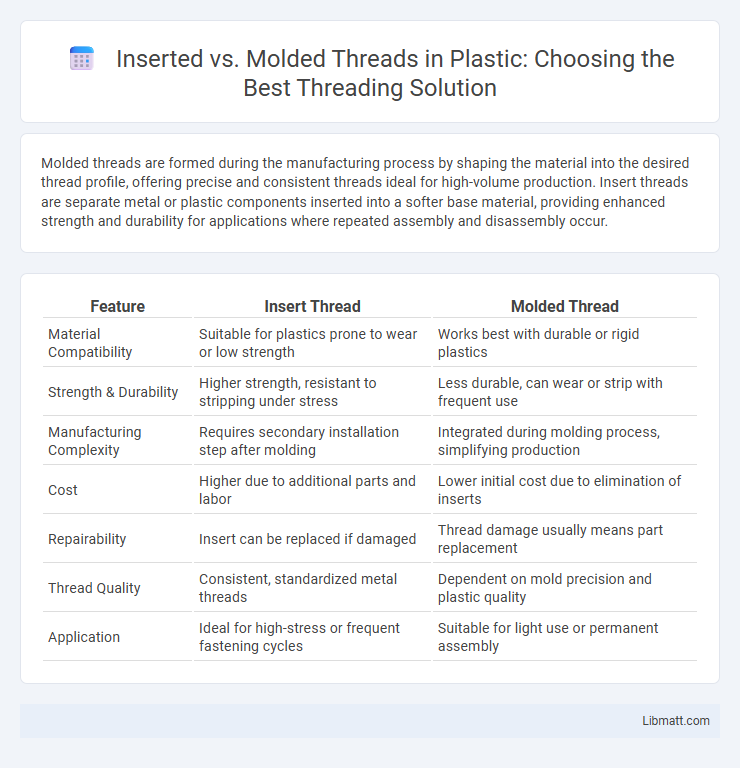

Molded threads are formed during the manufacturing process by shaping the material into the desired thread profile, offering precise and consistent threads ideal for high-volume production. Insert threads are separate metal or plastic components inserted into a softer base material, providing enhanced strength and durability for applications where repeated assembly and disassembly occur.

Table of Comparison

| Feature | Insert Thread | Molded Thread |

|---|---|---|

| Material Compatibility | Suitable for plastics prone to wear or low strength | Works best with durable or rigid plastics |

| Strength & Durability | Higher strength, resistant to stripping under stress | Less durable, can wear or strip with frequent use |

| Manufacturing Complexity | Requires secondary installation step after molding | Integrated during molding process, simplifying production |

| Cost | Higher due to additional parts and labor | Lower initial cost due to elimination of inserts |

| Repairability | Insert can be replaced if damaged | Thread damage usually means part replacement |

| Thread Quality | Consistent, standardized metal threads | Dependent on mold precision and plastic quality |

| Application | Ideal for high-stress or frequent fastening cycles | Suitable for light use or permanent assembly |

Introduction to Insert Thread and Molded Thread

Insert threads are metal or plastic components embedded into a base material to provide durable, wear-resistant threads for fastening, commonly used in softer materials like plastic or wood. Molded threads are directly formed during the manufacturing process of a plastic or metal part, shaping the thread as part of the original mold, often resulting in a less durable but cost-effective solution for permanent assembly. Both methods serve critical roles in mechanical design, balancing strength, precision, and production efficiency depending on the application requirements.

Key Differences Between Insert and Molded Threads

Insert threads are metal components embedded into a plastic or composite material, providing enhanced strength and durability, especially in high-stress applications. Molded threads are formed directly during the molding process, offering cost-effective and lightweight solutions but typically less resistance to wear and stripping. Your choice depends on factors like load requirements, production volume, and material compatibility, with inserts favored for high-performance or reusable fastening needs.

Advantages of Insert Thread Design

Insert thread designs provide enhanced durability by distributing load stress more evenly, reducing wear and fatigue in high-stress applications. They offer superior resistance to corrosion and stripping compared to molded threads, improving the longevity of assemblies in harsh environments. Insert threads also allow for easier repair and replacement without compromising the integrity of the surrounding material.

Advantages of Molded Thread Solutions

Molded thread solutions provide enhanced durability by integrating the thread directly into the component during manufacturing, reducing the risk of stripping or wear compared to insert threads. These threads offer improved precision and consistency, resulting in better alignment and torque distribution for your assemblies. Molded threads also streamline production by eliminating the need for separate thread insertion steps, reducing assembly time and costs.

Material Compatibility for Threads

Insert threads offer superior material compatibility for softer substrates such as plastics and composites by providing durable metal reinforcement, preventing wear and stripping. Molded threads, directly formed during molding processes, suit thermoplastics and materials capable of precise shaping but may exhibit lower strength and wear resistance under heavy loads. Choosing between insert and molded threads depends on the substrate's mechanical properties, with inserts enhancing compatibility in lightweight or flexible materials requiring repeated assembly.

Manufacturing Process Comparison

Insert threads involve embedding a pre-formed metal coil or nut into a softer material, typically using heat or ultrasonic insertion techniques, enhancing durability in plastics or composites. Molded threads are created directly during the casting or injection molding process by integrating thread forms into the mold, which reduces post-processing steps but may result in less robust thread strength. Your choice depends on factors such as production volume, material compatibility, and required thread performance in the final application.

Cost Implications: Insert vs Molded Threads

Insert threads typically entail higher initial costs due to additional components and installation labor, making them more expensive upfront compared to molded threads. Molded threads reduce manufacturing complexity and material use, leading to lower production costs but may sacrifice some strength and durability in high-stress applications. Cost-effectiveness depends on factors such as production volume, application requirements, and expected load conditions.

Performance and Durability Considerations

Insert threads provide enhanced durability by distributing load more evenly and resisting wear in softer materials like aluminum, while molded threads offer cost-effective solutions but may suffer from reduced strength and quicker degradation under repetitive stress. Performance in insert threads generally exceeds molded threads due to superior resistance to stripping and deformation, making them ideal for high-stress applications. Your choice should weigh long-term performance needs against initial manufacturing costs, especially in environments demanding repeated assembly and disassembly.

Common Applications for Each Thread Type

Insert threads are commonly used in high-stress applications like automotive engines, aerospace components, and heavy machinery where strong, wear-resistant threads are essential. Molded threads are frequently found in plastic housings, consumer electronics, and lightweight equipment where cost-effective and quick manufacturing is prioritized. Your choice depends on whether durability or manufacturing efficiency is more critical for the application.

Choosing the Right Thread Solution for Your Project

Choosing between insert threads and molded threads depends on factors like load capacity, material strength, and production volume. Molded threads offer a cost-effective solution for thermoplastics with moderate strength requirements, while insert threads provide superior durability and resistance to wear in high-stress applications. Evaluating Your project's mechanical demands and environmental conditions ensures optimal thread performance and longevity.

Insert thread vs molded thread Infographic

libmatt.com

libmatt.com