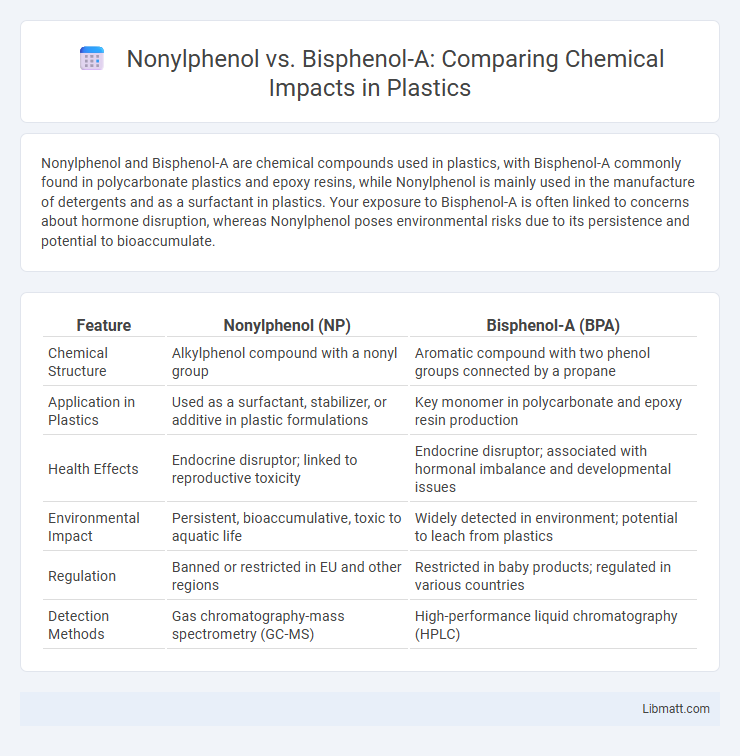

Nonylphenol and Bisphenol-A are chemical compounds used in plastics, with Bisphenol-A commonly found in polycarbonate plastics and epoxy resins, while Nonylphenol is mainly used in the manufacture of detergents and as a surfactant in plastics. Your exposure to Bisphenol-A is often linked to concerns about hormone disruption, whereas Nonylphenol poses environmental risks due to its persistence and potential to bioaccumulate.

Table of Comparison

| Feature | Nonylphenol (NP) | Bisphenol-A (BPA) |

|---|---|---|

| Chemical Structure | Alkylphenol compound with a nonyl group | Aromatic compound with two phenol groups connected by a propane |

| Application in Plastics | Used as a surfactant, stabilizer, or additive in plastic formulations | Key monomer in polycarbonate and epoxy resin production |

| Health Effects | Endocrine disruptor; linked to reproductive toxicity | Endocrine disruptor; associated with hormonal imbalance and developmental issues |

| Environmental Impact | Persistent, bioaccumulative, toxic to aquatic life | Widely detected in environment; potential to leach from plastics |

| Regulation | Banned or restricted in EU and other regions | Restricted in baby products; regulated in various countries |

| Detection Methods | Gas chromatography-mass spectrometry (GC-MS) | High-performance liquid chromatography (HPLC) |

Introduction to Nonylphenol and Bisphenol-A

Nonylphenol and Bisphenol-A (BPA) are industrial chemicals commonly used in plastic manufacturing, with Nonylphenol primarily found in detergents and rubber production, while BPA is a key component in polycarbonate plastics and epoxy resins. Nonylphenol is recognized for its endocrine-disrupting properties and environmental persistence, leading to regulatory restrictions in many regions. BPA is chiefly scrutinized for its hormone-mimicking effects, resulting in widespread efforts to reduce its presence in food packaging and consumer products.

Chemical Structures and Properties

Nonylphenol and Bisphenol-A are distinct chemical compounds used in plastics, with Nonylphenol featuring a phenol group bonded to a nonyl chain, giving it hydrophobic characteristics and endocrine-disrupting potential. Bisphenol-A consists of two phenol groups connected by a propane bridge, resulting in a rigid molecular structure that contributes to the durability and heat resistance of polycarbonate plastics and epoxy resins. Understanding the differences in their chemical structures and properties helps you evaluate their impact on plastic performance and environmental safety.

