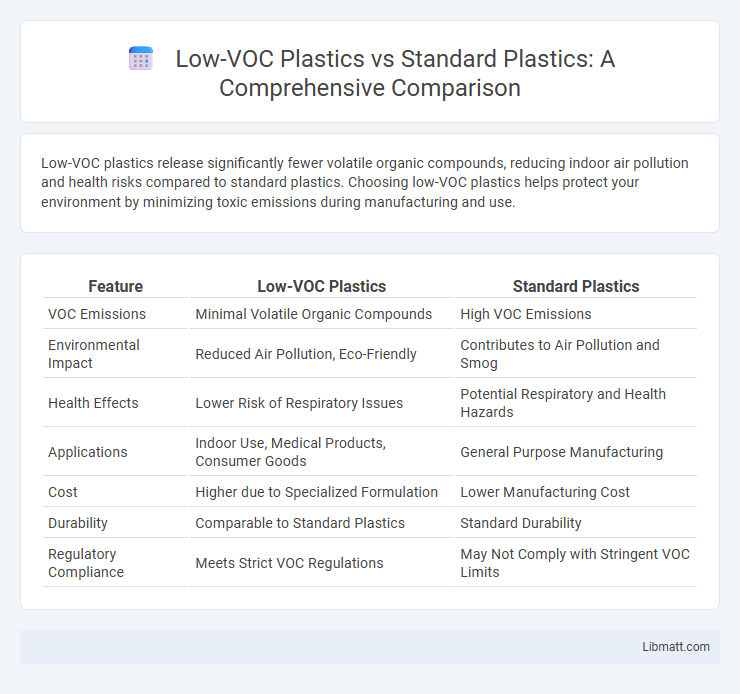

Low-VOC plastics release significantly fewer volatile organic compounds, reducing indoor air pollution and health risks compared to standard plastics. Choosing low-VOC plastics helps protect your environment by minimizing toxic emissions during manufacturing and use.

Table of Comparison

| Feature | Low-VOC Plastics | Standard Plastics |

|---|---|---|

| VOC Emissions | Minimal Volatile Organic Compounds | High VOC Emissions |

| Environmental Impact | Reduced Air Pollution, Eco-Friendly | Contributes to Air Pollution and Smog |

| Health Effects | Lower Risk of Respiratory Issues | Potential Respiratory and Health Hazards |

| Applications | Indoor Use, Medical Products, Consumer Goods | General Purpose Manufacturing |

| Cost | Higher due to Specialized Formulation | Lower Manufacturing Cost |

| Durability | Comparable to Standard Plastics | Standard Durability |

| Regulatory Compliance | Meets Strict VOC Regulations | May Not Comply with Stringent VOC Limits |

Introduction to Low-VOC and Standard Plastics

Low-VOC plastics release significantly fewer volatile organic compounds compared to standard plastics, reducing harmful emissions and improving indoor air quality. You can choose low-VOC plastics for eco-friendly applications, as they contribute less to environmental pollution and health risks. Standard plastics, while commonly used for their durability and cost-effectiveness, often emit higher levels of VOCs during production and disposal.

What are VOCs in Plastics?

VOCs, or volatile organic compounds, in plastics are chemicals that easily evaporate at room temperature, contributing to air pollution and potential health risks. Low-VOC plastics emit significantly fewer of these compounds, reducing indoor air contamination and exposure to toxic fumes. Standard plastics often release higher levels of VOCs during manufacturing and use, impacting environmental quality and human health.

Key Differences Between Low-VOC and Standard Plastics

Low-VOC plastics contain significantly fewer volatile organic compounds compared to standard plastics, resulting in reduced off-gassing and improved indoor air quality. They are typically manufactured using environmentally friendly additives and processes that minimize harmful emissions during production and use. Your choice of low-VOC plastics can contribute to healthier environments, especially in applications requiring strict air quality standards.

Health Impacts of VOC Emissions

Low-VOC plastics release significantly fewer volatile organic compounds (VOCs), reducing indoor air pollution and minimizing respiratory issues such as asthma and allergies. Standard plastics emit higher levels of VOCs, which contribute to headaches, dizziness, and long-term health risks including liver and kidney damage. Choosing low-VOC plastics improves air quality and decreases exposure to toxic chemical residues harmful to human health.

Environmental Effects of VOCs from Plastics

Low-VOC plastics significantly reduce the emission of volatile organic compounds (VOCs), which are harmful pollutants contributing to smog formation and indoor air quality degradation. Standard plastics often release higher levels of VOCs during production, use, and disposal, leading to increased environmental toxicity and health risks. Choosing low-VOC plastics helps minimize your carbon footprint while supporting cleaner air and safer ecosystems.

Applications of Low-VOC Plastics

Low-VOC plastics are widely used in medical devices, food packaging, and automotive interiors due to their reduced emission of volatile organic compounds, enhancing indoor air quality and safety. These plastics are preferred in consumer electronics and household products where minimizing off-gassing is critical for health compliance and user comfort. Low-VOC materials also find applications in construction and building materials, supporting green building certifications and stringent environmental regulations.

Performance Comparison: Low-VOC vs Standard Plastics

Low-VOC plastics demonstrate comparable mechanical strength and durability to standard plastics while significantly reducing harmful volatile organic compound emissions during use and processing. These materials enhance indoor air quality and comply with stricter environmental regulations without compromising product performance. Your choice of low-VOC plastics supports sustainable manufacturing and healthier environments.

Regulatory Standards for VOCs in Plastics

Regulatory standards for VOCs in plastics vary globally, with agencies like the EPA in the United States and the European Chemicals Agency enforcing strict limits on VOC emissions to reduce environmental and health impacts. Low-VOC plastics comply with these regulations by using alternative materials and additives that minimize volatile organic compound release, ensuring safer indoor air quality and usage. Understanding these standards helps you choose compliant and eco-friendly plastic products that meet current environmental guidelines.

Market Trends and Consumer Demand for Low-VOC Plastics

The market for low-VOC plastics is expanding rapidly as consumer demand shifts toward environmentally friendly and health-conscious products, driven by increased awareness of chemical emissions associated with standard plastics. Regulatory pressures and corporate sustainability initiatives are accelerating the adoption of low-VOC alternatives across industries such as packaging, automotive, and electronics. Market research indicates a growing preference for low-VOC plastics due to their reduced impact on indoor air quality and overall human health, fostering innovation in biodegradable and recycled material formulations.

Future Outlook: Advancements in Low-VOC Plastic Technology

Advancements in low-VOC plastic technology are driving significant improvements in environmental safety and manufacturing efficiency, with innovative additives and bio-based polymers reducing volatile organic compound emissions. Emerging techniques such as advanced polymerization and nanocomposite integration enhance durability while maintaining low VOC levels, positioning these plastics as a key element in sustainable packaging and automotive industries. Ongoing research aims to optimize cost-effectiveness and recyclability, forecasting increased adoption of low-VOC plastics in global markets by 2030.

Low-VOC Plastics vs Standard Plastics Infographic

libmatt.com

libmatt.com