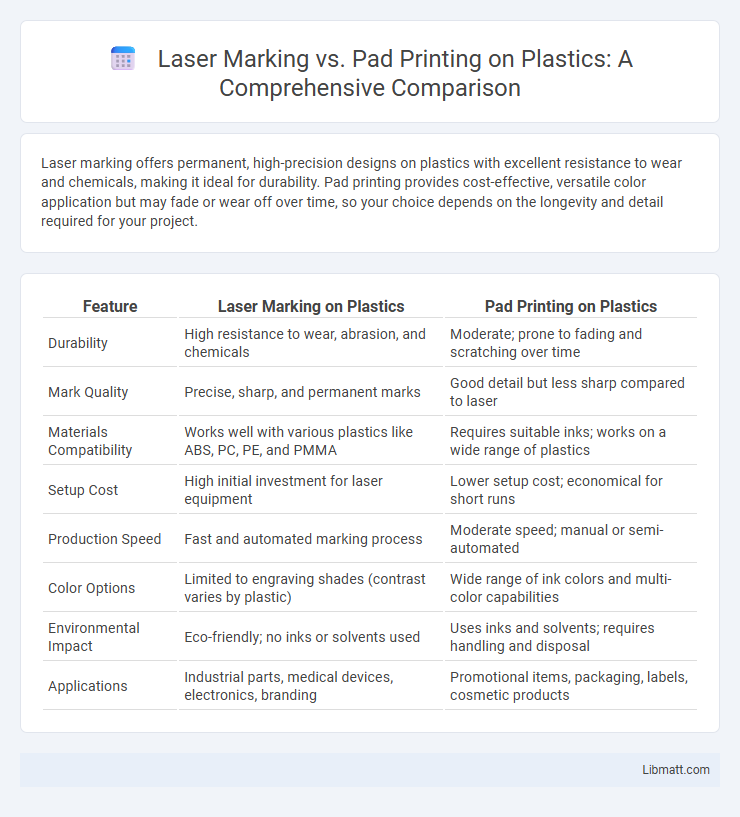

Laser marking offers permanent, high-precision designs on plastics with excellent resistance to wear and chemicals, making it ideal for durability. Pad printing provides cost-effective, versatile color application but may fade or wear off over time, so your choice depends on the longevity and detail required for your project.

Table of Comparison

| Feature | Laser Marking on Plastics | Pad Printing on Plastics |

|---|---|---|

| Durability | High resistance to wear, abrasion, and chemicals | Moderate; prone to fading and scratching over time |

| Mark Quality | Precise, sharp, and permanent marks | Good detail but less sharp compared to laser |

| Materials Compatibility | Works well with various plastics like ABS, PC, PE, and PMMA | Requires suitable inks; works on a wide range of plastics |

| Setup Cost | High initial investment for laser equipment | Lower setup cost; economical for short runs |

| Production Speed | Fast and automated marking process | Moderate speed; manual or semi-automated |

| Color Options | Limited to engraving shades (contrast varies by plastic) | Wide range of ink colors and multi-color capabilities |

| Environmental Impact | Eco-friendly; no inks or solvents used | Uses inks and solvents; requires handling and disposal |

| Applications | Industrial parts, medical devices, electronics, branding | Promotional items, packaging, labels, cosmetic products |

Introduction to Plastic Marking Technologies

Laser marking offers precise, permanent engravings on plastics by altering the material's surface with focused light, ensuring high durability and resistance to wear. Pad printing uses silicone pads to transfer ink onto plastic surfaces, suitable for colorful and detailed designs but less resistant to abrasion compared to laser marks. Your choice between these technologies depends on the required permanence, detail, and surface type of the plastic being marked.

Overview of Laser Marking

Laser marking on plastics utilizes a focused laser beam to create precise, permanent marks by altering the material's surface. This technique offers high-resolution text and graphics with excellent durability, resistant to wear, chemicals, and heat. You can achieve clean, intricate designs without inks or solvents, making laser marking an environmentally friendly and low-maintenance option compared to pad printing.

Overview of Pad Printing

Pad printing on plastics involves transferring ink from a silicone pad onto the surface, enabling precise and detailed designs on irregular or curved shapes. This method offers high versatility with a wide color palette and is cost-effective for large production runs, making it ideal for branding and product identification. Your choice depends on the required durability and detail; pad printing generally provides vibrant colors but lower wear resistance compared to laser marking.

Material Compatibility: Plastics

Laser marking on plastics offers high precision and durability, working best on materials like ABS, polycarbonate, and acrylic, where it creates permanent, high-contrast marks without inks or consumables. Pad printing suits a wider range of plastics, including polypropylene and polyethylene, allowing colorful and versatile designs but may wear off over time due to its ink-based process. You should choose laser marking for long-lasting, chemical-resistant identification, while pad printing is ideal for vibrant, multi-colored logos on varying plastic surfaces.

Marking Quality and Precision

Laser marking on plastics delivers superior marking quality and precision by creating high-resolution, permanent marks with sharp edges and consistent depth. Pad printing offers good quality but often lacks the fine detail and uniformity achievable with laser technology, especially on complex or curved surfaces. For applications demanding exactness and durability, laser marking ensures your branding or information remains clear and resistant to wear over time.

Speed and Production Efficiency

Laser marking offers significantly faster processing speeds compared to pad printing on plastics, enabling higher production efficiency and reduced downtime. The non-contact laser process eliminates the need for ink drying or setup changes, which streamlines continuous runs of varied designs. You benefit from consistent, high-speed marking that enhances throughput without compromising precision or durability.

Durability and Longevity of Marks

Laser marking on plastics offers superior durability and longevity, creating permanent, high-contrast marks resistant to abrasion, chemicals, and UV exposure. In contrast, pad printing tends to produce marks that fade, scratch, or chip over time, especially under harsh environmental conditions. Industries requiring long-lasting identification or traceability often prefer laser marking due to its enhanced resistance and maintenance-free quality.

Cost Comparison: Initial and Operational

Laser marking on plastics involves higher initial equipment costs due to advanced technology and precision, but offers lower operational expenses as it requires no consumables and minimal maintenance. Pad printing has a lower upfront investment but incurs ongoing costs from inks, plates, and regular maintenance, increasing overall operational expenses over time. Choosing between laser marking and pad printing depends on production volume and long-term cost efficiency needs.

Environmental Impact and Safety

Laser marking on plastics generates minimal waste and eliminates the need for hazardous inks or solvents, significantly reducing environmental pollution. Pad printing involves chemical-based inks that may release volatile organic compounds (VOCs) and require proper disposal to prevent environmental harm. Laser marking enhances worker safety by avoiding exposure to toxic materials, whereas pad printing necessitates handling potentially harmful chemicals with adequate protective measures.

Choosing the Right Method for Your Application

Selecting the appropriate marking method for plastics depends on factors such as durability, precision, and production volume. Laser marking offers high-resolution, permanent results ideal for complex designs and long-lasting identification, while pad printing excels in cost-effective, multi-color graphics on varied surface textures. Evaluating material compatibility, desired label lifespan, and customization requirements ensures optimal performance and cost-efficiency for your application.

Laser Marking vs Pad Printing on Plastics Infographic

libmatt.com

libmatt.com