Common Uses in Plastics Manufacturing

Nonylphenol is commonly used as a stabilizer and surfactant in plastics manufacturing, particularly in the production of polyvinyl chloride (PVC) and epoxy resins. Bisphenol-A (BPA) serves as a key monomer in producing polycarbonate plastics and epoxy resins, which are widely used in food and beverage containers, electronics, and automotive parts. Both chemicals play crucial roles in enhancing plastic durability and flexibility but are increasingly scrutinized due to their environmental and health impacts.

Mechanisms of Release from Plastic Products

Nonylphenol releases from plastics primarily through hydrolysis of nonylphenol ethoxylates used as surfactants, facilitated by environmental factors like heat, UV exposure, and microbial activity. Bisphenol-A migrates from polycarbonate and epoxy resins via polymer degradation and leaching, especially under high temperatures or acidic conditions. Both chemicals exhibit potential for bioaccumulation and endocrine disruption due to their persistent release from consumer plastic products.

Potential Human Health Risks

Nonylphenol and Bisphenol-A (BPA) are industrial chemicals commonly found in plastics, both linked to endocrine disruption in humans. Nonylphenol exposure can interfere with hormone function, potentially affecting reproductive health and increasing the risk of developmental disorders. BPA is associated with adverse effects on the brain, behavior, and prostate gland of fetuses, infants, and children, raising concerns about obesity, diabetes, and cardiovascular disease later in life.

Environmental Impact and Persistence

Nonylphenol and Bisphenol-A (BPA) are both endocrine-disrupting chemicals commonly found in plastics, but nonylphenol exhibits greater environmental persistence, accumulating in aquatic ecosystems and posing long-term risks to wildlife. Bisphenol-A, while also harmful, tends to degrade more rapidly in the environment but still contributes significantly to pollution due to its widespread use in polycarbonate plastics and epoxy resins. Understanding the distinct environmental impacts and persistence of these compounds helps you make informed choices about plastic products to reduce ecological harm.

Regulatory Guidelines and Restrictions

Nonylphenol and Bisphenol-A (BPA) face stringent regulatory guidelines due to their endocrine-disrupting properties, with the European Union restricting nonylphenol in detergents and plastics under REACH regulations. BPA is heavily regulated worldwide, including bans on its use in baby bottles across the EU, Canada, and the U.S., alongside specific limits for food contact materials set by the FDA and EFSA. These regulatory measures aim to reduce human exposure by enforcing strict migration limits and monitoring compliance in consumer products.

Comparisons in Toxicity Levels

Nonylphenol exhibits higher toxicity in aquatic environments due to its persistence and endocrine-disrupting effects, often accumulating in marine organisms. Bisphenol-A (BPA) shows significant estrogenic activity linked to hormonal imbalances and developmental issues in humans, though it degrades more rapidly in the environment. Your exposure to BPA can pose risks through food and beverage containers, while nonylphenol primarily affects wildlife through industrial discharge.

Alternatives and Safer Substitutes

Nonylphenol and Bisphenol-A (BPA) are chemicals commonly found in plastics, linked to environmental and health concerns due to their endocrine-disrupting properties. Safer substitutes such as polyethylene terephthalate (PET), polypropylene (PP), and bioplastics derived from plant materials offer alternatives free from these harmful compounds. Choosing plastics without Nonylphenol and BPA helps reduce exposure risks and supports sustainable manufacturing practices.

Future Outlook in Plastic Production

Nonylphenol and Bisphenol-A (BPA) are increasingly scrutinized due to their endocrine-disrupting properties, prompting regulatory pressures and market shifts toward safer plastic alternatives. Innovations in biobased and non-toxic additives aim to replace these chemicals, driving advancements in sustainable plastic production and circular economy models. Industry trends indicate a growing demand for BPA-free and nonylphenol-free plastics to meet stricter environmental standards and consumer preferences for eco-friendly materials.

Nonylphenol vs Bisphenol-A in Plastics Infographic

libmatt.com

libmatt.com