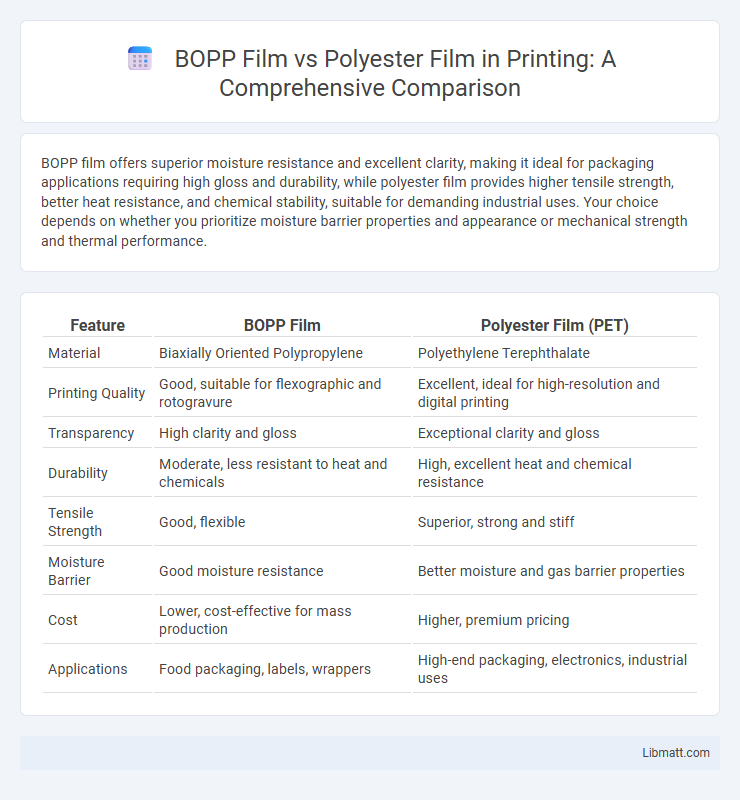

BOPP film offers superior moisture resistance and excellent clarity, making it ideal for packaging applications requiring high gloss and durability, while polyester film provides higher tensile strength, better heat resistance, and chemical stability, suitable for demanding industrial uses. Your choice depends on whether you prioritize moisture barrier properties and appearance or mechanical strength and thermal performance.

Table of Comparison

| Feature | BOPP Film | Polyester Film (PET) |

|---|---|---|

| Material | Biaxially Oriented Polypropylene | Polyethylene Terephthalate |

| Printing Quality | Good, suitable for flexographic and rotogravure | Excellent, ideal for high-resolution and digital printing |

| Transparency | High clarity and gloss | Exceptional clarity and gloss |

| Durability | Moderate, less resistant to heat and chemicals | High, excellent heat and chemical resistance |

| Tensile Strength | Good, flexible | Superior, strong and stiff |

| Moisture Barrier | Good moisture resistance | Better moisture and gas barrier properties |

| Cost | Lower, cost-effective for mass production | Higher, premium pricing |

| Applications | Food packaging, labels, wrappers | High-end packaging, electronics, industrial uses |

Introduction to BOPP and Polyester Films

BOPP film, short for Biaxially Oriented Polypropylene, is a versatile packaging material known for its clarity, moisture resistance, and excellent printability. Polyester film, also called PET film, offers superior strength, thermal stability, and chemical resistance, making it ideal for high-performance applications. Your choice between BOPP and polyester film depends on specific requirements such as durability, flexibility, and application environment.

Composition and Material Structure

BOPP film is made from biaxially oriented polypropylene, featuring a crystalline polymer structure that offers excellent clarity, strength, and moisture resistance. Polyester film, primarily composed of polyethylene terephthalate (PET), exhibits a denser molecular structure with superior thermal stability, tensile strength, and chemical resistance. The difference in polymer composition directly influences their mechanical properties and suitability for various packaging and industrial applications.

Manufacturing Processes Compared

BOPP film is manufactured through a sequential biaxial orientation process involving extrusion, stretching in both machine and transverse directions, and heat setting, which enhances its clarity and strength. Polyester film production uses a molten polymer extrusion followed by biaxial stretching at elevated temperatures, resulting in improved tensile strength and dimensional stability. While both films undergo biaxial orientation, BOPP's manufacturing uses polypropylene resin with simpler processing, whereas polyester film requires more complex temperature control and crystallization steps for superior thermal resistance.

Physical and Mechanical Properties

BOPP film exhibits superior tensile strength and excellent moisture barrier properties, making it ideal for packaging applications requiring durability and flexibility. Polyester film offers higher thermal stability, greater dimensional stability, and superior resistance to abrasion and chemicals, allowing it to perform well under harsh environmental conditions. Both films differ in surface hardness, with polyester typically providing a smoother, more scratch-resistant surface compared to the softer, more pliable BOPP film.

Optical Clarity and Appearance

BOPP film offers excellent optical clarity with a bright, glossy surface that enhances the visual appeal of your packaging, making graphics and colors pop vividly. Polyester film, however, provides superior clarity with higher transparency and better resistance to haziness over time, ideal for premium display applications. Both films maintain strong appearance qualities, but polyester is often preferred when long-term clarity and durability are critical.

Barrier Properties: Moisture and Gas

BOPP film exhibits excellent moisture barrier properties, making it ideal for protecting products from humidity and preventing moisture ingress. Polyester film offers superior gas barrier performance, effectively reducing oxygen transmission to preserve product freshness and extend shelf life. Combining these films can optimize protection against both moisture and gas, enhancing packaging efficiency for sensitive goods.

Printability and Surface Treatment

BOPP film offers superior printability due to its smooth surface and inherent compatibility with various inks, making it ideal for high-quality graphic applications. Polyester film requires surface treatment such as corona or plasma treatment to enhance ink adhesion and water-based or solvent-based coating compatibility. Both films benefit significantly from surface treatments aimed at improving the anchorage of inks and coatings, but BOPP's natural printability reduces the need for extensive pretreatment.

Applications Across Industries

BOPP film excels in packaging, labeling, and lamination due to its high clarity, moisture resistance, and cost-effectiveness, making it ideal for food, pharmaceutical, and consumer goods industries. Polyester film offers superior mechanical strength, chemical resistance, and thermal stability, preferred in electrical insulation, solar panels, and flexible electronics applications. Your choice depends on specific industry requirements such as durability, transparency, and environmental exposure.

Environmental Impact and Recyclability

BOPP film offers superior environmental benefits due to its high recyclability and lower energy consumption during production compared to polyester film. Polyester film, while durable, has a greater environmental footprint because it relies on petroleum-based raw materials and is less widely recycled. Choosing BOPP film supports your sustainability goals by reducing waste and promoting circular packaging solutions.

Cost Analysis and Market Availability

BOPP film generally offers a lower cost per unit compared to polyester film, making it a preferred choice for budget-sensitive packaging applications. Polyester film commands higher prices due to its superior strength, clarity, and temperature resistance, impacting its market allocation towards premium and specialty uses. The global supply chain for BOPP is more extensive, ensuring broader market availability, while polyester films tend to have a more niche distribution concentrated in industrial and high-performance sectors.

BOPP film vs polyester film Infographic

libmatt.com

libmatt.com