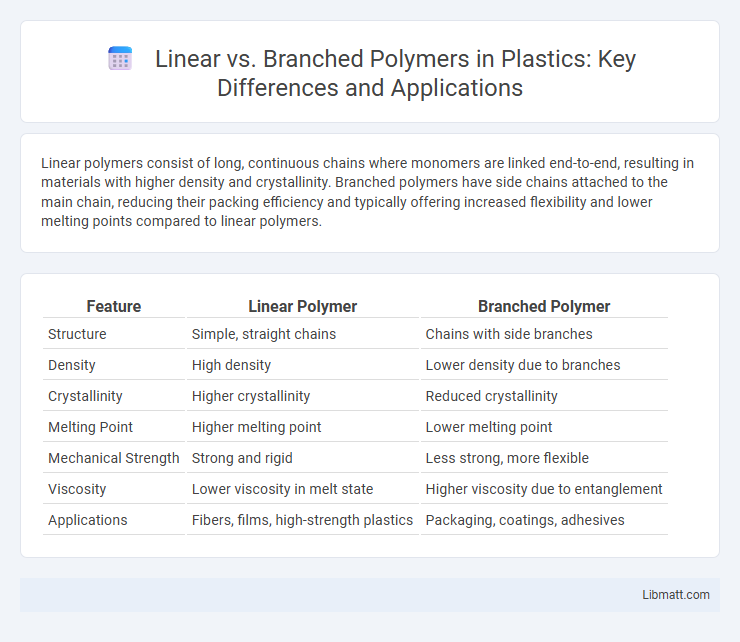

Linear polymers consist of long, continuous chains where monomers are linked end-to-end, resulting in materials with higher density and crystallinity. Branched polymers have side chains attached to the main chain, reducing their packing efficiency and typically offering increased flexibility and lower melting points compared to linear polymers.

Table of Comparison

| Feature | Linear Polymer | Branched Polymer |

|---|---|---|

| Structure | Simple, straight chains | Chains with side branches |

| Density | High density | Lower density due to branches |

| Crystallinity | Higher crystallinity | Reduced crystallinity |

| Melting Point | Higher melting point | Lower melting point |

| Mechanical Strength | Strong and rigid | Less strong, more flexible |

| Viscosity | Lower viscosity in melt state | Higher viscosity due to entanglement |

| Applications | Fibers, films, high-strength plastics | Packaging, coatings, adhesives |

Introduction to Linear and Branched Polymers

Linear polymers consist of long, continuous chains of repeating units connected end-to-end, resulting in a straightforward, unbranched structure. Branched polymers have side chains attached to the main polymer backbone, creating a more complex, tree-like architecture that influences properties such as density and melting point. Understanding the differences between linear and branched polymers helps you select materials with the desired mechanical and chemical characteristics for various applications.

Structural Differences: Linear vs Branched Polymers

Linear polymers consist of long, continuous chains of repeating units without side branches, resulting in a more ordered and tightly packed structure. Branched polymers have side chains attached to the main polymer backbone, creating a less dense and more irregular molecular arrangement. Understanding the structural differences helps you predict properties like melting point, solubility, and mechanical strength.

Synthesis Methods of Linear and Branched Polymers

Linear polymers are primarily synthesized through step-growth polymerization and chain-growth polymerization methods, where monomers link end-to-end forming long, unbranched chains. Branched polymers are typically produced via controlled radical polymerization techniques, such as atom transfer radical polymerization (ATRP) or reversible addition-fragmentation chain transfer (RAFT), which allow introduction of branching points during polymer growth. Copolymerization strategies and the use of multifunctional monomers enable the formation of branched architectures with varied branch density and length.

Molecular Weight and Polymer Architecture

Linear polymers consist of long, unbranched chains with molecular weights directly influencing properties like tensile strength and melting point, as their architecture allows dense packing and crystallinity. Branched polymers have side chains attached to the main backbone, which reduces chain packing efficiency and results in lower density and melting temperature despite similar molecular weights. The polymer architecture drastically impacts molecular weight distribution and physical behavior, with branched structures often exhibiting more amorphous characteristics and increased solubility compared to linear counterparts.

Physical Properties Comparison

Linear polymers exhibit higher density and crystallinity due to their orderly chain alignment, resulting in greater tensile strength and melting points compared to branched polymers. Branched polymers have lower density and reduced crystallinity because the branches prevent tight packing, leading to increased flexibility and impact resistance. The presence of branches also decreases the polymer's viscosity, making branched polymers easier to process and mold than linear polymers.

Mechanical Strength: Linear vs Branched

Branched polymers typically exhibit lower mechanical strength compared to linear polymers due to their irregular structure, which hinders efficient chain packing and reduces crystallinity. Linear polymers have higher tensile strength and modulus because their chains align closely, facilitating strong intermolecular forces and dense packing. This structural difference directly impacts applications requiring high durability and resistance to deformation.

Thermal Stability and Resistance

Linear polymers exhibit moderate thermal stability due to their orderly and closely packed chain structure, allowing some degree of heat resistance before degradation occurs. Branched polymers, with their irregular architecture and increased free volume, often provide enhanced thermal resistance by disrupting crystallinity and reducing heat conduction pathways. The molecular branching in branched polymers generally improves thermal stability by hindering chain mobility and delaying thermal decomposition compared to linear polymers.

Processability and Applications

Linear polymers exhibit higher processability due to their ability to easily align and melt, making them ideal for applications such as fibers, films, and packaging materials. Branched polymers, with their tangled molecular structure, offer enhanced impact resistance and elasticity, suitable for coatings, adhesives, and elastomers. Your choice between linear and branched polymers directly influences the manufacturing method and end-use performance of the product.

Environmental Impact and Degradability

Linear polymers generally exhibit higher crystallinity and density, affecting their environmental impact by making them less permeable but slower to degrade. Branched polymers have a more irregular structure, increasing their surface area and enhancing microbial access, which can improve their biodegradability. Understanding these differences helps you choose materials with a lower ecological footprint based on specific degradation rates and environmental persistence.

Future Trends in Polymer Research

Future trends in polymer research emphasize the development of hybrid materials combining linear and branched polymer architectures to enhance mechanical strength and thermal stability. Advances in controlled polymerization techniques enable precise tuning of polymer branching, leading to customizable properties for specialized applications like biomedicine and electronics. Emerging sustainable polymers focus on bio-based linear and branched structures, aiming to reduce environmental impact while maintaining high performance.

Linear vs branched polymer Infographic

libmatt.com

libmatt.com