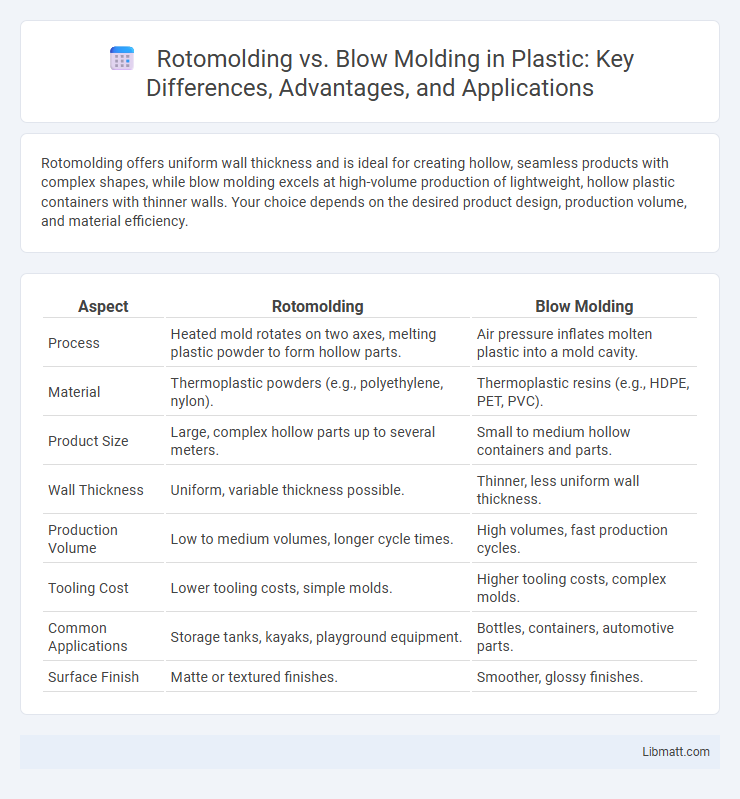

Rotomolding offers uniform wall thickness and is ideal for creating hollow, seamless products with complex shapes, while blow molding excels at high-volume production of lightweight, hollow plastic containers with thinner walls. Your choice depends on the desired product design, production volume, and material efficiency.

Table of Comparison

| Aspect | Rotomolding | Blow Molding |

|---|---|---|

| Process | Heated mold rotates on two axes, melting plastic powder to form hollow parts. | Air pressure inflates molten plastic into a mold cavity. |

| Material | Thermoplastic powders (e.g., polyethylene, nylon). | Thermoplastic resins (e.g., HDPE, PET, PVC). |

| Product Size | Large, complex hollow parts up to several meters. | Small to medium hollow containers and parts. |

| Wall Thickness | Uniform, variable thickness possible. | Thinner, less uniform wall thickness. |

| Production Volume | Low to medium volumes, longer cycle times. | High volumes, fast production cycles. |

| Tooling Cost | Lower tooling costs, simple molds. | Higher tooling costs, complex molds. |

| Common Applications | Storage tanks, kayaks, playground equipment. | Bottles, containers, automotive parts. |

| Surface Finish | Matte or textured finishes. | Smoother, glossy finishes. |

Introduction to Rotomolding and Blow Molding

Rotomolding, or rotational molding, is a manufacturing process that produces hollow, seamless plastic parts by heating and rotating a mold filled with powdered resin. Blow molding involves inflating heated plastic inside a mold to create hollow shapes, commonly used for bottles and containers. Choosing between rotomolding and blow molding depends on your product's complexity, volume, and material requirements.

Key Differences Between Rotomolding and Blow Molding

Rotomolding and blow molding differ primarily in manufacturing processes; rotomolding involves heating and rotating a mold to evenly coat the interior with molten plastic, while blow molding inflates heated plastic inside a mold to form hollow parts. Rotomolding excels in producing large, hollow, seamless products with uniform wall thickness, whereas blow molding is ideal for high-volume production of thinner-walled containers like bottles. Your choice should consider material efficiency, production speed, and design complexity, as rotomolding offers greater design flexibility and durability, but blow molding provides faster cycle times and cost-effectiveness for simpler shapes.

Material Compatibility in Rotomolding vs Blow Molding

Rotomolding offers superior material compatibility by utilizing thermoplastic powders such as polyethylene, polypropylene, and nylon, allowing for uniform wall thickness and stress-free parts. Blow molding primarily works with thermoplastics like HDPE, LDPE, PET, and PVC, excelling in producing hollow parts with high throughput but limited to materials with appropriate melt strength. The rotational molding process supports a wider range of high-viscosity and multi-layer compounds, while blow molding requires precise melt flow properties to ensure proper parison formation and consistent part quality.

Manufacturing Process Comparison

Rotomolding uses a heated mold filled with polymer powder that rotates biaxially to coat the interior, forming a seamless, stress-free part ideal for large, hollow shapes. Blow molding involves extruding or injection molding a parison, then inflating it inside a mold to create hollow plastic parts with consistent wall thickness, favored for high-volume production of bottles and containers. Rotomolding offers lower production speeds and design flexibility, while blow molding delivers faster cycle times and greater precision for complex geometries.

Product Design Capabilities

Rotomolding offers superior design flexibility, allowing for complex shapes, uniform wall thickness, and integrated features like ribs or bosses without seams. Blow molding excels in producing hollow parts quickly with thinner walls but is limited in intricate detailing compared to rotomolding. Your choice depends on the required design complexity and functional characteristics of the final product.

Cost Efficiency: Rotomolding vs Blow Molding

Rotomolding offers superior cost efficiency for low to medium production volumes due to lower tooling expenses and minimal material waste, making it ideal for custom and complex shapes. Blow molding provides greater cost advantages in high-volume production runs with faster cycle times and automation, reducing per-unit costs significantly. Your choice depends on balancing initial investment against expected production scale to maximize cost efficiency.

Surface Finish and Aesthetic Properties

Rotomolding offers a seamless, uniform surface finish with minimal weld lines, resulting in smoother aesthetics ideal for complex shapes and larger parts. Blow molding often produces visible seams and less consistent surface textures due to the mold clamping process, suitable for high-volume items with simpler designs. Your choice between rotomolding and blow molding significantly impacts the visual appeal and tactile quality of the final product.

Strength and Durability of Finished Products

Rotomolding produces parts with uniform wall thickness and fewer weak points, resulting in superior strength and durability compared to blow molding. Blow molding often creates thinner walls and seams that can be prone to stress and impact damage over time. Your choice of rotomolding can ensure finished products withstand harsh conditions and heavy use more reliably.

Environmental Impact and Sustainability

Rotomolding produces minimal waste due to precise material usage and offers longer-lasting, recyclable products, making it more environmentally friendly than blow molding, which generates more scrap and energy consumption. Rotomolded items often use polyethylene, which is easily recyclable, reducing landfill impact, whereas blow molding typically involves higher energy processes and potential for more emissions. Choosing rotomolding can enhance your sustainability efforts by lowering overall environmental impact across the product lifecycle.

Choosing the Right Process for Your Application

Rotomolding offers superior design flexibility and uniform wall thickness, making it ideal for complex, hollow shapes and low-to-medium production volumes. Blow molding excels in high-volume manufacturing with faster cycle times and is best suited for producing lightweight, hollow parts such as bottles and containers. Understanding your application's requirements for part complexity, production volume, and material properties will guide you in selecting the right molding process.

Rotomolding vs blow molding Infographic

libmatt.com

libmatt.com