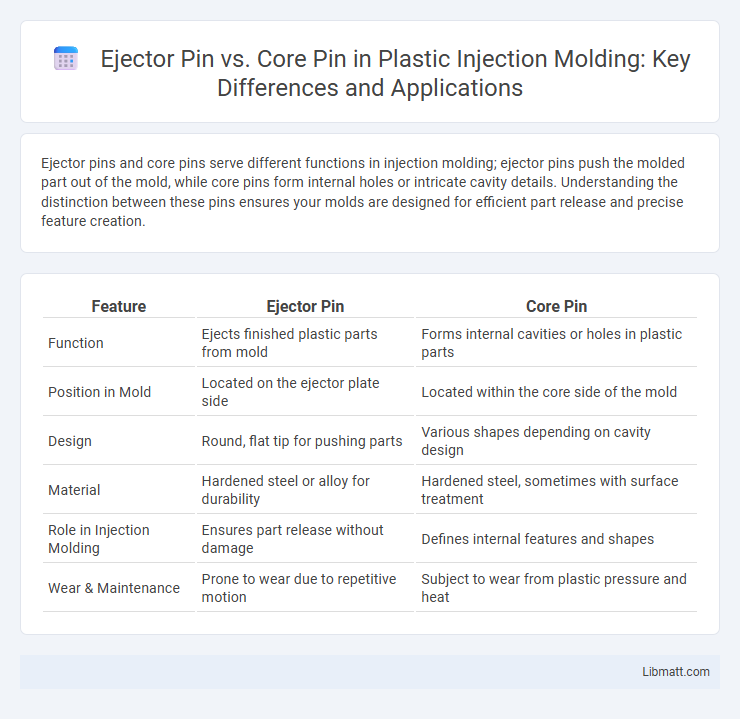

Ejector pins and core pins serve different functions in injection molding; ejector pins push the molded part out of the mold, while core pins form internal holes or intricate cavity details. Understanding the distinction between these pins ensures your molds are designed for efficient part release and precise feature creation.

Table of Comparison

| Feature | Ejector Pin | Core Pin |

|---|---|---|

| Function | Ejects finished plastic parts from mold | Forms internal cavities or holes in plastic parts |

| Position in Mold | Located on the ejector plate side | Located within the core side of the mold |

| Design | Round, flat tip for pushing parts | Various shapes depending on cavity design |

| Material | Hardened steel or alloy for durability | Hardened steel, sometimes with surface treatment |

| Role in Injection Molding | Ensures part release without damage | Defines internal features and shapes |

| Wear & Maintenance | Prone to wear due to repetitive motion | Subject to wear from plastic pressure and heat |

Introduction to Ejector Pin and Core Pin

Ejector pins and core pins are essential components in the injection molding process, each serving distinct purposes. Ejector pins are used to push the molded part out of the mold cavity after cooling, ensuring smooth removal and preventing damage to the finished product. Core pins, on the other hand, are inserted into the mold to create holes, recesses, or intricate internal features, shaping the internal geometry of the molded part.

Definition of Ejector Pin

An ejector pin is a crucial component in injection molding designed to push the molded part out of the mold cavity after cooling, ensuring smooth release without damage. Core pins, on the other hand, form internal shapes or holes within the molded product. Understanding the function of ejector pins helps you optimize mold design for efficient part ejection and quality control.

Definition of Core Pin

A core pin is a precision-engineered component used in injection molding to create detailed internal features or hollow sections within a molded part. Unlike an ejector pin, which pushes the finished product out of the mold, a core pin forms cavities or holes during the molding process. The core pin's design directly influences the accuracy and surface finish of complex internal geometries in plastic or metal injection molded components.

Key Functions of Ejector Pin

Ejector pins are essential components in injection molding, responsible for pushing the finished part out of the mold cavity after cooling. These pins ensure smooth ejection to prevent damage or deformation to the molded part, maintaining high production quality and efficiency. Your manufacturing process relies on precise ejector pin design to optimize cycle times and reduce downtime.

Key Functions of Core Pin

Core pins play a crucial role in injection molding by forming internal features and undercuts within a molded part, ensuring precise cavity shapes. Unlike ejector pins that primarily push finished parts out of the mold, core pins maintain the mold's internal geometry during the injection process. Their key functions include shaping hollow sections, creating holes, and providing structural integrity to intricate mold designs.

Material Differences Between Ejector Pin and Core Pin

Ejector pins are commonly made from high-carbon steel or hardened tool steel to withstand repeated impact and wear during the ejection process, while core pins typically use alloy tool steels or stainless steel to maintain dimensional accuracy and resist corrosion. The material for ejector pins prioritizes toughness and hardness to prevent deformation, whereas core pins emphasize strength and thermal stability to endure molding pressures and temperature fluctuations. Understanding these material differences helps you choose the right component to ensure durability and precision in injection molding applications.

Design Considerations for Ejector and Core Pins

Design considerations for ejector pins prioritize durability and precise alignment to ensure consistent part ejection without deformation or damage, often requiring hardened steel and smooth finishes for wear resistance. Core pins are designed with attention to thermal conductivity and dimensional stability, as they shape internal cavities and must withstand high injection pressures and temperatures. Both pins require careful material selection and dimensional accuracy to maintain mold integrity and optimize cycle times in injection molding processes.

Applications in Injection Molding

Ejector pins and core pins serve distinct functions in injection molding, with ejector pins primarily used to push the molded part out of the mold after cooling, ensuring smooth ejection without damaging the product. Core pins shape internal features or cavities within the molded part by forming precise holes or intricate details, essential for complex geometries in parts like plastic housings or connectors. Understanding their specific applications enhances mold design efficiency and improves the overall quality of injection-molded components.

Advantages and Disadvantages Comparison

Ejector pins excel in efficiently pushing finished parts out of molds, reducing cycle time and minimizing damage risk during ejection, but they can cause visible pin marks on your product surface. Core pins offer precise shaping and help form internal cavities with high accuracy, though they tend to increase mold complexity and production costs. Choosing between ejector pins and core pins depends on your part design requirements, balancing the trade-offs between surface finish quality and mold manufacturing intricacy.

How to Choose Between Ejector Pin and Core Pin

Choosing between an ejector pin and a core pin depends on their distinct functions in injection molding; ejector pins primarily eject the molded part from the mold, while core pins form internal cavities or detailed features within the part. Material selection, size, and positioning must consider mold design and part geometry to ensure optimal molding performance and part quality. Evaluating part complexity and the need for internal features versus ejection mechanisms guides the decision for using core pins or ejector pins.

Ejector Pin vs Core Pin Infographic

libmatt.com

libmatt.com