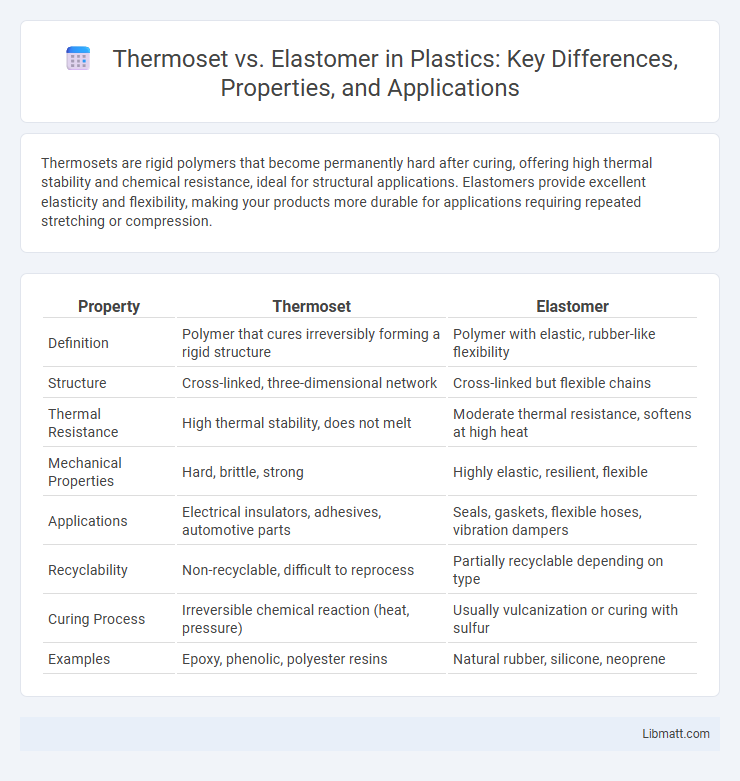

Thermosets are rigid polymers that become permanently hard after curing, offering high thermal stability and chemical resistance, ideal for structural applications. Elastomers provide excellent elasticity and flexibility, making your products more durable for applications requiring repeated stretching or compression.

Table of Comparison

| Property | Thermoset | Elastomer |

|---|---|---|

| Definition | Polymer that cures irreversibly forming a rigid structure | Polymer with elastic, rubber-like flexibility |

| Structure | Cross-linked, three-dimensional network | Cross-linked but flexible chains |

| Thermal Resistance | High thermal stability, does not melt | Moderate thermal resistance, softens at high heat |

| Mechanical Properties | Hard, brittle, strong | Highly elastic, resilient, flexible |

| Applications | Electrical insulators, adhesives, automotive parts | Seals, gaskets, flexible hoses, vibration dampers |

| Recyclability | Non-recyclable, difficult to reprocess | Partially recyclable depending on type |

| Curing Process | Irreversible chemical reaction (heat, pressure) | Usually vulcanization or curing with sulfur |

| Examples | Epoxy, phenolic, polyester resins | Natural rubber, silicone, neoprene |

Introduction to Thermosets and Elastomers

Thermosets are polymers that undergo a chemical curing process forming rigid, heat-resistant materials widely used in automotive and aerospace industries due to their high mechanical strength and thermal stability. Elastomers are highly elastic polymers capable of significant reversible deformation, making them ideal for applications like seals, gaskets, and flexible molds in the manufacturing sector. Both materials offer distinct performance characteristics driven by their molecular structure, with thermosets providing rigidity and elastomers offering elasticity.

Chemical Structure Comparison

Thermosets possess a densely cross-linked polymer network, resulting in a rigid, three-dimensional structure that provides high thermal and chemical resistance. Elastomers feature loosely cross-linked, flexible polymer chains allowing significant elastic deformation and recovery after stress. The key difference lies in the degree and nature of cross-linking, influencing their mechanical behavior and thermal properties.

Key Properties of Thermosets

Thermosets exhibit high thermal stability, excellent chemical resistance, and superior mechanical strength, making them ideal for durable applications that require heat resistance and structural integrity. Their rigid polymer networks form irreversible bonds during curing, preventing remelting or reshaping, which ensures long-term performance under stress. You can rely on thermosets for components that must withstand harsh environments without losing their shape or properties.

Distinctive Features of Elastomers

Elastomers exhibit unique characteristics such as high elasticity, resilience, and the ability to undergo significant deformation without permanent shape change, making them ideal for flexible applications. Their molecular structure consists of long polymer chains with weak intermolecular forces, enabling reversible stretching and recovery. Unlike thermosets, elastomers do not harden permanently after curing, retaining their rubber-like flexibility across a wide temperature range.

Manufacturing Processes

Thermosets are manufactured through curing processes involving heat or chemical reactions that create strong, inflexible cross-linked polymer chains, resulting in durable and heat-resistant products. Elastomers, by contrast, are produced using vulcanization or cross-linking methods that provide elasticity and flexibility, ideal for applications requiring stretch and recovery. Understanding your specific manufacturing needs helps determine whether thermoset rigidity or elastomer flexibility best suits your project.

Mechanical Performance Differences

Thermosets exhibit higher rigidity and dimensional stability due to their cross-linked polymer chains, resulting in superior mechanical strength and resistance to deformation under load. Elastomers, characterized by their flexible and loosely cross-linked structures, provide exceptional elasticity and resilience, allowing your materials to stretch and recover without permanent deformation. Choosing between thermoset and elastomer depends on whether your application demands durable structural support or flexible, impact-absorbing performance.

Common Applications

Thermosets find widespread application in automotive components, electrical insulation, and aerospace parts due to their strong, heat-resistant properties. Elastomers are commonly used in seals, gaskets, tires, and flexible hoses where elasticity and durability are essential. Both materials are critical in manufacturing industries, with thermosets favored for rigid, high-performance uses and elastomers for flexible, impact-absorbing applications.

Advantages and Limitations

Thermosets offer superior thermal stability, chemical resistance, and mechanical strength, making them ideal for high-temperature applications and structural components. Elastomers provide excellent flexibility, elasticity, and impact resistance, suitable for sealing, cushioning, and vibration absorption. Limitations include thermosets' brittleness and inability to be reshaped after curing, while elastomers generally have lower mechanical strength and can degrade under prolonged heat exposure.

Environmental Considerations

Thermosets offer high durability and chemical resistance, making them less prone to degradation and leaching, but their cross-linked structure hinders recycling and often leads to landfill disposal. Elastomers provide flexibility and can be formulated for biodegradability, yet many synthetic variants contribute to microplastic pollution and have limited end-of-life options. Advances in bio-based thermosets and recyclable elastomers are critical to reducing environmental impact in polymer applications.

Choosing Between Thermosets and Elastomers

Choosing between thermosets and elastomers depends on the specific application requirements such as temperature resistance, flexibility, and durability. Thermosets, characterized by their rigid, heat-resistant structure, provide excellent mechanical strength and chemical stability, making them ideal for high-stress environments. Elastomers offer superior elasticity and resilience, perfect for applications requiring flexibility, impact absorption, and repetitive stretching without permanent deformation.

Thermoset vs elastomer Infographic

libmatt.com

libmatt.com